Sandvik has released Cimatron 2024, adding more efficient workflows and adding stronger core capabilities while incorporating new technology through collaboration with Sandvik Coromant.

Discussing the new release, Cimatron VP Antonio Parisse, said: “There is a good balance between product innovation and customer-driven enhancements. Leveraging Sandvik’s cutting knowledge and expertise is a prime benefit to our customers and enables them to deliver higher quality tools faster, easier and more efficiently than ever before.”

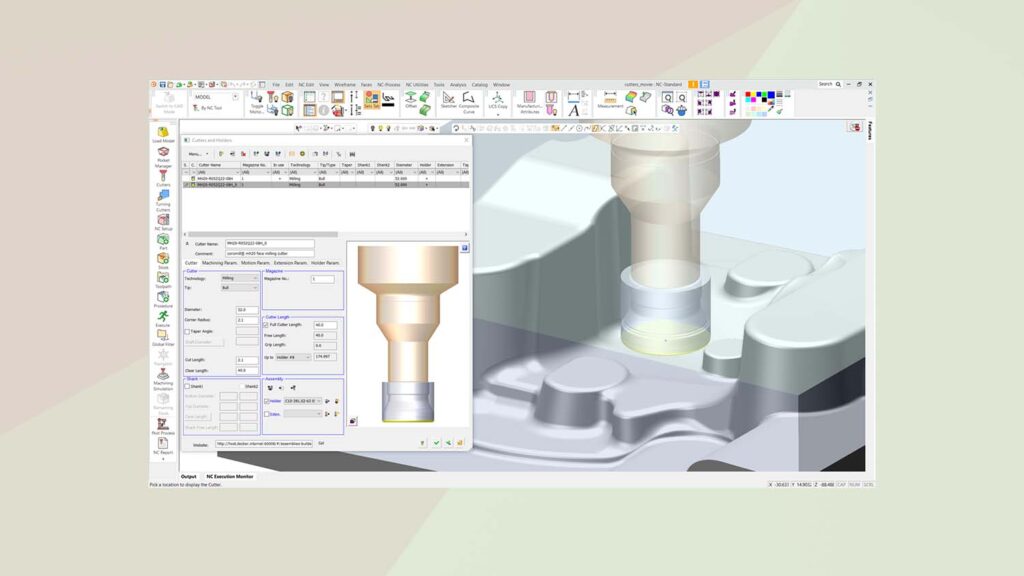

Cimatron say that the new release places a ‘strong emphasis on digital connectivity’, and in this instance is establishes direct integration with the Sandvik Coromant CoroPlus Tool Library and TDM tool management system, much like sister company Mastercam’s most recent announcement. By leveraging the CoroPlus Tool Library, users gain access to a collection of over 900,000 cutting tool items, with the system making intelligent tool recommendations based on material, operation, and tool type.

Workflow updates include multi-view spacing, batch-processing for drawing updates, tangent control for blending faces, and an option for easier capping of internal islands.

There are new features for 2D drafting, such as importing PDFs as real geometry and text, new minimum distance dimensioning, enhanced symbols, and improved geometric datum and tolerancing.

Cimatron 2024 also introduces a cleaner UI for controlling drafting standards, improved draft analysis visualisation, and automated chain selection of chamfer faces.

Mold makers gain CAD enhancements for rib construction with added functionality for working on multiple curves in a single operation and automatically extending rib geometry to part side walls. In addition, Cimatron 2024 can now create partial ribs in complex scenarios where a complete rib cannot be produced. Within mold design, the construction of 3D runners has been improved, providing better design control based upon constant volume, vertical orientation or section orientation.

Electrode design is a critical aspect of the mold production process. Version 2024 includes automation for the Burn Body operation to optimise the electrode body shape, control of electrode extensions, and non-cutting rules for manual construction.

Die designers can now easier build 3D drawbead geometry to control material flow during the drawing operation in order to achieve the optimal forming of a part without cracks and wrinkles. Cimatron say that the new routine will generate the drawbead based upon section type and automatically blend the result into the binder faces.

Elsewhere, support CAM operations, from basic 2D up to complex 5-axis, have been bolstered. The Enhanced Automatic Feed Control (AFC) routine has been completely redeveloped and optimises stock removal for roughing operations by automatically controlling the feed rate, resulting in smoother motion, faster machining times, longer tool life and fewer changes on the machine spindle and axes.

A new option for pre-drilling during roughing operations prevents cutters from plunging into blind pockets. Cimatron will automatically define the optimum position and depth for pre-drilling as part of the roughing procedure.

Cimatron 2024 introduces a new 3-axis deburring procedure to create chamfers or fillet shapes along sharp edges. CAM users can generate constant width or constant depth chamfers, as well as constant width or constant radius fillets.

For 5-axis machining, the software now allows the automatic use of remaining stock from previous 3-axis operations during roughing. This enables the use of shorter cutters for greater stability. Furthermore, the 5-axis auto tilting feature has been significantly enhanced with calculation time improvements of up to 25 times in some cases. This significant boost in efficiency enhances productivity and reduces overall machining time.