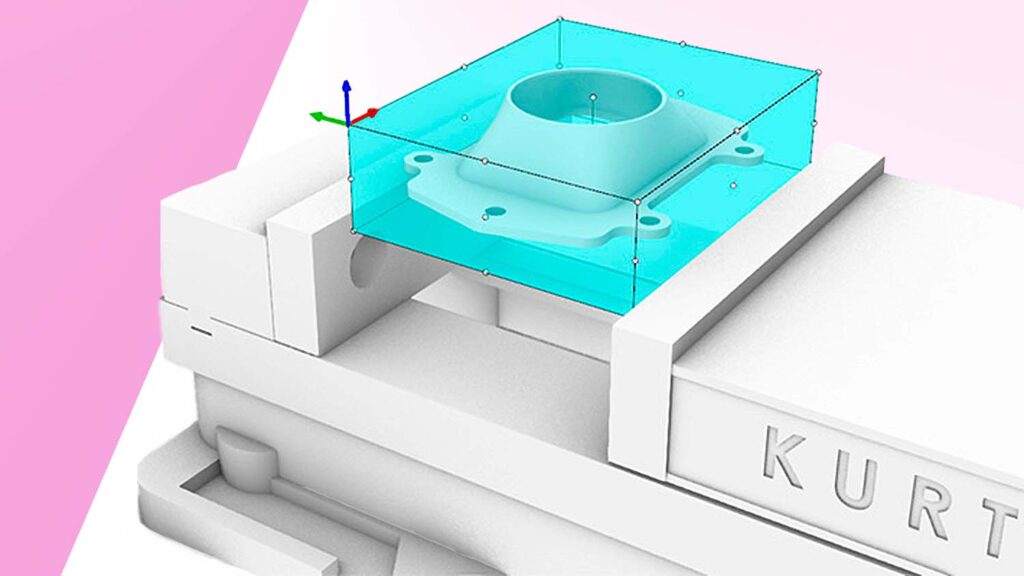

BobCAM for Rhino is the latest CAM Software plug-in for Rhino 6 or 7 users, boasting the CAM experts’ features and toolpath technology in Rhino’s native design environment.

The software adds more toolpath options and better workflow to create toolpath, verify programs and post to CNC equipment.

BobCAM for Rhino offers users the ability to program, simulate, report and post G-code programs, alongside an entire family of more specialist modules including milling, turning, 3- and 5-axis machining, wire EDM and toolpath simulation.

“BobCAM for Rhino integrates CAD and CAM functions in a single setting thus enabling a seamless transition from the design process to toolpath programming, simulation, and G-code processing,” said a BobCAM spokesperson.

“At BobCAD-CAM software is developed by machinists for machinists. Many of the software engineers began their careers programming, setting up, and operating CNC machines in manufacturing companies. Their understanding of the industry creates effective solutions for day-to-day business.”

BobCAM for Rhino Features

Mill Standard

Add more toolpath and CAM features for different stock shapes, pocketing scenarios, and 3D roughing and finishing. Great for job shops, OEM’s, wood workers, prototypers, and more.

Mill Professional

Get even more 3D machining options and strategies best for more complex 3D machining projects. Great for die, mold, and tooling applications.

Mill Premium

Add maximum control over your 3D machining as you step into the entry level world of multiaxis. Surface based toolpaths ( typically used for 4 & 5 Axis ) with options and advanced settings toimprove surface finishes and cycle times. Great for advanced tooling shops.

Mill 4 Axis Standard

Add on toolpaths and CAM features to program 4 axis indexing (positional), wrapped (axis substitution), and rotary (model based 4 axis machining).

Mill 4 Axis Professional

Get True 4 axis toolpaths by unlocking 4 axis specific options of surface-based toolpaths with advanced model based 4 axis machining for roughing and finishing.

Mill 5 Axis Standard

Add on wire frame toolpaths with 5 axis tilt control, 5 axis drilling, and indexing with G68 ( or equivalent ) coordinate rotation support.

Mill 5 Axis Professional

Get all of our toolpaths and options for 2-5 axis machining. Unlocking all of the toolpaths and options BobCAM offers for CNC Milling.

2 Axis Lathe

CAM software for 2 axis cnc lathes to post g-code programs for: Drilling, Facing, Turning Grooving, Threading, Cutoff stock handling and more.

Mill Turn

CAM software for 3 – 5 axis lathes supporting C, Y, B axis programming. Single and multiple spindles and turrets are supported with special programming features for part transfers, and auxiliary functions.

Wire EDM

CAM software for 2 & 4 axis Wire EDM programming. Multiple toolpath options and settings for: Open shape cutting, inside, outside, land, taper, and 4 axis synchronisation.

Probing

Simplify and automate the process of programming, simulating and posting of CNC Probing cycles.

NC Editor Professional

Powerful, easy to use G-code editing, simulation and DNC communications in your hands. Graphic display, and edit your NC programs for 2, 3, and 4 Axis Milling or 2 Axis turning routines.

BobART

Apply creative artwork to your cnc projects by vectorising images and using our V-carving toolpath. BobART also included CAD features to develop relief models like adding logos and other aesthetics to 3D projects.

Machine Simulation

Check for collisions and toolpath errors against virtual machine components, tool and holders, fixture, stock and workpiece.

BobCAM For Rhino Toolpath Options:

Software configurations to meet the programming requirements for 2- 5 axis CNC equipment.From desktop CNC routers to the industry’s best CNC production equipment.