Volkswagen is providing suppliers with 3D data based on EPLAN Pro Panel as part of its VASS (Volkswagen Audi Seat Skoda) Standard, looking for complete digital twins of control cabinets and the components within to be integrated into automotive projects.

For suppliers, the new release of VASS creates the foundation for adopting and expanding automated manufacturing processes in control cabinet and switchgear system engineering.

These range from mechanical NC machining to automated terminal assembly, as well as wire processing and wiring support.

Companies benefit from the fully developed design templates provided by Volkswagen that can be used as a basis for faster and higher-quality system engineering, manufacturing and commissioning.

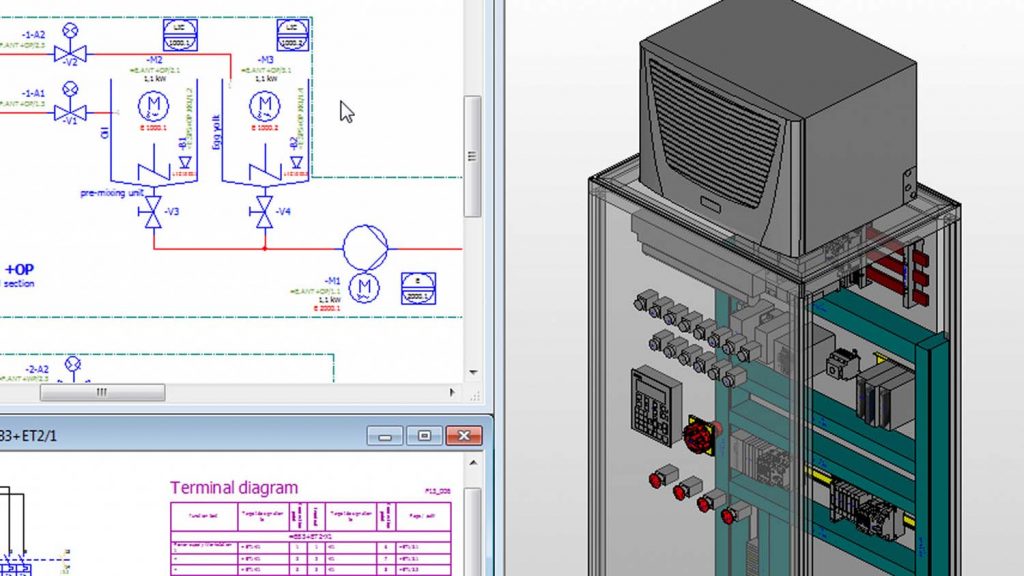

The updated VASS Standard for suppliers includes an update to EPLAN Version 2.9, and has been expanded to include 3D functionality in switchgear system engineering and information for bi-directional exchange with PLC project planning tools.

“The additional 3D functionality provided by EPLAN Pro Panel makes it possible to directly derive manufacturing information for automated control cabinet and switchgear system engineering,” explained Chris Olds, strategic account manager at EPLAN UK.

“Engineering projects further benefit from the integrated collision check and thermal power dissipation considerations for components, enabling optimised component placement in the cabinet and a more energy-efficient design with Rittal climate control systems.”

As an extra benefit, key control technology information has been added to device and project data, which enables bi-directional data exchange between EPLAN (hardware engineering) and the Siemens TIA Portal (software project planning) using the AML interface.

“This innovation considerably reduces the time spent on system planning since the PLC hardware structures, pre-defined inputs and outputs and bus topologies can be imported directly from EPLAN, alongside the exact port wiring,” Olds added.

“During plant system operations and for later modifications or expansions, the information from TIA Portal can be fed back into the EPLAN project.

“This ensures uniform, error-free plant system documentation ‘as built’ and shorter entry processes for integration into digital production management.”

Volkswagen is said to be working on further developing automation standards which, when complete, will be passed down to the company’s suppliers.

“This expansion of the VASS Standard with the newest aspects of EPLAN engineering software and Rittal system technology means we’re supporting our suppliers in realising digital and automated manufacturing processes,” said Daniel Gräser of the division for manufacturing automation and digital production at Volkswagen.

“At the same time, we are taking an important step along the path we’ve started towards the digital factory.”