Fortify has added to its 3D printing product line-up with the new Flux 3D model leveraging its 3-axis magnetic field technology for aligning fibres and particles in resins.

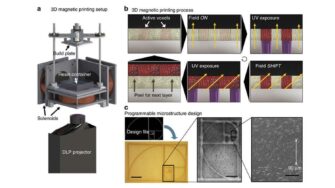

All Fortify 3D printers employ the company’s patented processing technology, CKM (Continuous Kinetic Mixing), allowing for the printing of heavily filled photopolymers while maintaining homogeneity, yet its other proprietary technology, Fluxprint magnetic alignment, is now available in two configurations.

The Flux Core is now the name for the baseline 3D printer, which includes CKM and is ideal for processing viscous particle filled resins where magnetic alignment is not required.

The Flux One, launched last year, now adds Z-axis magnetic field alignment to the baseline model, while the new Flux 3D leverages full 3-axis magnetic field technology to align fibre in any axis throughout parts as they are printed.

“The novel technologies built into the Flux One printer can be leveraged for a variety of use cases,” said Fortify CEO Josh Martin.

“While there is room for growth in the tools and fixtures market, an area that Fortify is currently providing value in with our reinforced materials, there is an order of magnitude greater market potential for end use part applications.

“By providing versions of our Flux printers tailored for specific use cases, we are giving users the power to go after these markets.”

In addition to the hardware solutions, Fortify has announced the availability of Flux Developer, its software platform for its full family of 3D printers.

Fortify says that Flux Developer gives users the ability to push the limits of material properties by opening access to all processing parameters. With this expanded processing window, users can control variables such as exposure time and intensity, material flow, resin temperature and viscosity, and even the build plate mechanics, as they develop and onboard new materials.

“With growing excitement around our capability to process filled photopolymers, we are seeing demand from customers who want to explore materials beyond our current offerings,” said Ben Arnold, VP business development at Fortify.

The company also stated that funds from the company’s recent equity funding round will be used to scale up manufacturing at Fortify.