Desktop Metal is reportedly set to unveil a new FreeFoam resin that once 3D printed can be then heat-activated at a later date to produce foam parts for use in sports shoes, cars and other industries, reports Reuters.

By 3D printing a ‘compact’ foam, the material is expanded at a later date using an oven, most likely at the final point of assembly, which would help manufacturers when shipping and storing parts.

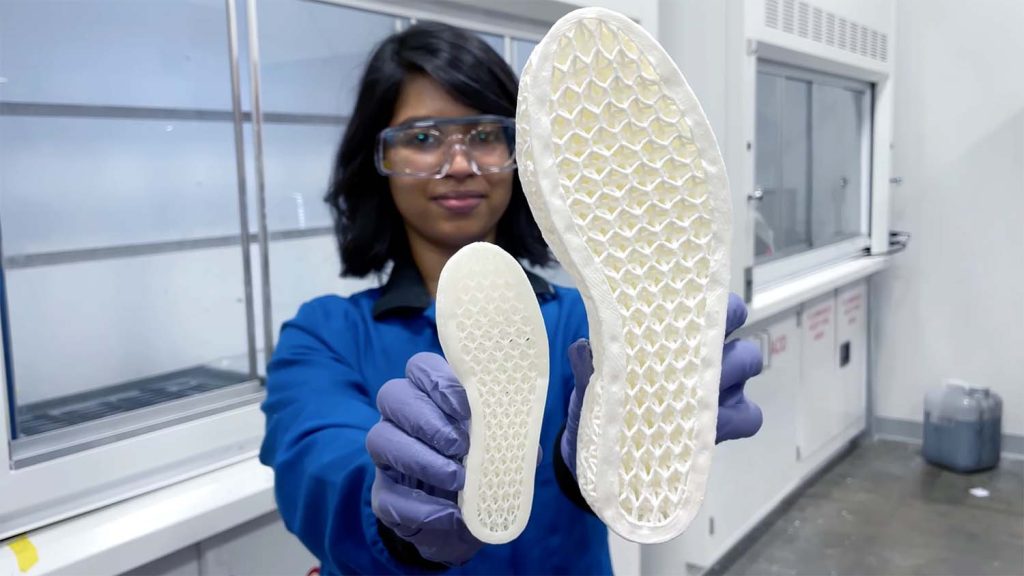

As it is 3D printed in its initial state, the design can take advantages of custom forms and lattices.

Speaking to Reuters, Desktop Metal CEO Ric Fulop said that the new method will allow manufacturers to 3D print the exact shape and durability that they want, but lighter and without the issues around transporting it.

He said, “You ship your part tiny and then in the local factory where you’re going to use it, the part blows up and that gives you a better supply chain, but also it is greener,” further suggesting that the weight of a car seat part can be cut “by two-thirds doing this”.

You can read the full story on Reuters here.

Desktop Metal has expanded the reach of its 3D printing technologies in recent years beyond its initial PBF metals technology. In 2019 it moved into the continuous fibre FDM sector with its Fibre technology, and more recently it has acquired rival metals AM company ExOne, and took a step into resin technologies with the acquisition of EnvisionTec in February this year.

It’s unknown as yet whether the FreeFoam technology will work on existing legacy EnvisionTec hardware – now rebranded ETEC – but judging by the launch video (below) there looks set to be a new line-up of large volume Desktop Metal 3D Printer technology for this new resin to enable parts such as full car seat cushions.