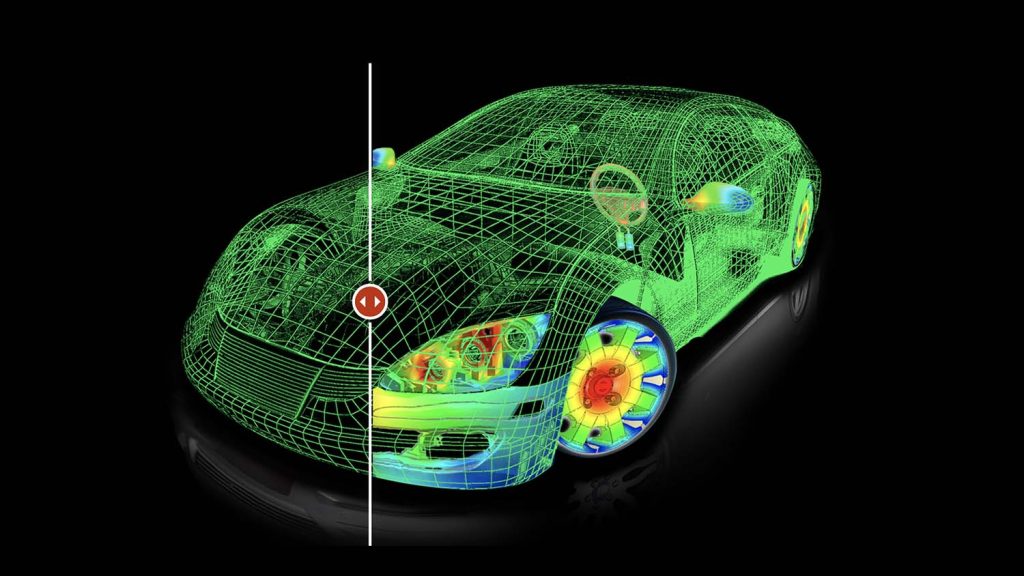

Core Tech System has announced the release of Moldex3D 2022, the latest version of its moulding analysis software series, developed to deliver more accurate moulding results for users.

The CAE simulation software provider said that the new update was introduced to reinforce analysis performance.

The new version should also provide new services to improve smart design, smart management and smart learning, achieving seamless design, production integration and team efficiency.

Moldex3D 2022 supports user-customised simulation results and report production, which should facilitate team communication and establish analysis standardisation.

Users should now be able to use the Design of Experiment (DOE) analysis wizard to identify key influencing factors and optimise product quality.

DOE and Shell analyses are supported on the Linux platform, which, Core Tech System said, can greatly reduce calculation cost, shorten the calculation time and speed up development.

Moldex3D Studio should also provide versatile API functions to help users build automated analysis, compare simulation results, optimise processes, and realise intelligent integration.

