A new target frame from Aesub sets small objects into the perfect position for 3D scanning, as the company looks to simplify the measurement process of front and back scans.

The key benefit is that reference points required for scanning can be placed directly on the frame instead of on the object. This can save a lot of time, especially during a repetitive measurement of identical objects such as for small batches or pre-series.

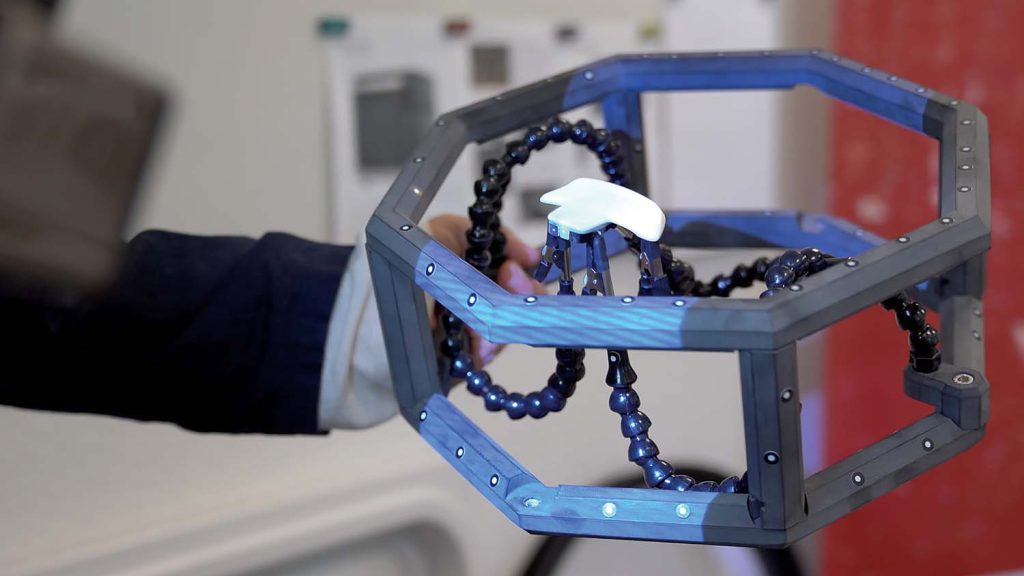

The Aesub Target Frame comes as a modular kit, that when assembled creates a 200mm or 300mm diameter, with plug and screw connections directly integrated to it.

The 3D printed frame is mapped with reference dots, and due to its manufacturing method weighs only half that of a conventionally manufactured aluminium frame the same size.

Flexible arms with clamps hold the object within the black frame so that it can be scanned from all angles.

Aesub says that its Target Frame also simplifies the measuring process of single parts that require front and back scans: Without a target frame, such parts would have to be covered with many reference points so that overlapping points are visible from both sides.

The modular frame can be adjusted to the size of the measured object, allowing for the optimum distance between the measuring points and the measuring object is always maintained.

Aesub is more commonly known for its range of vanishing aerosol sprays for use in 3D Scanning workflows, available in rattle-can form or as a formula for use in a spray gun system for 3D scanning large parts.