Sandvik Coromant has announced its latest partnership with Siemens Digital Industries Software, to integrate its PrimeTurning technology into Siemens’ NX.

The partnership will allow NX users to efficiently define PrimeTurning operations through integration of the PrimeTurning module.

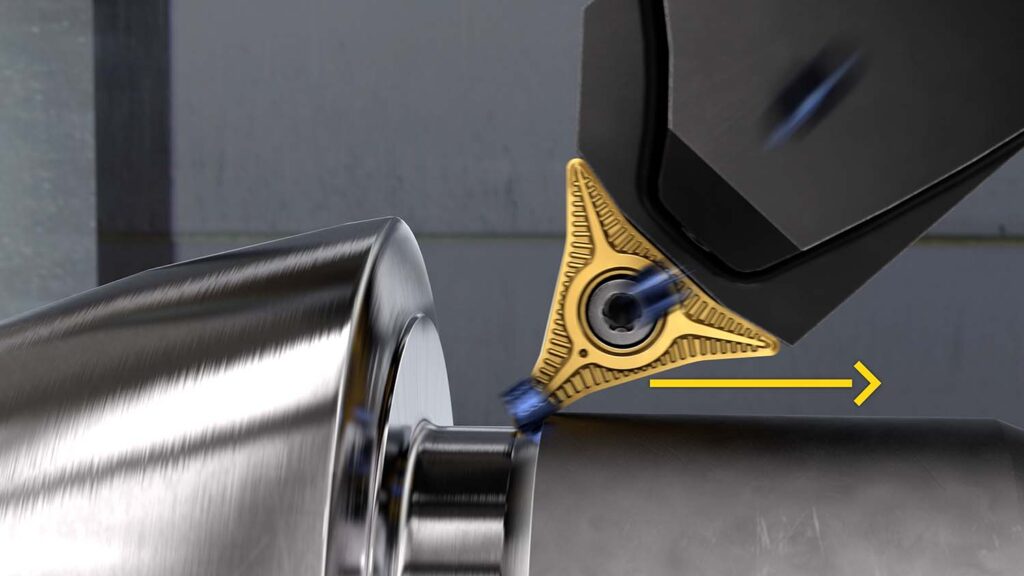

The PrimeTurning methodology is based on the tool entering the component at the chuck and removing material as it travels towards the end of the component, away from the chuck. This allows for the application of a small entering angle and the possibility of machining with higher cutting parameters. More conventional turning, from part-end to chuck, can be performed using the same tools.

Sandvik states that the deployment of PrimeTurning could see some applications gain productivity increases in excess of 50 per cent, compared to using conventional techniques.

The NX partnership is not the first time that Sandvik Coromant has collaborated with Siemens, with Sandvik Coromant saying that it is frequently using Siemens’ software and systems in its own production and product development.

“Siemens and Sandvik Coromant have a trusted, long standing relationship,” said Marko Stugbäck, product manager for digital machining business at Sandvik Coromant. “The integration of PrimeTurning into NX is another demonstration of the mutual understanding and support we have for each other, which also benefits the wider manufacturing community.

Stugbäck continued to explain that he sees the benefits of PrimeTurning ranging from turning flexibility in all directions, longer insert lifecycles, up to a 50 per cent productivity increase and faster return on investment, bringing down the overall cost per part. “This is all while making the programming of machining operations more efficient and easier to manage,” he said.

Cambrio CAM software acquired by Sandvik for ‘total manufacturing’ plan