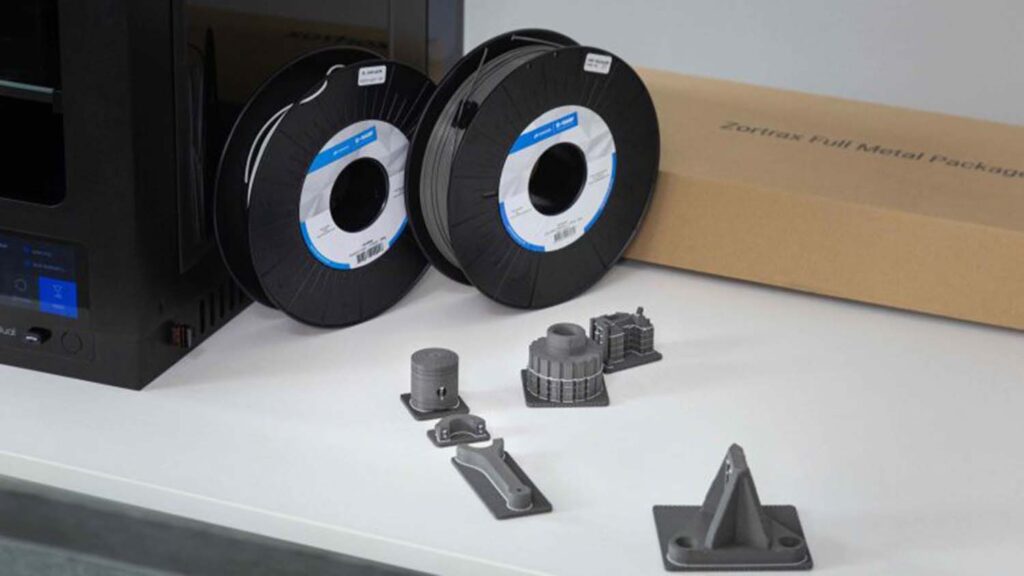

Zortrax has introduced new metal 3D printing options for its desktop M300 Dual 3D printer: Full Metal Package 316L and Zortrax Full Metal Package 17-4 PH.

The company said both solutions include all the essentials for desktop metal 3D printing thanks to metal-polymer filaments provided by BASF Forward AM: BASF Ultrafuse 316L and BASF Ultrafuse 17-4.

The M300 Dual which already had compatibility with a wide range of materials, now expands its capabilities with the Zortrax Full Metal Package 316L and Zortrax Full Metal Package 17-4 PH.

The solutions should come with Basf Ultrafuse Support Layer, dedicated support material for maintaining the desired geometry during printing and post-processing stages; Magigoo Pro Metal adhesive for reliable adhesion and easy part removal; an extra hot-end module for the M300 Dual printer; an adapter with a PTFE tube; and a voucher for professional post-processing services with Elnik, a trusted partner of BASF in Germany, which handles sintering and debinding processes to achieve steel-like properties in the 3D printed parts.

Alongside the introduction of the metal printing option, Zortrax said it has made several improvements to its Z-Suite slicer software in the Beta version 3.2.0.

These updates aim to cater to the needs of the user base and the specific requirements of post-processing steps involved in turning green parts into steel.

“The latest version of Z-suite Beta features a set of improvements in printing with metallic powder filaments. A new gyroid infill enables printing metal models with 60% to 90% infill,” said Zortrax R&D software project manager Ewa Piórkowska.

“Another change enhances the way in which support structures are printed with BASF Ultrafuse Support Layer. Here, supports are divided into smaller blocks along all axes and narrowed down towards the bottom. All this makes supports placed in the areas that are difficult to reach easier to remove and reduces their footprint on the model.”