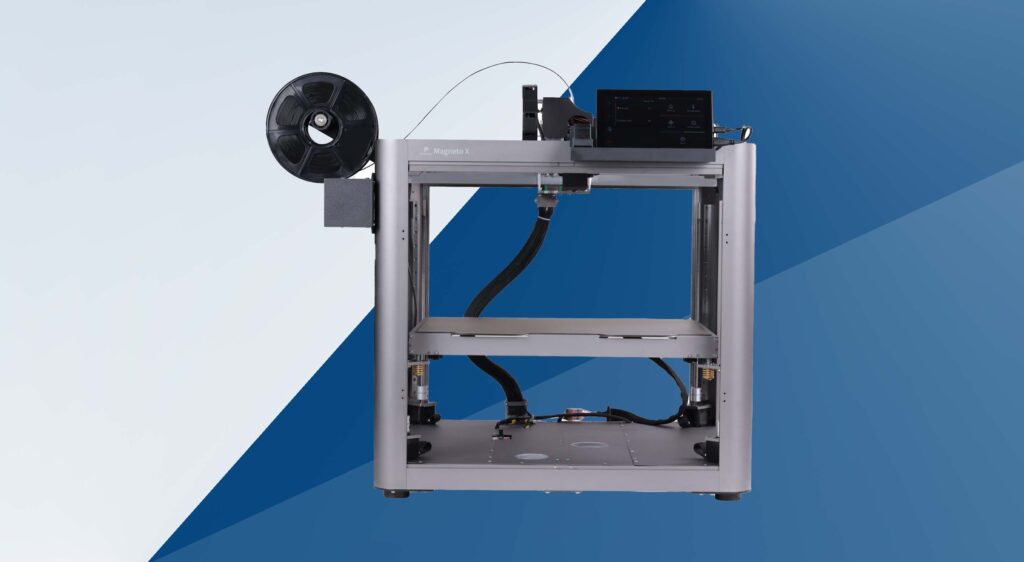

A proprietary magnetic levitation (MagLev) linear motor system for the X and Y axis, forms the unique feature of the Peopoly Magneto X desktop FDM 3D Printer.

By doing away with belts and pulleys, Peopoly states that its MagLev technology eliminates common artifacts like ringing and VFA (vertical fine artifacts), achieving repeatability of 3 microns

In contrast to traditional stepper motors, which can suffer from reduced precision under heavy loads, the MagXY system remains cool, sustaining its accuracy through a true closed-loop system with position feedback, while requiring less maintenance than traditional FDM belt and motor machines.

The 400 x 300 x 300 mm build volume 3D printer is equipped with a 300°C hotend and includes 0.4mm copper and hardened steel nozzles, making it compatible with a variety of materials such as PLA, PETG, ABS, ASA, and Nylon-Carbon Fibre.

The extruder also features a load cell sensor and a filament runout sensor. Initially, the load cell sensor calibrates the four independently driven Z-axis rods to level the build plate. Following this, the extruder performs a 48-point mesh measurement on the heated build plate, capturing detailed data for calibration.

Peopoly says that the Magneto X then uses this mesh data to set the Z-offset, ensuring precise auto-leveling. The filament sensor continuously monitors material levels to prevent print failures due to material depletion.

An aluminium build plate and support for 110V/220V power supply inputs round off the hardware.

The desktop unit supports Orca Slicer, PrusaSlicer, and Cura and provides multiple connection options such as WiFi, Ethernet, and SD card offline mode.

The US retail price of $1,999 includes a one-year parts warranty from Peopoly, with shipping beginning this November.