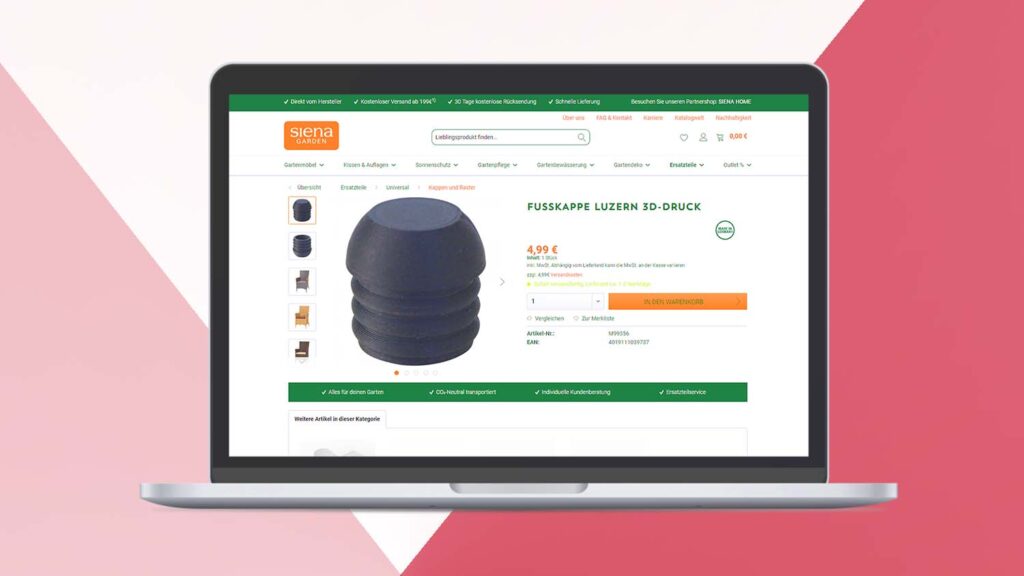

Replique has partnered with Siena Garden, a German garden furniture brand, to produce more than 1,000 3D printed foot caps or protection covers for the brand, breathing new life into garden chairs and contributing to a circular economy.

The integration of Replique’s 3D printing platform allows spare parts to be produced on-demand and locally, eliminating excessive inventory and avoiding huge minimum order quantities. This not only reduces costs for Siena Garden, it also enhances customer satisfaction with improved aftermarket services.

In addition to foot caps, the Siena Garden webshop offers other repair parts, such as handles, connecting and moving parts, designed for Holywood swings and garden loungers.

This follows their “Eternal Spare Parts” concept, founded less than 2 years ago it promotes sustainability by offering continuous replacement parts for garden furniture, extending the product lifespan and reducing waste.

This case shows that even for small, everyday parts, 3D printing can make a huge difference. Peter Benthues, CDO of H. Gautzsch Firmengruppe, the parent company of Siena Garden, remarked, “The collaboration with Replique has been another important step in our commitment to environmental responsibility and customer satisfaction. This milestone reinforces our pursuit of delivering long-lasting products.”

Henrike Wonneberger, COO and co-founder of Replique, expressed her excitement: “We are thrilled to celebrate this milestone with Siena Garden. By offering on-demand production without the burden of stockpiling and promoting repair, we aim to make a positive impact on our planet, one part at a time.”

Last year, Replique partnered with Alstom to help reduce complexities and allow the production of customised industrial-grade serial parts faster and more cost competitive for its rolling stock of trains. While Alstom has already used 3D printing for the production of spare parts, with the aid of Replique it has been able to fulfil specific customer needs using additive serial production.

How AM is being used by big brands to add new accessories and spare parts