Stratasys’ Infinite Build concept adds automation to the FDM process, to the delight of manufacturers

Despite falling from mainstream attention, 3D printing technologies are still developing at pace as the focus towards end-use parts becomes the new battleground.

The key factors of materials, repeatability, scale and speed are all improving, and as a result, 3D printing has grabbed the attention of mainstream manufacturers across all industries.

Few are better placed to confirm this than Stratasys. One of the original ‘Big Two’ 3D printing companies, alongside 3D Systems, it is now faced with much wider competition as it looks to develop technology to take manufacturing to the next level.

Having invited us to its headquarters in Eden Praire, Minnesota, USA, the company unveiled its latest concept machines as it looks to push the boundaries of one of its strongest products – Fused Deposition Modelling (FDM) – which Stratasys founder Scott Crump developed over 30 years ago.

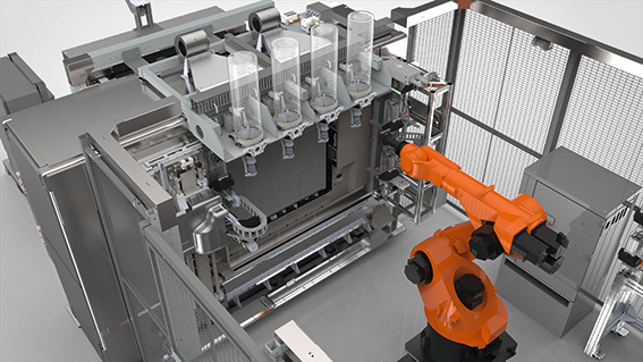

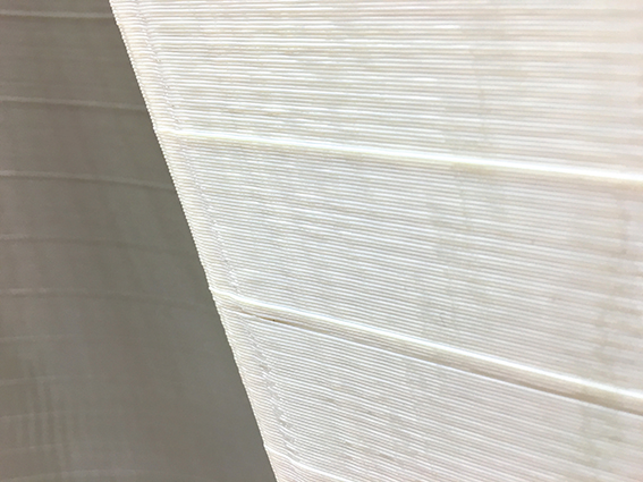

The first machine, Infinite Build, has flipped the traditional FDM 3D printing process on its side and grows parts horizontally from the build platform that are, in theory, of infinite length.

The addition of new micro pellet material canisters allows for increased automation of stock fills and material changeovers in what is a multi-material machine. While detailed realtime print feedback is already enabled, there’s also scope to add other tools to the arm controlling the printhead, such as metrology inspection or even CNC machining tools.

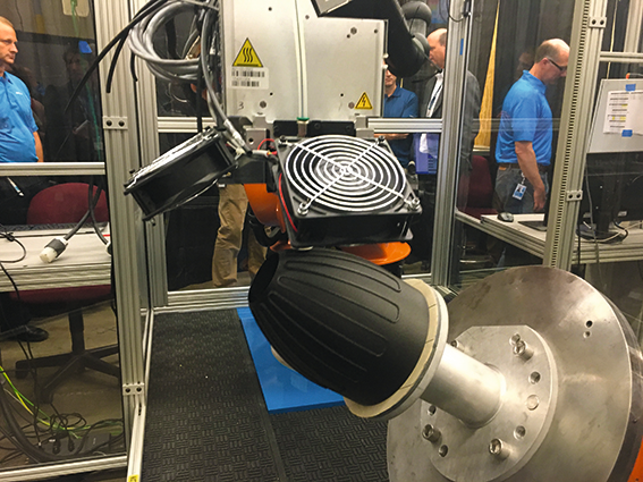

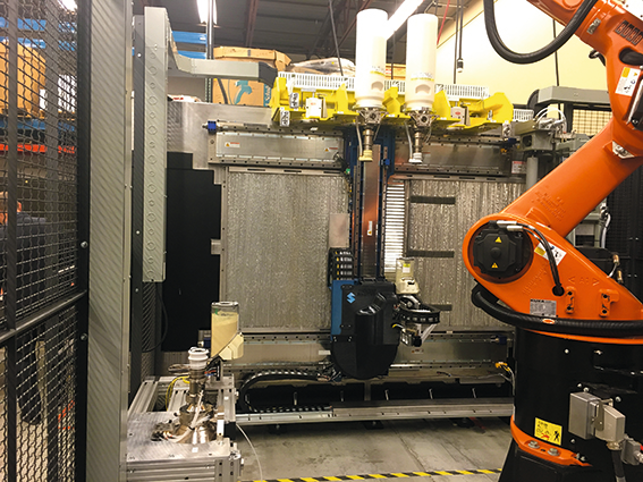

The second new machine, positioned behind a plexiglass shield, relies on the ability of a giant orange robotic arm and turntable that combine to create a 3D printer extruder head with 11 degrees of freedom – removing the need for build supports and allowing for continuous thread layering for composite materials like carbon fibre.

