DyeMansion has announced a new post processing set-up for the newly launched Stratasys H350 3D printer, capable of fine tuning surface finish and part colour.

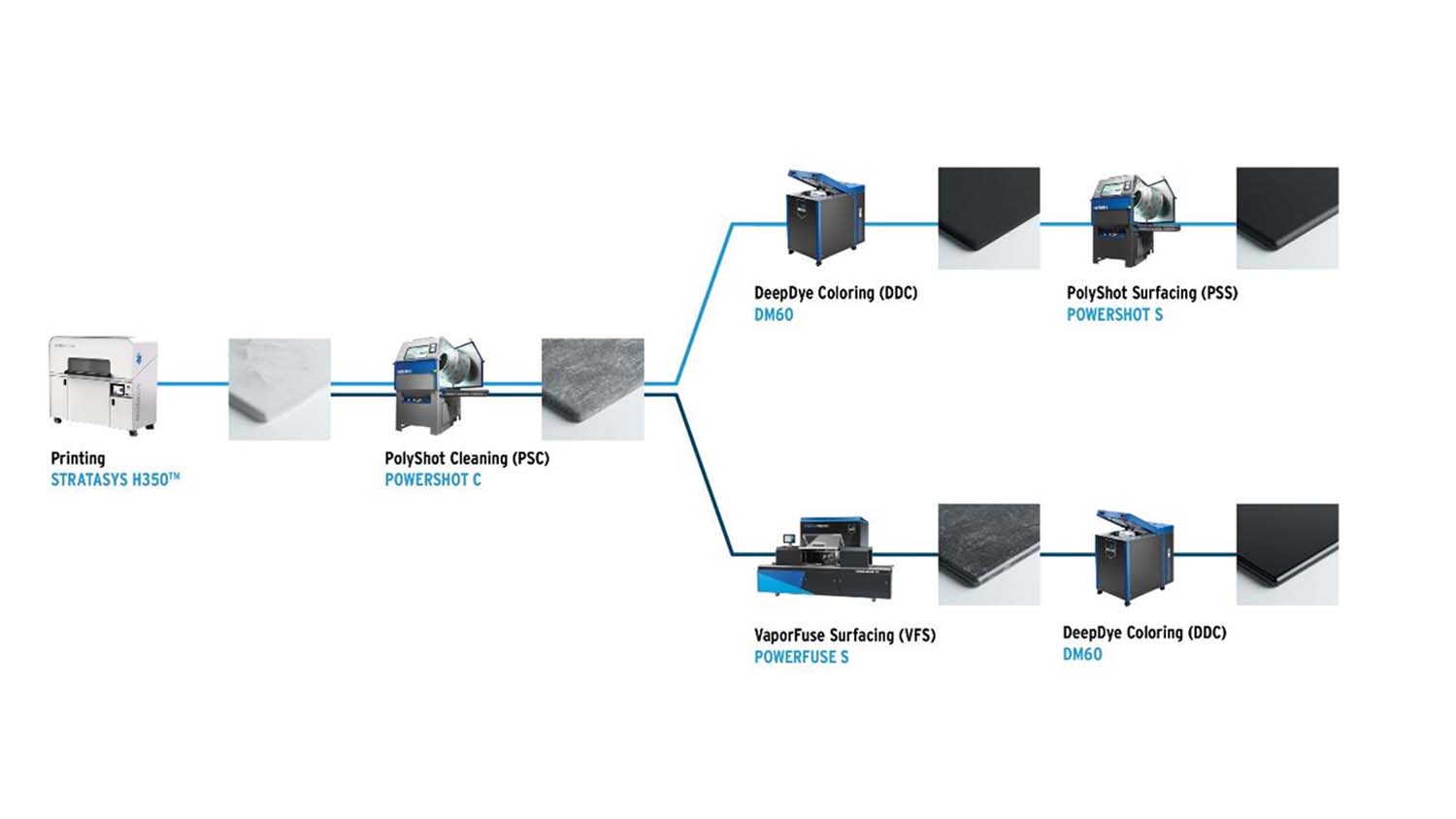

The DyeMansion Print-to-Product workflow can be used for cleaning, surfacing, and colouring parts depending on the end-use application requirements.

Users can choose between two different finishes: an aesthetic semi-gloss finish delivering a homogeneous scratch resistant surface, or a more functional finish delivering completely sealed and washable surfaces.

The Print-to-Product workflow should enables various applications for Stratasys H-Series technology such as eyewear, automotive interior or spare parts, and medical devices and orthotics.

“Together with DyeMansion, we’re giving our customers a comprehensive, proven additive manufacturing process tailored to our H350 3D printer. This enables our customers to easily move from powder to consistent, quality finished parts at scale,” said Patrick Carey, senior VP, Americas products and solutions, Stratasys.

Carey added,: “The alliance will help accelerate the adoption of SAF technology for end-use parts production.”

DyeMansion CEO Felix Ewald, said: “We are extremely happy that Stratasys has partnered with us to create this reference architecture. Together we are able to deliver best-in-class solutions to our customers and demonstrate the value of combining their new SAF technology with our solutions to enable high-value and high-volume applications across various industries,

“The future of industrial 3D printing starts here. We are very excited about our partnership and are even more excited to see where our partnership will take us.”

To further complement the initial solution architecture, both companies are working on a joint go-to-market strategy that will provide customers with solutions across various applications.

Together they plan to advance the reference architecture with solutions for different applications and the process chain will be continuously updated with new state-of-the-art technology from both companies.

The reference architecture will be installed on-site at Stratasys Direct later this year and once successfully installed, the whole factory concept will be made accessible for interested parties in the form of factory tours or on-site workshops.