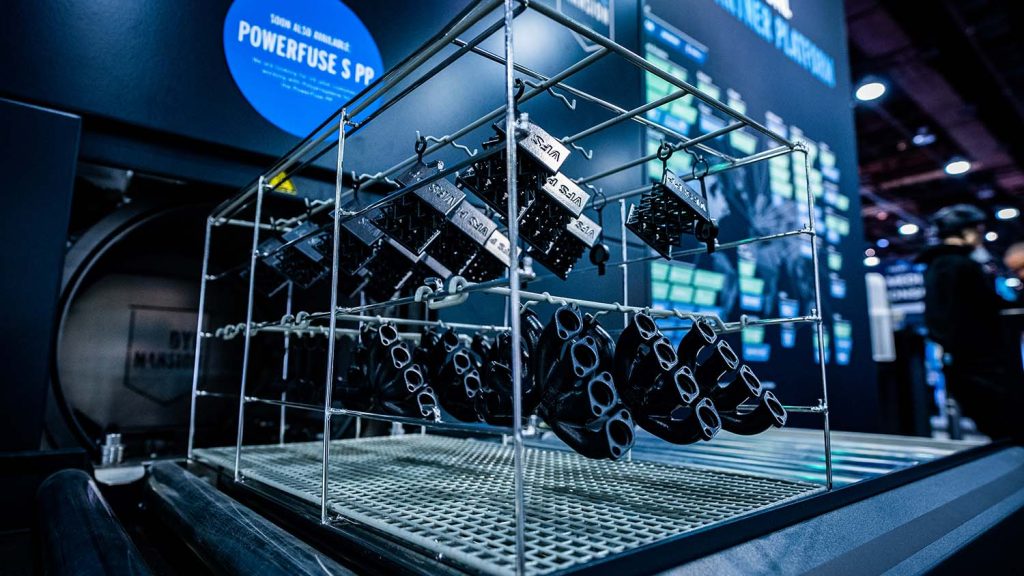

DyeMansion has showcased parts finished with its new Powerfuse S PP at Rapid + TCT, ahead of the official launch which will take place at Formnext 2022.

This new technology uses vapour polishing which should improve the mechanical properties of polypropylene parts, achieving sealed, washable surfaces that are suitable for industrial use.

“One of the biggest limitations in additive manufacturing is material availability. Enabling the industrial use of PP will be a big driver for further growth in our industry,” said the DyeMansion CEO Felix Ewald.

“We are very happy that we found a way to provide injection moulding like surfaces and enhanced properties through our Powerfuse S PP and we are very much looking forward to seeing the first high-volume use cases soon.”

DyeMansion said that the technical specifications of the new Powerfuse S PP are nearly identical to the current Powerfuse S version.

The German post-processing solutions company claimed that Powerfuse S PP is sustainable and biobased, and has already been successfully tested with all common PP materials on the market such as HP, BASF, EOS, ALM, Prodways, AM Polymers or Covestro.

DyeMansion has also announced the compatibility with Lubrizol’s Estane 3D TPU. This material features abrasion resistance and high mechanical properties which tend to complicate traditional vapour polishing.

DyeMansion said it has been able to develop a new program for its Powerfuse S system, specifically created for this TPU.

The process is available immediately and should reduce surface roughness to a minimum, sealing the surface of TPU parts and making them ready to use.

At Rapid, Dyemansion is also showcasing one of the first applications using this material, finished with the DyeMansion print-to-product workflow: the Quatro Prosthetic Sock from the Colorado-based medical tech company Quorum.