Nano Dimension has acquired Additive Flow and its multi-material AM optimisation software capabilities, led by its consultancy work and its FormFlow product.

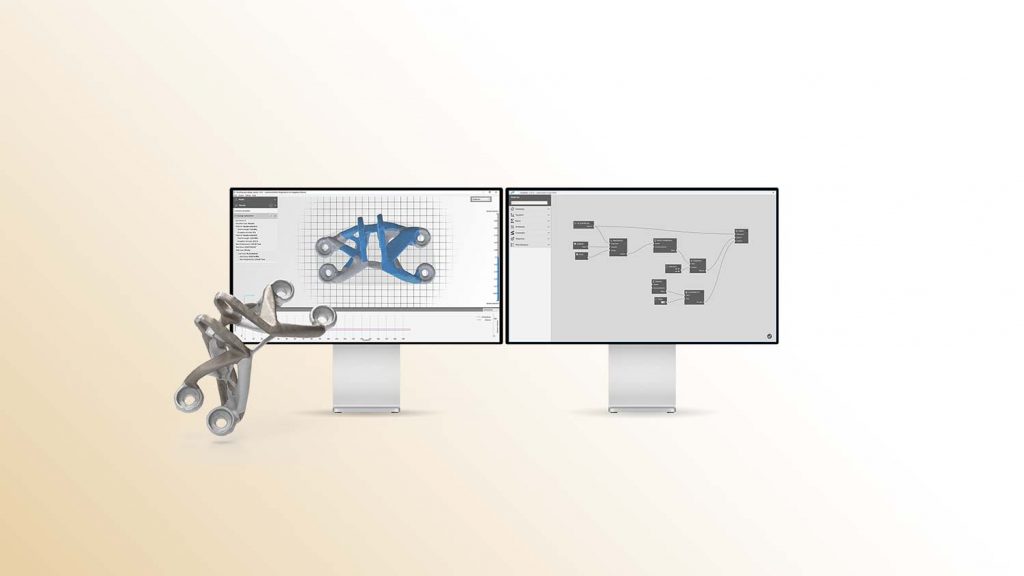

FormFlow is a software for the simultaneous optimisation of the entire AM workflow, while the company has worked with the likes of Saint-Gobain, Royal Haskoning, Tata Steel and Zeiss to maximise their AM value.

Their product addresses design, production, and quality decisions, while optimizing for cost, weight, manufacturing productivity, and manufacturing yield – all simultaneously.

This acquisition signals a successful milestone in Nano Dimension’s product development roadmap, which to date has been very focussed on additively manufactured electronics (AME), with it stating that ‘Computer-aided engineering and design components are a core part of the company’s design-through-manufacturing product strategy’.

Additive Flow CEO and CTO Alexander Pluke, commented: “The Additive Flow team is thrilled to join Nano Dimension. Our solution was born out of real engineering challenges we faced to harness the capability of advanced manufacturing. Our platform is built from the ground up to handle all the complex data and decisions of digital engineering, so teams can focus on their key goals.

“We are fortunate to have found a great partner in Nano Dimension where our innovation can be leveraged to its maximum potential. We look forward to building on our impressive track record and continuing to develop Additive Flow’s software and enhance Nano Dimension’s leading AM and AME product offerings.”

Nano Dimension says that Additive Flow’s AI- and GPU-accelerated software will enhance its customers to replicate, design, and augment AME electronic components’ prototypical layouts, in a rapid and cost-effective manner. Additive Flow’s core technology will be integrated into Nano Dimension’s proprietary design package suite, Flight.

Nano Dimension Senior CTO Nick Geddes, added: “We have been looking at the software market for simulation and optimisation offerings for some time. There are many strong solutions in the market that do certain elements of those complicated tasks, but it is Additive Flow’s product that stood out in terms of the functionality we needed for a holistic solution, especially in the context of our requirements across AME and multi-dimensional polymer, metal and ceramic AM.

“The acquisition will add considerable firepower to the ability of our customers to leverage our leading digital manufacturing solutions.”