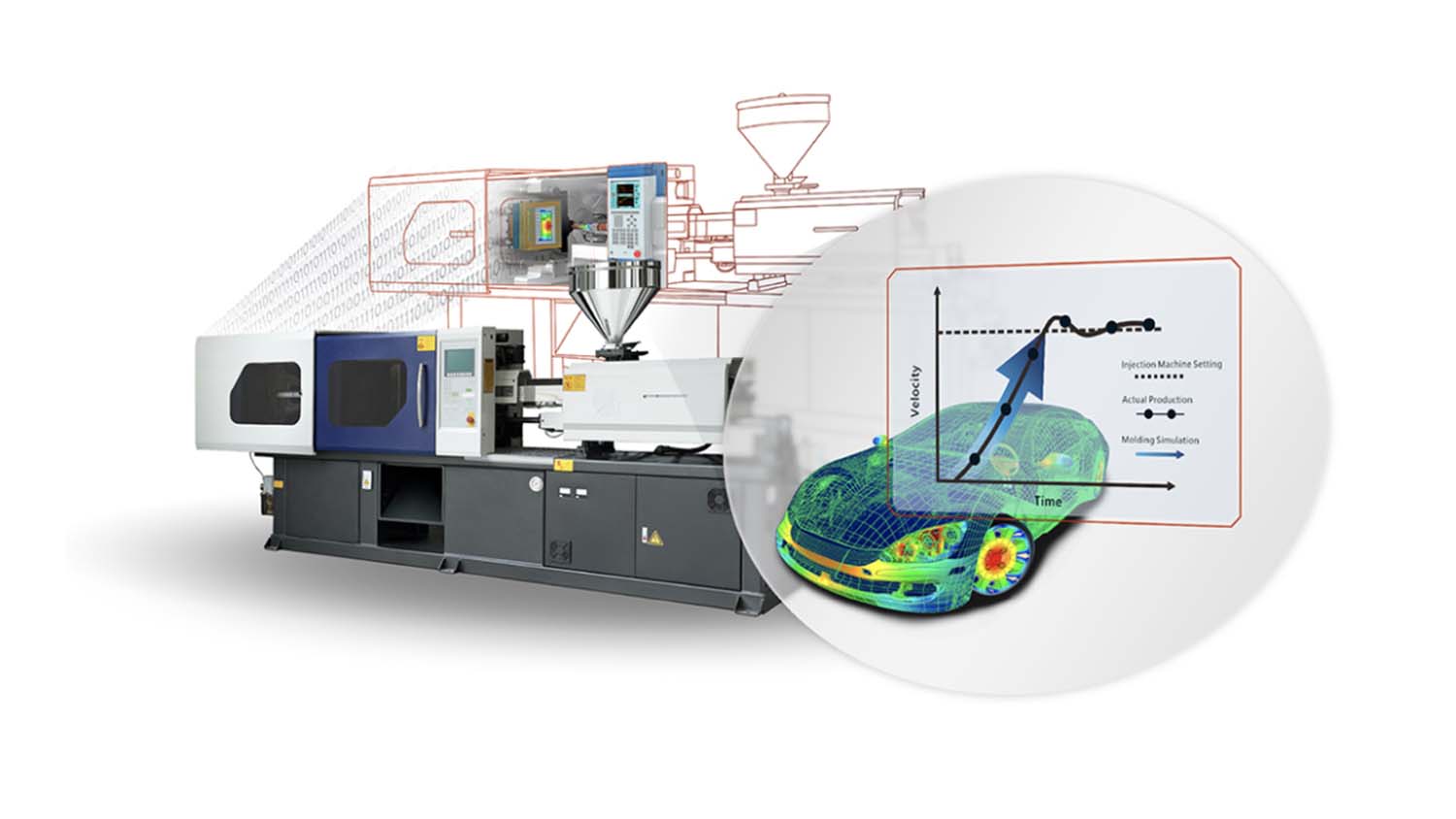

To help users control the two most critical factors in the moulding process, machine and material properties, Moldex3D developed the Machine Characterisation Service, to capture unique performances and dynamic responses from each moulding machine.

The service is also integrated into CAE analysis to reflect real manufacturing conditions and present more accurate simulation results.

Regarding material support, Moldex3D said, it has established a professional material measurement centre with ISO/IEC 17025 certification.

The centre contains decades of plastic data measurement technology and experiences, to construct complete material digital twins, improving prediction accuracy on injection pressure, warpage, and shrinkage.

