Engineering nonlinear and multi physics simulation software Marc 2016 gets some of the biggest updates from MSC

MSC Software has announced new releases of some of its key simulation and analysis software for the coming year, launching Marc 2016, Nastran 2017 and Patran 2017.

Marc is used by product manufacturers for nonlinear and multiphysics simulations of engineered products, ranging from automotive rubber components to aerospace composite modelling.

The 2016 version introduces multiple material modeling capabilities, enhanced data fitting for material characterisation, and brings additional user productivity enhancements to Marc.

MSC Nastran 2017 expands its Nastran Embedded Fatigue capabilities to support vibration fatigue, and delivers faster dynamic analysis performance.

Patron 2017, meanwhile, benefits from a redesigned user interface to provide a common look for both Windows and Linux with improved graphics.

Other key new features below:

Nastran 2017

Vibration Fatigue

The embedded fatigue analysis capabilities have been extended to perform fatigue analysis in the frequency domain with random vibrations and deterministic vibration loads.

Acoustics

A capability called Peakout has been introduced to calculate the acoustic participation factors at the peaks of the frequency response.

The Non Parametric Variability Method allows the user to efficiently run a probabilistic Monte-Carlo simulation in SOL 111 and handle model uncertainties in the mid-frequency interval (300Hz – 1500Hz).

Rotordynamics

Rotordynamic performance is critical for safety and long life of jet engines. Enhancements in this release address performance and improved accuracy for 2D and 3D analyses.

Structural damping is incorporated for complex eigenvalue analysis and complex frequency response analysis of 2D and 3D rotors.

Mass and speed correction terms that account for inertial and gyroscopic effects of unbalanced mass can also be incorporated in transient analysis.

It is now also possible to perform modal complex eigenvalue analysis and complex frequency response analysis for rotors defined using axisymmetric harmonic elements and solid/shell elements.

Performance of Dynamic Analysis

The parallel modal analysis method technique of ACMS now supports the creation of external superelements, which are widely used to analyse large and full-vehicle models in automotive and aerospace industries.

With a 20-30% reduction in memory requirements for solid element models, ACMS enables users solve larger models with the available system resources.

DMP support has been added to the fluid eigen problem whereby the frequency range is subdivided and the work is shared by multiple processes. This can reduce the time to find the fluid modes by a factor of

2-4 depending on the frequency range and problem size.

Optimisation

Topology optimisation capability now supports stress constraints, which leads to more efficient mass minimisation while meeting the allowable stress levels. Design of components like brackets and engine mounts is made more efficient with this capability.

Advanced Nonlinear

Creep behavior of solder material used extensively in IC packaging, can now be more accurately simulated with Anand creep model.

Cohesive contact introduces a flexible ‘glued’ contact used extensively to model structures that are connected with fasteners like rivets, bolts, spot weld, seam welds, and adhesives. This new capability adds the desired flexibility to contact stiffness overcoming the stiff nature of glue contact, while at the same time avoiding costly modeling of discrete connectors.

Results

The new results database based on HDF5 standard that was introduced in the previous release is extended to support additional outputs including complex eigen value summary table, composite element output in linear solution sequence, bi/multi axial fatigue data, coordinate system transformation matrix, acoustic pressure and velocity data, and intermediate output at requested steps during MSC Nastran run.

Patran 2017

Patran is being released with a newly designed interface, while still maintaining its familiar look and feel.

– Common user interface on both Windows & Linux

– New framework design with improved graphics

– Improved docking/undocking features for the windows in Patran

– Enhanced & interactive spreadsheet widget

– Improved XY plotting feature

– Support for MSC Nastran’s new HDF5 result format

– Support for pre and post processing of MSC Nastran Embedded Vibration Fatigue

Marc 2016

New Material Models for Manufacturing Simulations

Understanding phase transformation of materials helps to optimize the manufacturing processes such as welding, casting, forging and heat treatment. Manufacturing engineers can use Marc 2016 to model as many as 5 phases, and predict material hardness, strength, residual stress distribution and final distortion.

Five new methods are introduced to define the flow stress as a function of the equivalent plastic strain, strain rate, temperature, and user-defined parameters. This provides added flexibility in the choice of plasticity models, especially for manufacturing process simulations.

Johnson-Cook damage model is frequently used in the engineering community to model damage progression in metals at elevated temperatures and high strain rates. This model, available in this release, can also be used to predict tearing or fracture of metal during operations like riveting process.

New Material Data Fitting Capabilities to Characterize Advanced Elastomers

Characterisation of materials requires derivation of specific parameters from test data, which can be a cumbersome task for complex models.

Marc 2016 introduces data fitting capabilities for recently introduced elastomer models, including Bergstrom-Boyce, Payne, and thermorheologically simple viscoelastic materials. Engineers from the automotive, aerospace, machinery, and oil and gas industries, working on elastomers will save time and effort coupling test data with analysis.

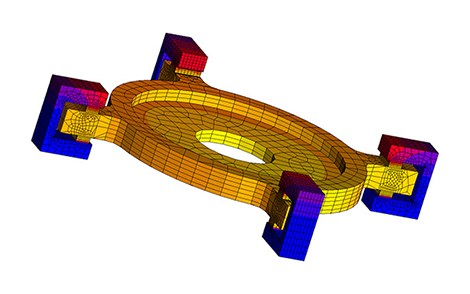

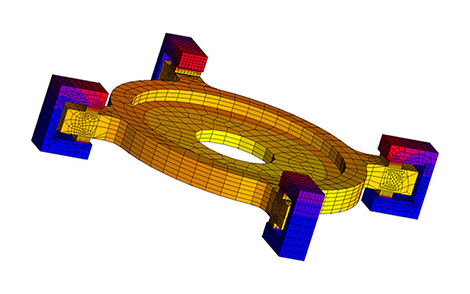

Contact Enhancements for Better Accuracy and Performance

While the contact set up has always been easy to use with Marc, contact results with the traditional node-to-segment approach depends on the body ordering.

A new capability is introduced in segment-to-segment contact method to overcome this limitation which helps users set up and solve complex contact problems faster.

The parallel processing technology has also been enhanced to support the segment-to-segment contact method enabling users to run contact analyses twice as fast using a 4-core system, which improves their productivity.