If you’ve ever done anything with an STL file, chances are you’ve come across NetFabb, a German company that has long since specialised in doing interesting things relating to tessellated data and 3D printing.

Well, it seems that Autodesk is in the final stages of acquiring the company and its assets.

With Autodesk’s obsession with 3D printing at the moment, this is the most recent in a long line of acquisitions in the 3D printing space and it looks like the company is building up a pretty decent stack of technology that could prove interesting.

Netfabb is perhaps best known in the wider market for providing a free to use system to help with fixing STLs, but thinking this is what this acquisition is about would be wrong.

But why? Let’s explore exactly that.

3D printing isn’t a straight forward process. I’m not talking about sitting in a shed with a filament machine, I’m talking about the advanced, industrial scale end of things. There’s all manner of pre-processing that’s required to run any of today’s machines to their most efficient – and this centres on a couple of key tasks.

Data repair: STLs are tricky bastards at the best of times. You want to make sure the data is solid, watertight and scaled correctly.

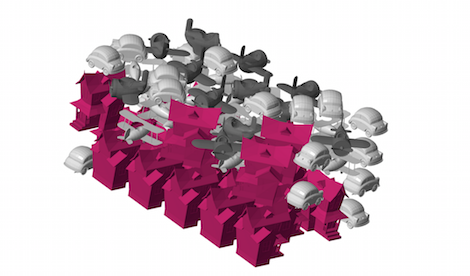

Packing: This is something that is perhaps restricted to power-based systems and it relates to ensure that you’ve got as many parts as possible in your build chamber. There are specific limitations for each type of machine and each material, much of which relates to the ideal zone in that build chamber that helps elevate thermal issues that can cause deformities in the parts at the periphery.

https://youtube.com/watch?v=2Uzx9BZlGQg%3Frel%3D0%26showinfo%3D0

Support generation: This is key for a lot of the SLA and metals based processes to help over come some of the thermal and structural (often a heady combination of both) associated with them.

Complex forms: This is going to be a big one in the coming years as additive manufacturing gets truly rolling. The potential to use unique and highly complex structures that couldn’t easily be manufactured any other way, is there. Generating those forms is a challenge – whether you’re stripping back material for light weighting or generating complex lattice work to help implants fuse with bones.

Process control: Whether you’re a bureau or a company pushing it hard, 3D printing is a manufacturing method and one that, when used in large scale, needs some form of management.

Take all of those and you’ll find what NetFabb has in its armoury. It’s got the packaging and support generation, its got tools for complex shape description and it has the process control tools as well.

What’s interesting is that despite all of the hype and the ridiculous amounts of cash thrown at the 3D printing market in the last three years, no-one has really developed much in the way of the software end of those – not the fancy headline grabbing software, but the nuts and bolts of it for those that actually have to do the work.

One organisation that’s always been strong in this field is Materialise and its Magics range of products. Its supplied with a lot of the higher-end machine and it has become the defacto standard for many. The one other alternative has always been NetFabb’s professional systems.

Now Autodesk has this, combined with the lessons it is learning in the 3D print world, other acquisitions (within Labs for one), it looks like the company is building up a set of tools that could rival what Materialise has to offer.