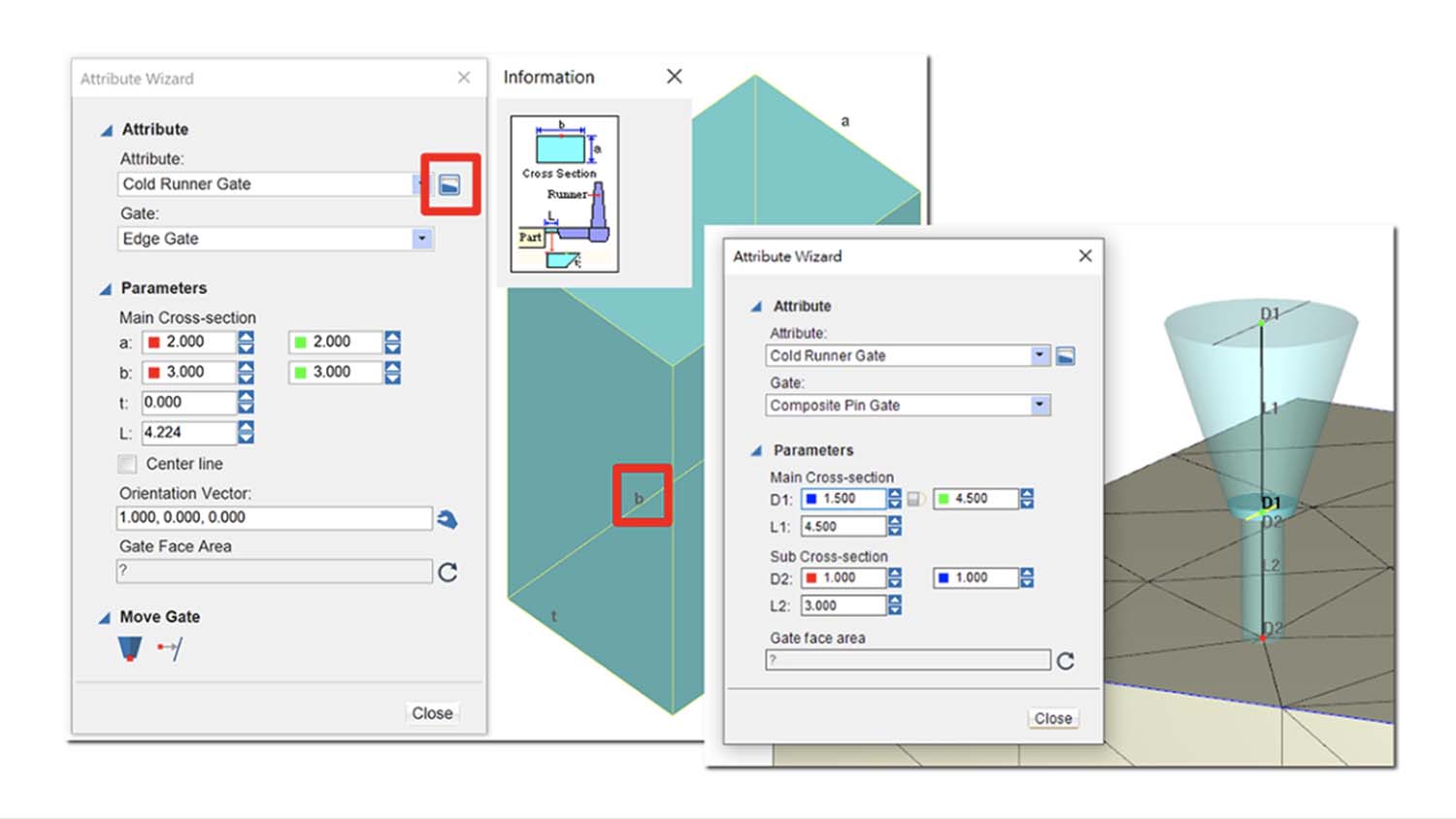

Moldex3D 2022 should also feature enhanced Runner, Gate, and Cooling wizards, which should strengthen the design of runners and cooling line systems, and provide more diverse layouts for different situations, making the design more flexible.

In terms of mesh, Moldex3D should optimise the quality and efficiency of mesh generation, enhancing preprocessing, CAD import, mesh functions and geometry healing functions, and allowing users to repair geometric defects more easily and improve model quality.

In IC packaging simulations, this update should have more powerful modelling capabilities for various processes, and provide a more complete IC Auto Mesh function, allowing users to freely create advanced packagings, such as CoWoS and InFO types.

Moldex3D iSLM should record the entire development process of design and mould trial, to allow users to better utilise the digital assets obtained from every mould tryout.

These data are uploaded to the cloud system, so multinational team members can access, share, and reuse simulation data anytime, anywhere, accelerating R&D innovation, and saving management costs and time.

Moldex3D has also launched the MPE digital learning system (Moldex3D Plastics E-Learning), which aims at teaching professional terminology in the plastic moulding industry, knowledge of injection moulding machines, and real cases collected from decades of industrial experiences, to users.