In the first steps towards making the benefits of 5G networks a reality, 5G-Encode has switched on the second phase of its network at the National Composites Centre (NCC).

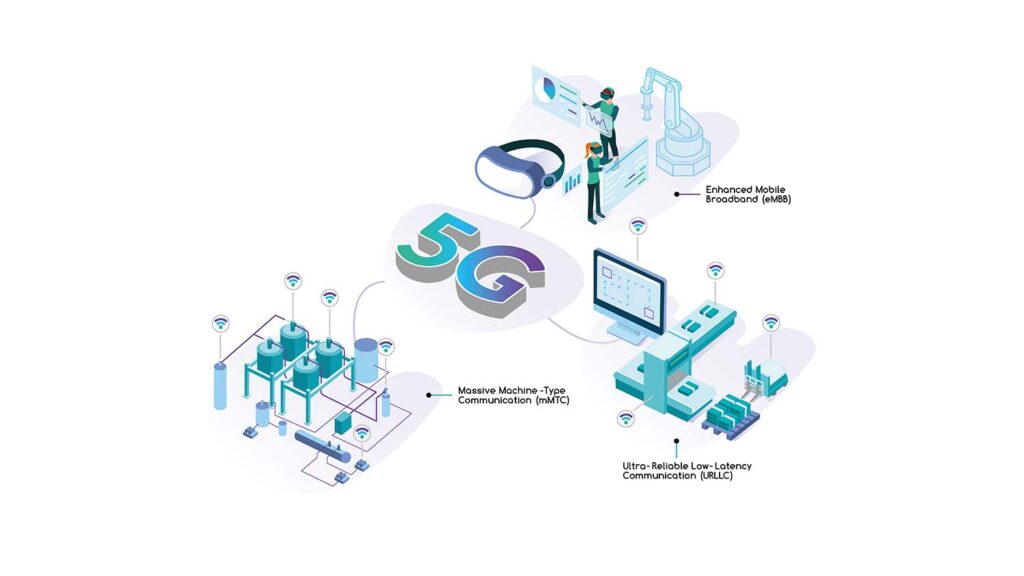

5G-Encode aims to prove the commercial benefit of 5G technology to enable three specific industrial use cases: VR and AR to support design, manufacturing and training; monitoring and tracking time sensitive assets; and wireless real-time in-process monitoring and analytics for equipment such as CNC machines and 3D Printers.

The 5G-Encode Project is a £9 million collaborative project aiming to develop 5G applications in manufacturing industry. Partially funded by the UK Government as part of their 5G Testbeds and Trials Programme, it is one of the UK Government’s biggest investment in 5G for manufacturing to date.

Key to the success of 5G-Encode’s use cases has been the deployment of network slicing and splicing technology developed by leading 5G-Encode consortium partner Zeetta Networks.

Within any manufacturing environment there are multiple tools and machines all requiring different levels of connectivity with varying degrees of latency and throughput. Slicing and splicing technology enables operators to create multiple virtual networks that can be customised according to specific services and traffic levels needed.

The network can therefore be optimised to meet the needs of different processes to improve efficiency, performance and business output.

The first phase of the industrial private network, using 4G, was used to establish a baseline for existing cellular technologies, against which results from the private 5G network can be benchmarked. The results of phase one will be revealed at a phase two launch event at the NCC in November 2021.

As part of the phase two network deployment, Zeetta and partners have created a new network slice by stitching together slices from one transport network and two separate private networks: one located at NCC HQ and the other at another facility at NCCI located several miles away from the first location.

Zeetta Networks CEO Vassilis Seferidis, said: “For the first time in the world, an industrial 5G network can not only be customised and divided into multiple logical networks, but each of those virtual networks can be extended across a transport network to reach another virtual network in a completely different administrative domain.

“Zeetta’s technology enables the ‘stitching’ of the individual network slices to create a new network slice through an easy-to-use-graphical user interface.

“This ‘end-to-end’ slice delivers continuous connectivity for the seamless delivery of applications across different network domains regardless of vendor or technology. This would allow, for example, a critical asset to be tracked continuously in real-time and with the same quality-of-service as it is transported from the point of production, to being received at the destination location.”

Based on open standards, the homegrown British software is compatible with O-RAN (Open Radio Access Networks) and other open networking technologies, making it both technology and vendor agnostic.

This directly supports the UK government’s 5G Supply Chain Diversification Strategy, which advocates deployment models based on open interfaces and interoperable standards for the Telecoms industry.