Kramski Group’s success story started in 1978 with the launch of Kramski GmbH in Pforzheim, Germany. Founded by Wiestaw Kramski, the company’s objective was to develop and manufacture innovative stamping and progressive die tools.

Just one year later, the company was selected as one of the award recipients in a contest recognizing the successes of newly established companies. The competition was conducted by the magazine, Capital, which honoured Kramski with 30,000 Deutsche Marks (the official currency of West Germany at the time) in prize money.

Much has changed since that time, except for Kramski’s continued success.

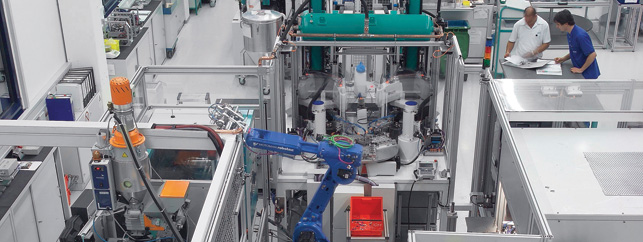

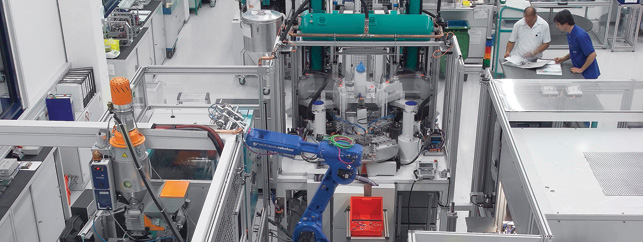

With a transformed business strategy in the 1990s, the company became a leading supplier of micro parts of metal and plastic. Kramski develops and manufactures most of its own high-speed, progressive die and mould tools and manufacturing systems for in-house part production. In fact, Kramski produces 100 percent of its tools, using 95 percent of the tools it produces in-house.

Globally positioned

A global company, Kramski has established development and manufacturing sites in Germany, India and the United States. The company delivers more than two billion parts like connectors, electrical contacts and switches to its customers around the world.

Automotive, electronics, telecommunications and medical technology represent its primary targets. Customers in these and other select industries benefit from the company’s extensive market experience and technology expertise, which ensure both high and consistent quality across its product lines. This includes professional golf putters designed and produced both in Germany and the United States by a separate business unit.

For all products designed and manufactured at the Kramski sites, high precision and productivity are imperative. The high productivity achieved by the company’s tools and manufacturing systems allow it to produce parts in Germany and sell them worldwide at competitive prices.

This also applies to all other sites. While the Florida-based US site produces goods mainly for US customers, Kramski’s main customer base is located in China. In addition, the Kramski Lanka Pvt. Ltd. in Sri Lanka delivers mould and die tools and composite parts to customers throughout Asia, Europe and North America.

Moreover, Kramski’s decentralised manufacturing strategy means excellent cost benefits for both the company and its customers.

Advanced technology

Converting innovative ideas into reality requires not only know-how and dedication of employees, but also the use of advanced technology.

In the case of a manufacturing company like Kramski, this includes productive and precise computer numerically controlled (CNC) machine tools for drilling, milling or electrical discharging, as well as sophisticated IT solutions to support and optimise design and manufacturing processes.

Kramski was an early pioneer of CAD and computer-aided manufacturing (CAM) software like many other manufacturing companies in the 1980s and 1990s. Management noted that this was a time that CAD/CAM systems generally promoted advantages greater than they could deliver, meaning that ultimately there were no true turnkey solutions available to handle all of the specific requirements of product development.

In 1995, Kramski deployed a 2D CAD system that was highly customised in order to address missing functionality and to automate time-consuming routine works.

Although this system was quite successful, over the years more and more barriers arose. For example, the missing functionality to define complex 3D surfaces made it difficult to reliably manufacture parts within consistent quality standards.

In addition, without an integrated software system for managing processes and product data, it was complicated for multiple designers to simultaneously work on the same tool, thus increasing the risk of data control and revision issues.

The move to PLM

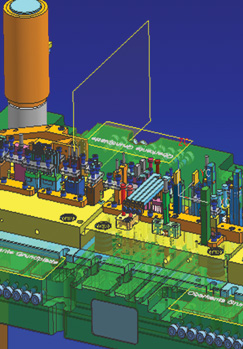

Due to the limitations arising with its customised system, in 2005, Kramski began deploying Product Lifecycle Management (PLM) technology from Siemens PLM Software. This included NX, in conjunction with the Product Data Management (PDM) system, Teamcenter.

