Zortrax has launched two AM sets Full Metal Package 17-4 PH and Full Metal Package 316L as well as the new filament Victrex Paek AM 200, designed to be extruded at lower temperatures, having a lower melting point than Peek.

Each Zortrax Full Metal Package was developed to offer all the essentials for an easy start with metal 3D printing and should include either Basf Ultrafuse 316L or Basf Ultrafuse 17-4 Ph metal-polymer filaments patented by Basf Forward AM.

Victrex AM 200 low-melt Paek filament is a high-performance polymer from the same thermoplastics family as Z-peek, which promises to offer similar, or even improved, 3D printing results.

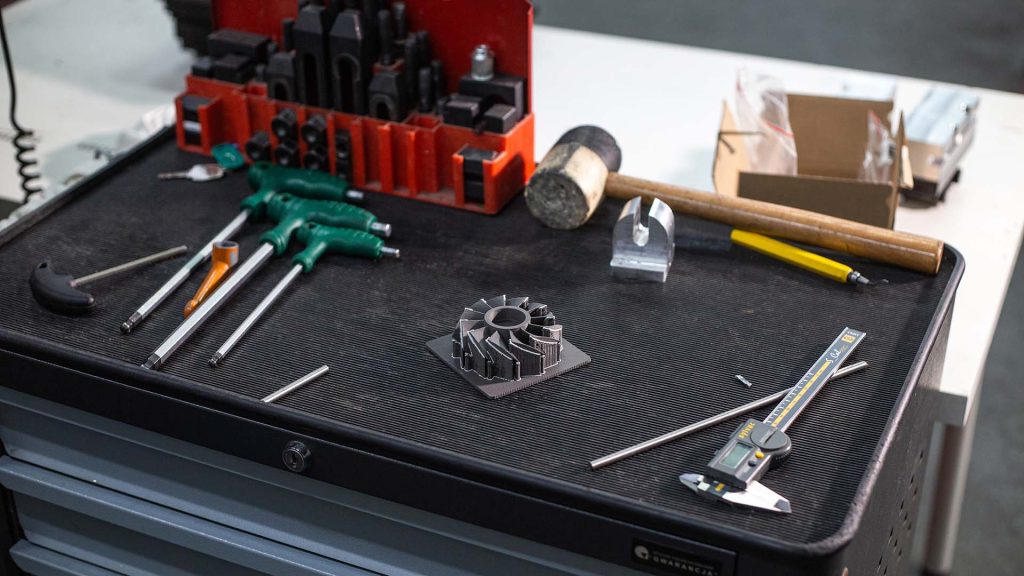

The metal 3D printing technology developed by Basf Forward AM involves using metal-polymer filaments to produce industrial-grade, stainless steel components.

Compared to traditional production technologies, such as CNC machining or metal injection moulding, metal 3D printing aims to ensure greater design flexibility and be more affordable.

To use 3D printing with metallic powder filaments at their maximum potential, users need access to a quality, reliable 3D printer, capable of processing them properly, says Zortrax, as well as the appropriate post-processing technologies. Zortrax aims to encompass all these aspects of production.

“When using metallic powder filaments for metal 3D printing, micro-cracks or brittle spots on the models are the common issues users struggle with. The reason is usually the improper inner structure, which prevents the target items from preserving all the properties desired for metal,” said Zortrax head of R&D Michał Siemaszko.

“Being aware of that, we focused on creating the solution, ensuring that models have the right structure, allowing them to be applied just like regular steel. We succeeded, as it is obtained on Zortrax Endureal during the very printing process. Moreover, our new Zortrax Full Metal Packages come together with, amongst other elements, high-quality metal-polymer filaments by BASF Forward AM, and a voucher for professional post-processing in Elnik Systems GmbH, where the 3D prints undergo proprietary catalytic debinding and sintering processes.”

Zortrax said Full Metal Package 316L includes Basf Ultrafuse 316L, a filament composed of 80% 316L stainless steel and 20% polymer, containing over 10% of chromium which, while in contact with oxygen, should cause a thin coating layer to form on the surface of the model, protecting it from corrosion.

The parts 3D printed with BASF Ultrafuse 316L should have up to 561 MPa tensile strength, 251 MPa yield strength, up to 53% elongation at break, and have a non-magnetic microstructure.

Zortrax said Full Metal Package 17-4 PH also contains Basf Ultrafuse 17-4 PH, an industrial composite filament, comprising 80% of 17-4 hardened steel and 20% of polymer content which should give parts up to 1004 MPa tensile strength, 764 MPa yield strength, up to 4% elongation at break, and have magnetic microstructure.

Zortrax Full Metal Package 316L and Zortrax Full Metal Package 17-4 PH, should both include additional components including Basf Ultrafuse Support Layer, Magigoo Pro Metal adhesive, an extra hotend module with brass nozzles for Zortrax Endureal, and a voucher for professional post-processing at Basf’s partner Elnik.

Finally, with Zortrax Endureal users should have access to Victrex AM 200 low-melt Paek filament, a polymer that belongs to the same thermoplastics family as Z-peek and that should offer low viscosity, assure easier flow through the nozzle and slow crystallisation rate.

“Victrex AM 200 has greater strength in the Z-axis than Peek, and comparable strength in the X and Y axes,” said Zortrax material development leader Dawid Piastowski.

“All the other parameters are similar to those of Peek. Paek, however, is much easier to print. This high-performance polymer is a great choice for 3D printing heavy-duty parts that can replace metal components in aviation, marine, advanced engineering, or oil industries. Paek can also be successfully used when 3D printing load-bearing components, elements of tools, structural frames, or parts that must withstand high temperatures.”