doling channels in the hot forming processThe latest release will allow for simulation of c

AutoFormplus has announced its latest R7 release will offer advances in process modeling for hot forming, while allowing users to take cooling channels into account.

The software, focussed on sheet metal process simulation for the automotive market, will allow users to benefit from higher flexibility and efficiency in process set-up and final validation for all forming processes in general and in particular for progressive dies and hot forming.

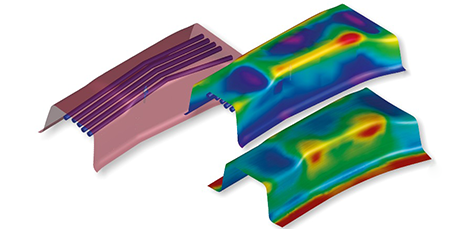

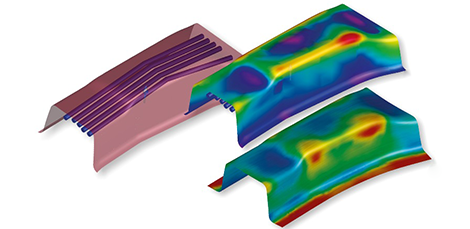

Cooling channels can now be easily modeled with 3D curves and their corresponding diameters. While different cooling channel layouts leading to different temperature distributions on the tool surfaces, hot spots on the tool surface can be detected and controlled via R7 depending on the selected layout of the cooling channels.

A highlight of AutoFormplus R7 is its improved planning and simulation for progressive dies, allowing for the import of CAD designed tool geometry for the final process validation; part import for the planning stage and part import for full process engineering, which includes die face generation and simulation.

In addition the software enables users to benefit from AutoForm-Sigmaplus capabilities as all Sigma pre and post processing functionalities are now integrated within AutoForm-ProcessExplorerplus.