Critical to the selection of NX was its broad-based functionality and overall flexibility, as well as its support of process-specific applications for the design of progressive die and mould tools, including Progressive Die Wizard, Mold Wizard, and Electrode Design. Especially important was the seamless integration between NX and Teamcenter.

Kramski deployed Teamcenter to improve concurrent engineering design processes and to manage product data and release status. This includes a clear control of release processes and access rights, automated bill of materials (BOM) creation, and workflow optimisation.

The company also wanted to provide designers, as well as manufacturing engineers, shop floor employees and other personnel with easy access to 3D model visualisation.

From a business perspective, the investment in NX and Teamcenter was explicitly aimed at improving productivity, shortening development and production cycle time, and improving the quality of processes and products.

Customisation for further automation

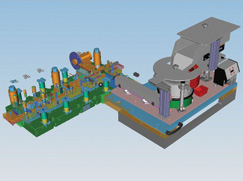

Considering the complexity of Kramksi’s progressive die tools, and with metal forming no longer being done with just stamping and bending of sheet metal anymore, Kramski employed an internal programming team to further extend the advantages of NX and Teamcenter.

In fact, producing the company’s tools most effectively is accomplished with modules for deep-drawing, laser welding and assembly functions. The intent of the customisation project was distinctly different than what the company implemented with its prior system, that being, to add functionality.

The customisation of NX was done to further automate routine work processes and shorten design time, including a streamlined approach to filling libraries with proprietary standard parts.

“The designers should concentrate on their design tasks and not be interrupted by routine work,” explains the system developer for NX and Teamcenter at Kramski.

“For example, part numbers, positioning information and other material master information are automatically assigned to parts and checked by the system, so that the data for the exchange with our ERP [Enterprise Resource Planning] system is correct.”

Concurrent engineering

Shortening the development cycle time for a new tool requires the capability for multiple designers to work simultaneously on the same project.

“Progressive dies consist of one assembly and multiple sub-assemblies for the different required steps,” notes the group leader of tool design at Kramski. “With Teamcenter, we now can control the access rights, which allow different designers to work in parallel on different subassemblies.

“Usually, a designer works on one particular subassembly at a time. Once the work reaches a specific status, another designer starts on the same module with detailing or drawing creation. Here again, Teamcenter controls the access rights.”

Increased transparency

The vision to replace technical drawings with 3D product models for visualisation has sparked a provocative debate within the manufacturing industry for years.

At Kramski, this point is regarded very pragmatically. The goal is not to achieve an absolutely paperless factory, but to simply reduce the number of drawings. The first step has been done with the move to 3D CAD and advanced PDM. Up-to-date 3D models of tools, manufacturing systems and end products are made accessible to all involved parties at any time.

This not only makes the complete product engineering process essentially transparent, it also reduces possible misconceptions and constant queries.

Improving quality

Across the board, the deployment of PLM has led to a measurable quality improvement of products and processes.

There are numerous examples of this success. Integrated, 3D surface-design functionality enables higher precision and consistently reproducible tooling parts. The prior system often required manual adjustment of areas with freeform surfaces.

According to the group leader, “With this functionality, we obtain a high degree of added value, and without 3D we couldn’t manufacture our parts at the required quality. In addition, we can flatten the 3D part to automatically produce and get the shape of the flat blank.

“Based on the blank, we can easily define the width of the sheet and the feed. This functionality was not available in the 2D system. Another plus is that the strip in 3D corresponds to the strip in the real tool. With this function, notches or recesses are not overlooked and an accurate design of the different stations is possible.”

There’s another advantage. The fine-tuning process, which is virtually always required to turn the theoretically exact end product into the real one, has been measurably simplified using NX.

Enter Teamcenter to further improve processes. “With Teamcenter, we always have a uniquely defined drawing for our tools,” notes the group leader. “With the defined workflow, the data is always up-to-date. With the combination of NX and Teamcenter, we always have a properly defined and up-to-date parts list for our tools. Our colleagues on the shop floor cannot access outdated or wrong data, and if an old drawing happens to be lying around, it is readily recognised.”

Teamcenter uses stored data to automatically generate a tooling sheet, which contains critical tool parameters. In addition, the bill of materials and other important process-related documents are generated.

Competitive edge

Teamcenter and NX have led to a more transparent and secure product engineering process, from concept design through manufacturing and assembly.

Designers are focused on their work and are now working in parallel and collaboratively. Improved visualisation capabilities have resulted in the clear communication of design intent.

Kramski’s products are being produced at a higher level of consistent quality. And Kramski continues to fervently identify areas for process advancement, including a focus on the ongoing process of part standardisation to achieve continuously shorter development cycle times and the automation of more workflows.

www.kramski.com

www.siemens.com/plm

Tool and part manufacturer Kramski has super-tuned its production with NX Teamcenter