Both are developments on existing technologies, featuring upgrades most notably to printheads and materials stock, but both have captured the imagination of manufacturers looking to build parts of ever more complicated shapes from plastics and composites.

“We don’t see the development as moving away from prototyping toward serial part manufacturing. We see them as complimentary,” suggests Scott Sevcik, Stratasys’ director of manufacturing platform development. “In fact, it increases the demand.

“Today, our technologies are used to prototype parts that are then manufactured with another means. As a result, we don’t fully utilise the design freedom of 3D printing in prototyping, because we must consider the limitations of the final production method.

“When a part is being designed to utilise the design freedom and will be in production as a printed part, there is no other way to prototype that part than with 3D printing.

So as we see increased adoption in production additive manufacturing, we see prototyping growing to support.”

With 11 axis of movement, the Robotic Composite 3D Demonstrator adds automation to composite thermoplastic builds — like this missile nose cone

Materials magic

The ability to print high performance thermoplastics that have direct relevance in manufacturing means there has already been an adoption of existing technologies for production parts in aerospace – such as some non-flight critical parts on current Airbus models.

However, the increase in part size from the Infinite Build concept machine and the certified strength of plastics such as Stratasys’ Ultem material, now allow for entire passenger aircraft interior panels to be produced. Customised logos can be added to each panel without the need for individual tooling, while other parts – such as hooks and fasteners – can be built into a single part.

While new players to the industry have announced open source materials development by third parties, Stratasys is continuing to develop its range of thermoplastics in-house.

While this might seem limiting, the company cites that materials development forms a large portion of its sizeable R&D budget, which totalled at $90 million across all departments over the last four financial quarters.

This spans the current ‘off the shelf’ range of FDM materials, while customers needing more made to measure characteristics can call on Stratasys’s research and development team to create a ‘development material’.

Stratasys had developed FDM Ultem 9085 for aircraft interior parts, however Airbus and other aerospace customers required material traceability and assured consistency in order to use the material in applications certified by the FAA.

As a result of this experience Stratasys introduced its ‘certified material products’, a range of verified materials that is in the process of rapidly expanding.

“In manufacturing, the application dictates the properties required of the material. We’ve had customers approach us with fantastic applications, but the available material set couldn’t meet the needs.

Earlier this year, for example, NASA disclosed that they had installed several parts for a satellite that we had printed in a custom-developed ESD PEKK [Electrostatic Discharge resistant Polyetherketoneketone] material to meet their requirements. More materials with properties targeting specific applications or use cases, such as this, will be key to expanded adoption in manufacturing,” suggests Sevcik.

One additional change to the Infinite-Build and Robotic-Composite machines is that Stratasys is exploring alternate feedstocks with its users, such as the micro-pellet format being used in the concepts.

“There are a number of advantages to this approach, and we’re using it here to demonstrate a faster, highly controlled extrusion approach that is also continuously re-fillable. This enables long term, lights-out, operations as well as introducing new possibilities in combining and functionally grading materials.”

Automating the materials changeovers adds speed and variability to the FDM process

Automating composites

Stratasys’ expansion into composites comes at a time where many industries are looking to replace metals for weight savings, but it also comes at a cost due to the high amounts of labour involved.

As high volume industries look to adopt more composite parts, automation of part production is necessary, hence the excitement surrounding the 11-axis Robotic Composite 3D Demonstrator, which also eliminates the geometric constraints imposed by the current composite lay-up processes.

“When we can combine the design freedom of 3D printing with the material advantages of composites, we unlock entirely new classes of parts,” says Sevcik, a ‘CNC machining man’ by his own description, who is clearly excited by the direction things are taking.

Stratasys has worked hard to increase its number of certified materials for end use parts

“OEMs replace metal parts with composite parts to save weight. If we can optimise the geometry without the constraints of the manufacturing method, as we are able to do with 3D printing, we can take already lightweight composite parts and make them even lighter by only using the material necessary to carry the design load.”

An age of composites and advanced thermoplastics is upon us, and as more designers look to take advantage of such materials, it will be down to the likes of Stratasys to ensure new found design freedoms emerging from CAD and simulation tools can be built to industry standards.

Stratasys’ latest 3D printing technology takes manufacturing to the next level

Default