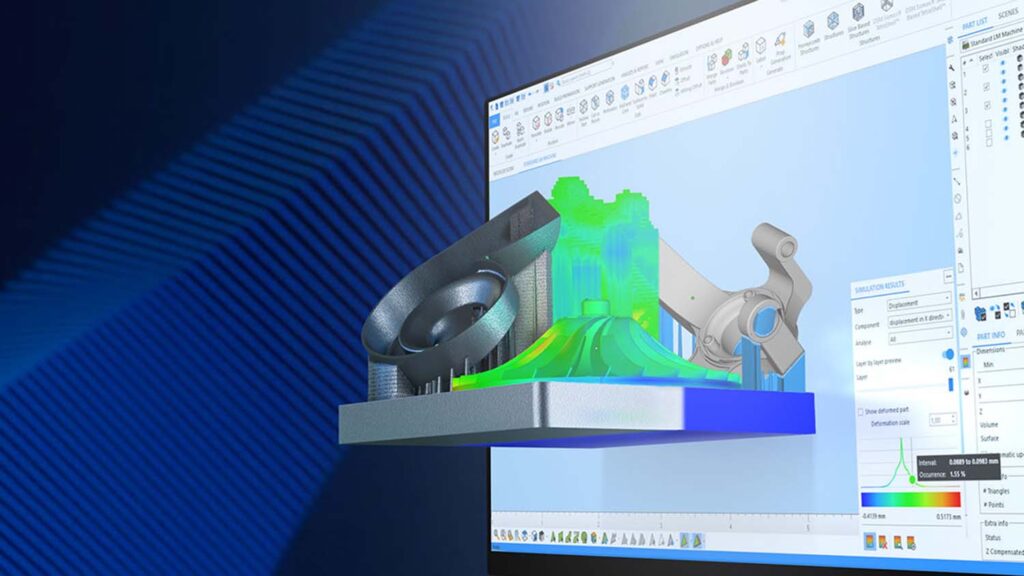

Materialise Magics has embedded native CAD workflows into its 3D printing build preparation and management software through integration of Siemens’ Parasolid Technology.

Through using Siemens Parasolid technology, Materialise says it will add native CAD workflows within Magics 26, providing an additional toolset on top of mesh functionality.

This combination increases the number of trusted solutions, letting users continue iterating CAD designs in Magics to prepare for additive manufacturing processes, with Materialise adding that it expects this to aid productivity and provide cleaner, more accurate and fit-for-purpose data for 3D printing parts.

Magics 26 will enable users to transition from design optimisation in CAD to mesh-based file preparation. This should enable AM system users to review and edit parts with the part’s designers and engineers who are more familiar with CAD systems, before transitioning to mesh for platform and build preparation.

Convergent Modeling technology, a core part of the Parasolid solution, enables mesh data to be mixed with traditional CAD geometry in a unified environment, removing the need for time-consuming and error-prone data translation and enabling intelligent operations to be carried out. Materialise says that Magics users will benefit from the best of both worlds – CAD for part editing using best-in-class technology and mesh-based operations for platform preparation using tried-and-true solutions.

“For years, the 3D printing industry has discussed whether CAD or mesh is the preferred workflow for file preparation,” said Materialise VP software Stefaan Motte. “We believe both offer unique benefits and a seamless integration of both formats will provide users with the optimal workflow.”

Magics 26 will be released in spring 2022, showcasing the new integrated workflow for 3D printing.