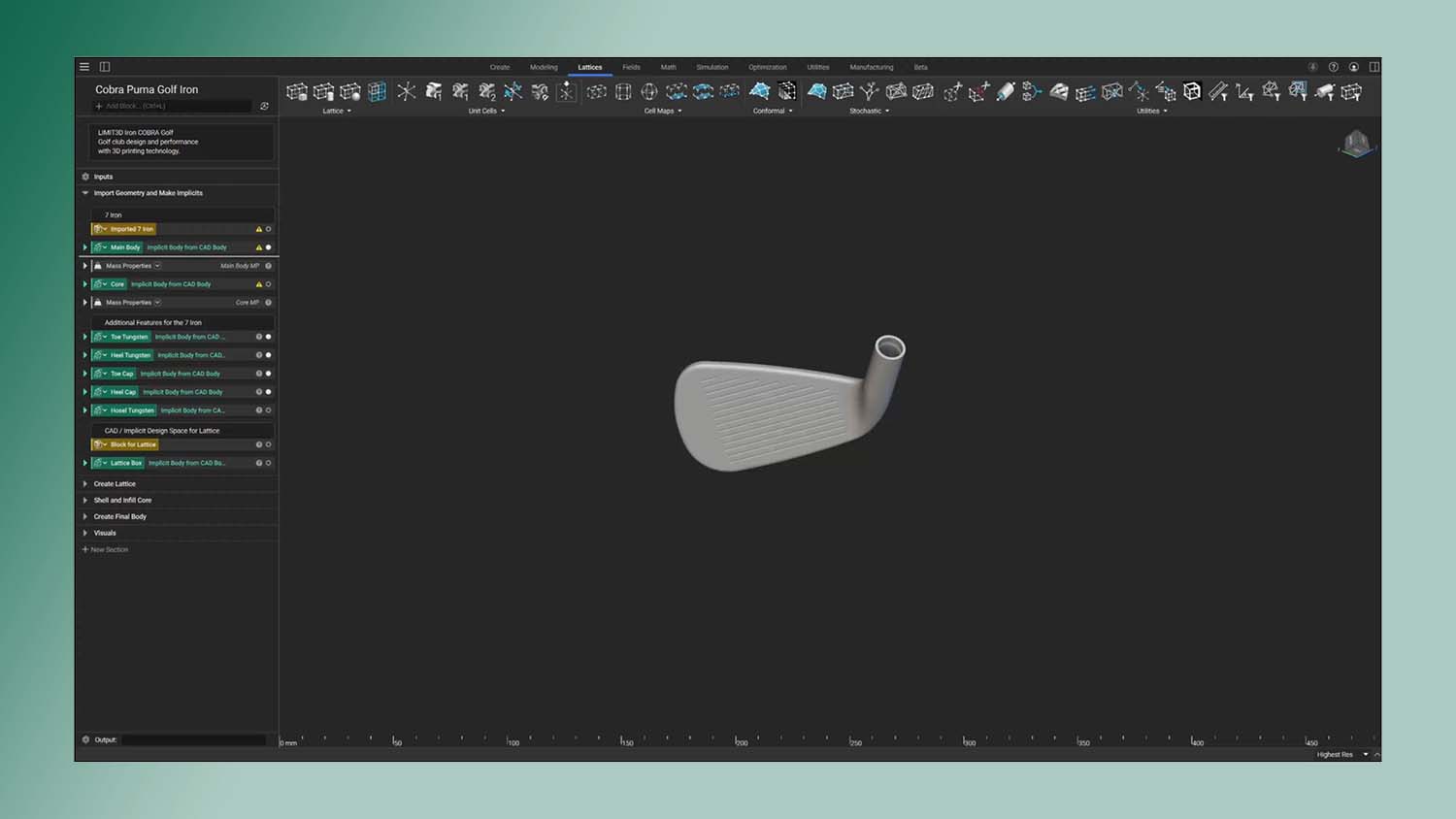

Cobra Golf has unveiled its new Limit3D irons, the first set of commercially available 3D printed steel irons that leverage its partnership with nTop.

With an ambitious goal to combine multiple factors into the single club – a compact player’s blade profile that offers a similar level of forgiveness as an oversized, game-improvement club with the feel of a forged iron – the Limit3D irons are the product of these innovative advancements and are an industry first in performance and manufacturing.

The fully 3D printed 316L stainless steel body features an internal lattice structure that allows 33 per cent of the overall club head weight to be repositioned without sacrificing strength.

The unique design of the Limit3D allows for up to 100g of tungsten to be placed in the heel and toe areas of the club head, creating a low centre of gravity (CG) and an exceptionally high moment of inertia (MOI) relative to the shape and size of the club.

The result is a compact blade shape with a low CG location, high forgiveness, and distance comparable to that of a player’s distance or game improvement model like Cobra’s King TEC or TEC-X irons.

After becoming the first golf company to introduce a 3D printed steel putter in 2020 (using HP Metal Jet PBF 3D printing) and then following it up with a full line of 3D printed multi-material putters in 2021, engineers at Cobra set out to be the first to apply the new technology to iron design.

Cobra’s engineers say that nTop’s design software coupled with the use of additive manufacturing is the speed at which they were able to create and test prototypes. nTop’s software capabilities allowed the team to automate the design exploration process and make iterations two times faster to speed up the development process significantly.

The faster process also allowed Cobra’s R&D team to test a variety of lattice designs to optimise internal mass distribution and acoustics, resulting in a final product that exceeded expectations in looks, performance, and soft feel to appeal to the most discerning players.

Mike Yagley, VP innovation & AI at Cobra Golf, said: “nTop’s computational design tools integrated with 3D printing allowed us to create an incredible new design that looks and feels like a forged blade but performs like a larger, game-improvement iron. No one has done this before, and we’re excited to introduce these unique irons to the world.”

“Our new Limited-Edition 3D Printed irons represent Cobra’s dedication to pushing performance and technology to the limits,” added Cobra Golf VP product architecture Jose Miraflor.

“These incredible new irons are the most significant technological advancement to happen to the category in the past 20 years and offer a look into the future of golf club design and performance.”

There are only 500 sets available worldwide 3D printed irons (350 in US and Canada), starting on 7 June these ultra-premium limited-edition clubs will be available for custom order only in the US and Canada.

Retail price will be $3,000 for 4-PW set configurations in RH only with a wide selection of aftermarket steel and graphite shafts, and grips.