How SRAM turned to generative design and metals 3D printing to develop a concept bicycle crank arm to help develop faster workflows and inventive ideas for traditional manufacturing methods. Drew Turney reports

What’s the most important part of a bicycle? Unlike automated forms of transport, nothing on a bike is extraneous, and the device as a whole won’t work if you take away any parts.

But spare a thought for the crank arm, the length of material that connects a bike’s pedal to the front chain rings and converts the kinetic energy from pedalling into torque that rotates the chain.

It’s an ideal candidate to be improved using loadingled design tools and new production methods, which is why global bike part manufacturer SRAM implemented Autodesk Fusion 360 to help speed its iterative workflow for a new crank arm concept.

“I see a role for generative design in the very front end of structural components,” says SRAM senior design engineer Will King. “If we start looking at the design process very early, we can use it to better understand load cases and how we can accomplish the look consumers want in the final product.

In SRAM’s case, the required geometries needed to consider the amount of force a rider could apply to the pedal without the crank arm snapping (which depended very much on the material used), clearance from the bike frame, and clearance to the rider’s heel.

From there, likely candidates for the new form emerged that could be fed back into the system for further iterations, depending on how closely they met the minimum performance requirements—anything from how well it would work in digital simulations to adherence with relevant industry standards and regulations.

The leading design ideas were prototyped quickly using additive technologies and various materials, from polymers to aluminium or titanium, depending on the part’s requirements for real-world appraisal and testing.

The first metal crank-arm prototype was made using selective laser sintering (SLS) 3D printing at the MxD lab in Chicago.

SRAM then went to Dutch 3D printing experts Additive Industries, which produced the aluminium and titanium 3D-printed versions at its US facility in Los Angeles.

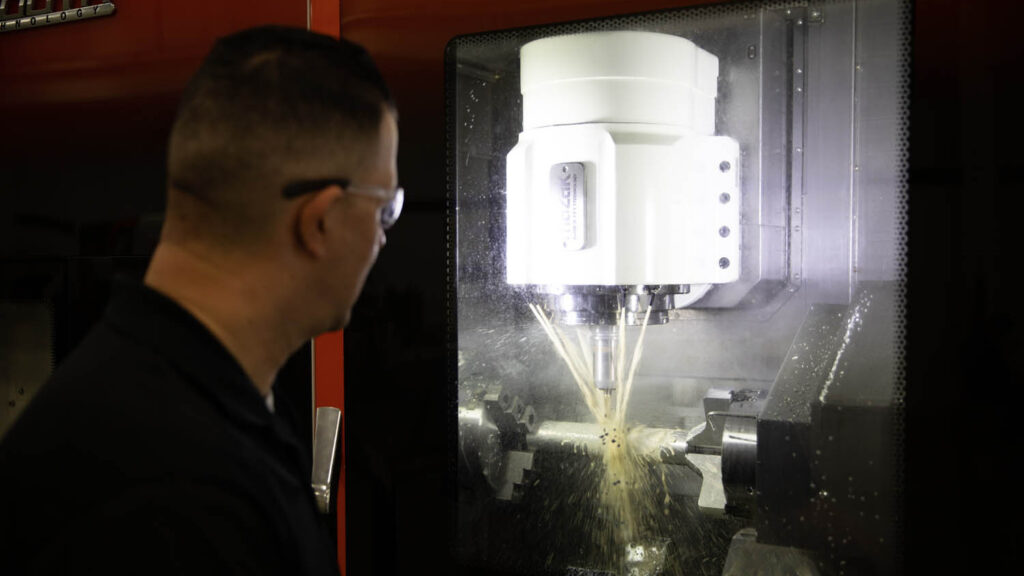

The aluminium prototype first proved the design; then, the 3D-printed titanium crank arms went through stress testing and on-bike testing. The team then moved on to a die-cast model, followed by 3- and 5-axis CNC prototyping by CNC machine manufacturer Mazak, which returned titanium crank arms to SRAM for final testing.

SRAM’s design team saved time and money by not prototyping every design candidate selected. Using cheaper and faster technologies such as additive early in the prototyping stage, after generative design had done its work, resulted in only one part to cast and evaluate. And that single part resulted from far more possible designs, much quicker than the designers could achieve through typical means.

Aesthetically the product is a world away from what SRAM, and anyone else for that matter, has produced before – something that might deter some designers initially.

“Sometimes, if it’s not directly related to what we do, it’s hard to see the advantage,” says Dhiraj Madura, the global director of industrial design from SRAM’s Chicago office.

“Whereas being an industrial designer, I have the ability to kind of see beyond the weird structure and use it in a way that helps us think differently.”

Madura continues: “It’s about reducing the friction between design and engineering. It’s about saying, ‘Okay, let’s throw this wild idea out there. If it works, it works. If it doesn’t, we’ll find out.’”

Using these technologies, the SRAM design team could produce a part that was twice as strong and 20% lighter, with the divisive nature of its styling likely to be outweighed by its sheer performance in an industry constantly striving for better power to weight ratios.

And while this crank arm project is unlikely to make it into full production, its impact on SRAM’s R&D efforts will be felt for a long time to come, potentially making it their most important part of a bicycle. sram.com

A version of this article originally appeared on Autodesk’s Redshift