AMUG 2021 went ahead, despite the impact of travel restrictions and social distancing measures. Our correspondent SJ found much to enjoy (and learn) at the event held in Florida, USA last month

I look around, slightly confused. Then I look back at the panel host. She smiles warmly, or at least I think she does. It’s hard to tell, because of her face mask. I ask again, “So… I can literally just go and sit with whichever subject matter expert I want to, and start asking them questions?” She nods.

As I squeeze myself into an ongoing conversation, a woman is explaining the current situation regarding FDA [Federal Drug Administration] rules and getting approvals for metal implants. “And that,” she concludes, “is why Class II medical devices are so complicated.”

I wait for a moment, then raise my hand. She assures me that’s not necessary. This is an open space, she says, gesturing for me to continue. Blushing, I clear my throat, adjust my mask and ask my question: “Are the qualification pathways for metal AM parts similar for medical and aerospace. Which one do you feel is more stringent – if you don’t mind sharing that information?”

She doesn’t mind at all. It’s an excellent question, she says. She’s glad I asked.

And so my visit to the 2021 AMUG Conference continued, with me wandering from room to room, conversing with high-profile LinkedIn celebrities and the most knowledgeable members of the industry. I asked all of my wildest questions and I got frank, honest answers in return. Questions that I didn’t feel were significant enough to ask over email were suddenly hot topics in dinner conversations: What machine are you using? How’s the service with that? Do you have one of the larger printers? How does your factory floor handle the footprint? How many lasers does that one have?

For me, this was an amazing opportunity to shoot questions in rapid fire at influential members of the AM community. But I found that I personally was only asked one question, over and over again: “So, SJ, what do you think of AMUG?”

AMUG 2021 – A different vibe

Back in 2018, AMUG played host to 1,705 attendees. In 2019, there were 2,064 attendees. With the cancellation of the 2020 event, due to Covid, I had anticipated a large surge of people at AMUG 2021, all eager to get back to in-person events. At the time of writing, the official numbers aren’t available, but from my queries, it seems that some 1,100 people descended on Orlando for the conference. That’s about half the usual attendance.

Of course, travel restrictions kept most people from the UK and Europe from journeying across the pond. The same applied to US attendees residing in states hit harder by the virus and imposing more stringent rules around inter-state travel. Most notable was the absence of many additive companies based on the US West Coast.

With many new rocket companies signalling their moves towards AM, that was a disappointment. Also not in attendance were the big vendors and their absence was profoundly felt. No Stratasys, no DesktopMetal, no EOS, Carbon, GE or HP.

Some might argue that it was foolish to attend a conference while the virus (and its variants) are still ravaging the globe. Most attendees I spoke to personally said they hadn’t travelled until they’d at least had their first vaccine dose. That was slightly reassuring, but I still kept a vigilant watch over every crowd for anyone showing symptoms of sniffling, sneezing, coughing, fever or chills. I’m sure plenty of others were doing the same.

AMUG 2021 – Hot topics

Given the reduced size of this year’s expo floor at AMUG, it was a little hard to gauge which industry trends are really grabbing the most attention, but here’s my personal take on the themes that really stood out for me.

Hybrid manufacturing: The combination of additive and subtractive manufacturing within the same machine is a hot topic right now. Sure, the machines may be costly and the technology comes with a steep learning curve. But hybrid manufacturing can drastically reduce lead times for printing and machining of a specific part. There’s a side bonus, too: reduced shop-floor footprint. This technology is currently geared for prototyping, repair and lowvolume production.

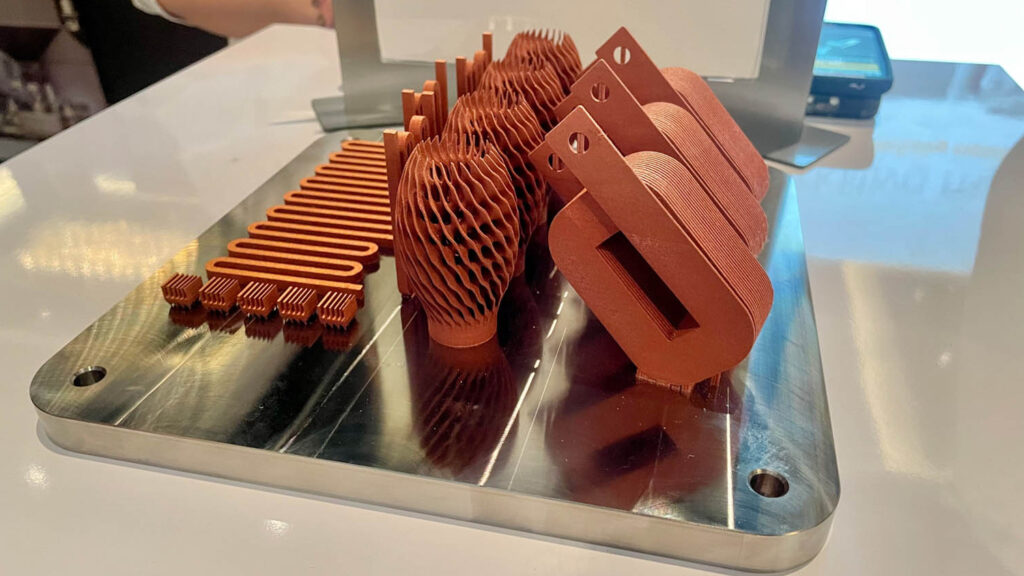

New materials: The expo floor at AMUG saw the appearance of new powder suppliers and a showcase of exotic materials. Most notable was the focus around bringing refractory metals into the wider AM world. Tantalum was a big point of focus; with its ability to perform at both subzero and high temperatures and its resistance to oxidation, it’s an excellent candidate for future space applications. Plus, its wear-resistance properties and biocompatibility are garnering interest from the medical market, too.

Binder jetting: Binder jetting may have been around for two decades or more, but it’s currently enjoying a moment in the limelight as a more cost-effective alternative for DMLS [direct metal laser sintering] for metal AM parts. This prompts me to wonder if its recent widespread adoption is driven by software, specifically simulation software, which allows users to accurately predict binder jet shrinkage before printing.

Qualification/regulation: At this year’s AMUG, ASTM International debuted its new certificate course in quality assurance for additive manufacturing. Topics covered include linking quality to certification and qualification systems; effectively demonstrating personal skill levels; and tips on lean manufacturing methods, tracking performance, deviations and in-process monitoring. I was pleased to see the wide breadth of topics in addition to the basics.

A learning experience

On the whole, if I had a criticism to make about AMUG 2021, it would be this: while I was excited for all the learning opportunities on offer, I was disappointed by the lack of ‘how to’ content around design for additive.

For example, there were several panels on how to choose an AM part for your business, but not many panellists discussed their design process or the lessons learnt from it.

That said, I was exposed to a much broader scope of the industry than I would usually experience. I learnt about new materials. I heard about innovations in other sectors like automotive and motorsports. I saw machines I’d never even heard of and met vendors I’ve never seen pop up on my LinkedIn feed.

Someone had to go first. For this (hopefully) post-pandemic year, I think the folks at AMUG were the best people to do it. AMUG provided an atmosphere that was as safe and welcoming as possible, one that encouraged attendees to get the most from the networking activities provided. I can now look forward to attending other conferences this year with greater confidence, but AMUG has set the bar high – or should that be the build volume?

Either way, I hope other event organisers are watching and can carry some of the lessons learned into their own events aimed at our community. These include RAPID (which is scheduled for September 2021) and Formnext (November 2021).