Mantle has announced the release of its new material, 420 Stainless Steel, a chemical equivalent to traditional stainless steel for 3D printing steel tooling.

This material addition improves speed in the manufacturing process while reducing labour requirements and is especially useful in industries that require corrosion-resistant tooling, such as the medical industry.

Use of 420 Stainless Steel allows manufacturers to produce production-grade tooling during the prototyping and product development process, meaning that the overall time of producing steel tooling for variation part moulding is reduced significantly.

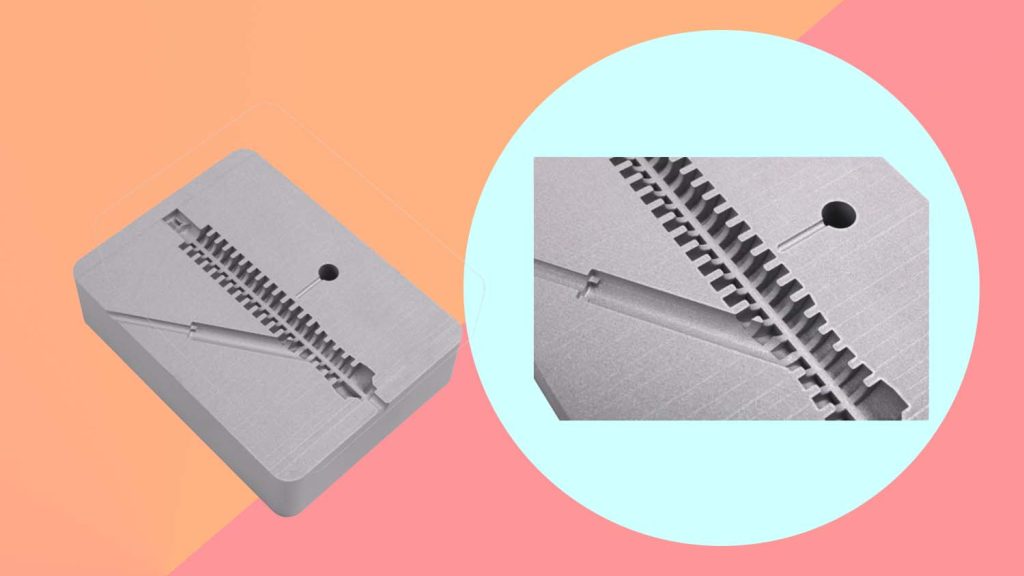

It is intended to be most beneficial for tooling applications that use conformal cooling channels.

These channels can only be created by using additive manufacturing and enable more efficient cooling than traditional methods, improving moulding performance and reducing cycle times.

Mantle’s 420 Stainless Steel’s corrosion resistance eliminates concerns of conformal cooling channels clogging due to rust.

It is the next material in Mantle’s family of Flowable Metal Pastes, which are all designed with accuracy and surface finish in mind.

420 Stainless Steel will be available to customers in the second half of 2024, and no hardware modifications will be necessary to use it with Mantle’s 3D printers.

It requires no modifications to toolmaking workflows for secondary manufacturing operations such as texturing, polishing, welding and machining.

Chief executive officer Ted Sorom said: “By combining the speed and cost reductions enabled by Mantle’s tooling-focused precision system with 420 Stainless Steel, we help our customers set a new standard for the speed of their product development.”