Coreform has won a substantial US government grant to explore a new method for simulating complex lattice structures within additively manufactured parts.

Lattice structure patterns are becoming attractive to auto and airplane engineers because of their high strength-to-weight ratios and are common place in the additive tech demonstrator world. That said, these structures are highly complex to analyse for stress reactions or collapse responses.

Utah-based Coreform lattice simulation technology claims that it might solve this problem.

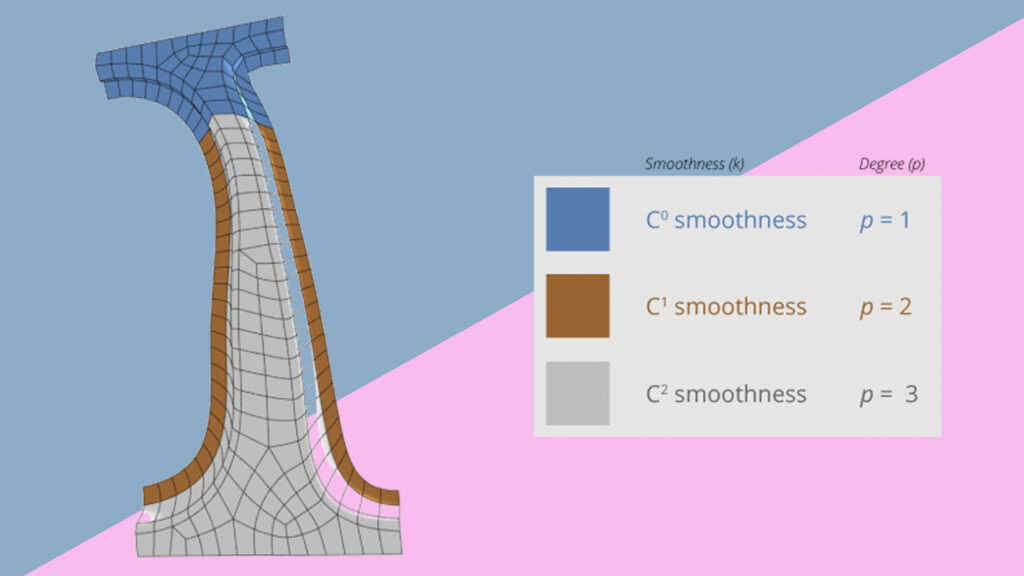

Its patented flexible isogeometric analysis (Flex IGA) approach to simulation can “handle the complexities of lattice structures with a much lower computational burden.”

The grant will allow the team to begin developing software for simulation of the lattice structures. This grant, offered through the Federal Small Business Innovation Research (SBIR) program, is designed to support small businesses in pursuing innovative solutions to technological problems.

The low-weight approaches enabled by lattice structures make the parts more complex to validate through simulation, because now the lattice microstructure has to be “meshed” into thousands of tiny elements.

The work of dividing those lattice structures into tiny parts for computation is too difficult and time-consuming to be practicable for any but small and simple parts. Coreform’s Flex IGA process may make it possible to subdivide, or “mesh”, these complex microstructures with a minimum of time and expense.

It anticipates using the SBIR grant to computer simulate a 3D-printed lattice structure that is more than ten times larger than any lattice structure that can be simulated today.

Coreform was founded by Matt Sederberg, former CEO of t-Splines along with other luminaries from the academic simulaiton world.