Walking around last year’s TCT show, which was held at Coventry’s Ricoh arena during October, you were sure to come across some rather innovative rapid prototyping technologies.

Using SolidWorks 4D Products could easily find out how all the parts and components would fit inside the smaller dimensions of the SLM125 as opposed to the bigger SLM250

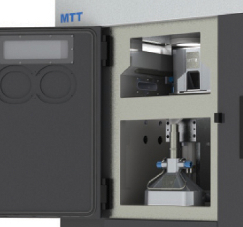

MTT Technologies Group, a Staffordshire-based company that specialises in the design and production of a range of additive manufacturing and rapid prototyping technologies, was exhibiting its range of Selective Laser Melting (SLM) machines including the SLM125 and SLM250.

This pioneering process is gaining increasing interest due to its ability to create highly complex and intricate metal parts. It uses a high powered laser to fuse fine metal powders together layer by layer direct from CAD data.

“SLM is gaining ground in medical, orthopaedic, dental, aerospace – in fact, lots of industries are starting to review it as a manufacturing technology due to its ability to create parts that can’t be replicated in any other way,” says Robin Weston, group marketing manager at MTT.

Previously the company had been selling another supplier’s SLM machines, however, when this relationship came to an end MTT realised that it was vital to keep the products in the range.

“We decided that, like all our other products, we would design and build our own SLM machines and market them as our own product,” says Weston.

As the larger machine, with its build range of 250 x 250 x 300 mm, was the more popular of the two machines and sold in higher numbers MTT decided to develop that one first using its in-house design resource. However, it soon realised that the smaller machine with its build area of 125 x 125 x 125mm would also need to be developed if it was to launch both machines at a forthcoming trade show.

“Once we had stopped selling the supplier’s machines we had a very short window to get our product line back in place and we didn’t have enough resources in-house to do both projects,” explains Weston. So, the company pulled in some additional design resources in the form of Cheshirebased product design consultancy, 4D Products.

Against the clock

4D initially assisted with some small elements in the design. “Once I had gained knowledge of the 250 system I received the brief to design the 125 machine, which was taking the SLM250 as a platform of technology but then stripping out as much cost and complexity as possible,” describes Iain McCall, 4D Products’ director.

It would still feature the same innovations as the 250 machine, including inert powder handling, safe change filter system and vacuum assisted inert atmosphere, but would be suitable for an office environment and would importantly be able to fit through a normal sized door.

“At the very start we were given a point in the diary that was just three months away. It was really short but we did it and we did it with enough time for it to get manufactured, put together and shipped to the trade show in Cologne,” comments McCall.

Although Weston realised that the design would be constrained by the technology that needed to be wrapped, he wanted the machine to be more than just a metal box.

“A lot of the previous versions of this technology were designed by engineers who were experimenting with how to make the fundamentals work so the usability aspects of the machines (such as cleanliness, safety and the way the operator interacts with the machine) were not well resolved.

So part of the brief that 4D was working to was to de-skill the process – to make it more intuitive and certainly safer so that you minimise the exposure to the powders. Essentially make the technology accessible,” describes Weston.

Sketch up

At the very start of the design process for the SLM125 project McCall sat with MTT’s R&D director and worked out how all the parts would fit within a smaller package.

“Within half an hour we had a biro sketch of how the machine might look with gas handling in this half and electronics in the other. Schematically we could draw it out between us very quickly,” recalls McCall.

Being such a mechanically complex machine he moved very quickly into the CAD environment in order to resolve all this fine detail.

He started with the known elements and using the supplier’s CAD files of the standard parts he built a CAD model of the machine around that.

“The PC is rack mounted so there were CAD models of that and the laser too so we had all these elements dropped in and almost arranged them in an assembly without anything around them. This was the starting point really,” he explains.

The 2D CAD system MTT had previously used ultimately led to frequent errors when building complex, large component machines.

Having seen McCall using SolidWorks to create models and witnessing how much easier it was to design in 3D, the company was spurred on to invest in two seats of SolidWorks. “4D Products was really instrumental in us getting 3D CAD in-house,” admits Weston.

McCall adds, “With MTT using SolidWorks during the project we could very easily create and swap data onsite and offsite as well as constantly keeping track of reviews.”

Taking advantage

Although the SLM125 was always going to be a sheet metal box, McCall wanted to design it as an enclosed system that was as well laid out as possible and straightforward to use.

“It was ‘more designed’ if you like within the constraints of where it was going to be used – it’s an industrial machine at the end of the day but it started to look like a whole system rather than a collection of machined parts,” he explains.

4D also took advantage of the nature of MTT’s business and its low volume manufacturing skills and made full use of its in-house rapid prototyping facilities during the development process.

“They were able to make an SLA model using our machines and then all those who have an influence on the product (like myself) can physically handle something and decide whether it was the right approach for what was needed.

That is a unique aspect of this business – we essentially use the products that we make for everybody else,” comments Weston. So, three months later, on time and on budget, the prototype of the SLM125 was ready for the trade show.

Although the market has been tough Weston is pleased with the investment it made in 4D’s design service and has in fact now noticed an acceleration in interest in both machines and is getting some serious enquiries.

Big to small

For 4D Products, MTT’s SLM system is just one of the many types of projects that the design consultancy gets involved with.

Having set up the company in 2008 McCall and fellow director and co-founder James Bell set out to offer a product development service for various industries.

“All our projects offer different challenges. The SLM125 project consisted of several hundred components and a fairly spacious product envelope.

Recent medical diagnostic products we’ve designed are much smaller – sometimes only two components that must meet strict criteria such as functional requirements, ergonomics requirements as well as strict cost points to be viable,” explains Bell.

“No matter what the brief we take a staged approach to understand very clearly the requirements and scope to operate within and then look to deliver the most effective, attractive and innovative solution possible.”

For a small consultancy it also gets a great deal of return business and has managed to retain all previous clients. For instance, it created a very successful urine screening test device called Uri-Plus for the Mast Group, a UK manufacturer and supplier of diagnostic products for clinical, industrial and veterinary testing.

The product was recently short-listed in both the Innovation in Diagnostics Project and Healthcare Project of the Year categories in the Northwest BioNow Awards.

On the back of its success, Mast is now working with 4D on the design and development of a disposable widget for MRSA screening. So it’s obvious that companies like Mast are seeing a return on the investment they make in design and also appreciate the personal service that 4D offers.

“The products we have done for MTT, Mast as well as our other clients, can be generating revenue for the next five to ten years based on an investment in a small period of time it takes to develop the product,” says McCall.

Helping hands

While Bell and McCall are actively involved in delivering every project, they will employ experienced staff and specialist sub contractors to assist in delivering specific projects, allowing them to be flexible and relevant in the services they offer.

“With the current economic climate we feel that the best way for 4D to remain competitive and sustainable is to offer a core service that is as applicable to as many businesses as possible,” says Bell. “We don’t seem to have any problems demonstrating our broad range of capabilities and then filling the gaps as and when required.

In the past we have brought in specific skills in stress analysis, specific mechanical engineering, electrical engineering, industrial design and 3D animation skills.”

In fact, with the SLM125 project McCall drew on the expertise of a mechanical engineer who worked with him on delivering the project.

In addition to the broad range of consultancy projects, 4D has also recently launched its own branded product called Snapswall, an innovative photo display system.

It was launched on the internet during November and as well as being accepted into three stores in the North West of England, it will now be sold by major high street photo retailer Jessops.

www.mtt-group.com

www.4dproducts.co.uk

www.snapswall.com

Design company 4D products brings success to manufacturer MTT Technologies