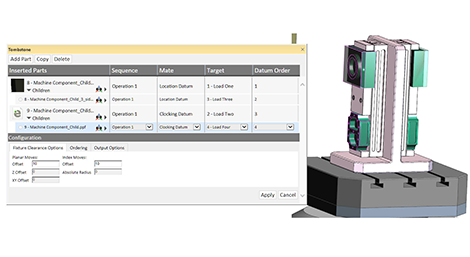

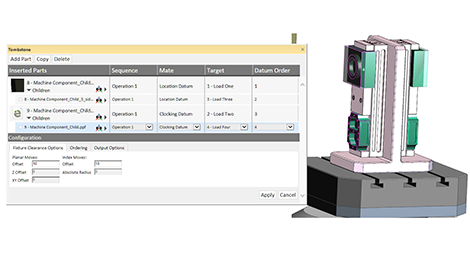

The new 2017 release of Edgecam introduces a Tombstone module for assembling pre-existing parts on a defined mounting device

The latest version of Vero Edgecam brings just under 50 items of new and enhanced functionality, covering turning, milling, wire EDM, machine configurations, and user experience.

Amongst the big new features is probably one of the simplest – a dialog window that enables users to add pre-machined part files, specifying the positions they are to be mounted on a tombstone or other multi-component work-holding device.

Once they are assembled, Edgecam automatically merges and rationalises all the machining sequences by tool or index position and optimises the NC output into sub-routines.

Elsewhere Edgecam’s Code Wizard includes two significant enhancements in terms of machine tool configurations for lathes. When specifying turret type, the code wizard now supports Linear configuration.

On this type of turret tools are mounted in a linear fashion, across either the X, Y or Z axis, largely for use on Swiss-type machines, while radially and axial mounted tools are also supported, in both single and multiple spindle environments.

Another new feature is a sliding spindle or material, providing support for machines where the tool is static but the material slides in and out of the chuck or collet.

Having supported probing on mills in previous releases, Edgecam 2017 introduces the same technology in the turning and mill-turn environment.

Renishaw and m & h probing systems are supported, as well as a new Probe category in the toolstore. Users can choose from a list of seven command cycles, all fully supported in the machine simulator.

Numerous new features have also been added to the workflow and planning board automated machining commands, leading to toolpaths being generated faster.

Strategies are now applied to both main and sub spindles in the turning environment, instead of only in main, meaning the strategies now support the Spindle Set-Up command by transferring the workpiece from the main to the sub spindle.

The introduction of hole finish method in the options dialog now allows reaming to be specified as a method of finishing a hole feature by checking the hole’s finish attribute.

A new use current tool check-box in the machine feature option can force the strategy to use the current turning tool or milling cutter.