3D Systems has launched new Figure 4 3D Printing materials – including new elastomer and jewellery resins – as well as a new quick casting material for its SLA 3D Printers.

Rubber-65A BLK is a new ‘production grade’ mid-tear strength elastomer with high elongation at break for flexibility, strength and durability, as well as being engineered for long-term environmental stability.

These properties should enable production of end-use elastomeric parts with a high degree of accuracy and the Figure 4’s party-trick of minimal scarring from supports.

Figure 4 Rubber-65A BLK is also biocompatible capable (per ISO 10993-5 and ISO 10993-10) so it can be used to produce grips and handles as well as padding for splints and braces.

3D Systems began 2020 with the launch of Figure 4 Jewelry [sic] – a specially designed and optimised solution for the burgeoning 3D printed jewellery market.

The solution launched with the jewellery casting workflow using Figure 4 JCAST-GRN 10 material which is now joined by the Figure 4 Jewel Master GRY resin.

Designed to be used as a versatile master pattern material for high volume jewellery silicone moulds and for prototype/fit models.

The material boasts high heat deflection temperature, ensuring compatibility with a range of silicones for creating master patterns.

Figure 4 Jewel Master GRY is well suited for users needing to produce high definition master patterns for making silicone or RTV moulds – especially for high volume, mass production of designs.

3D Systems also states that the material is also suited for functional prototyping – snap-fit and stone-in-place testing – while biocompatibility standard ISO 10933-5 for cytotoxicity, makes it safe for try-ons and fittings.

Figure 4 Jewel Master GRY and Rubber-65A BLK are planned for general availability in late June 2020.

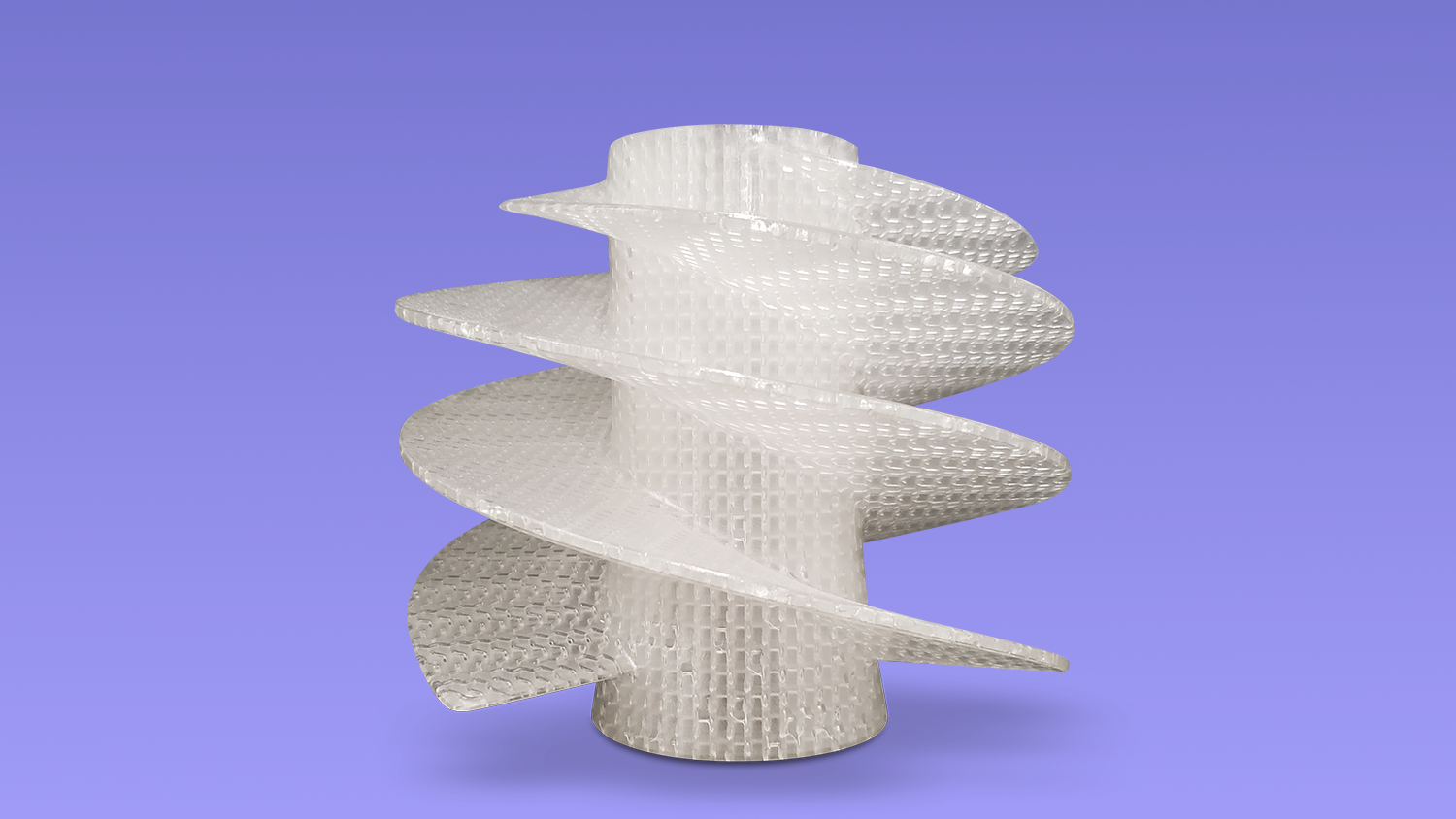

3D Systems have also launched a new casting material and two new post-processing materials to enhance its QuickCast platform.

Accura Fidelity is billed as an ultra-low viscosity, antimony-free stereolithography (SLA) resin with clean burnout that is designed to create patterns for a variety of castable metals, including titanium and aluminium alloys.

Accura Fidelity should enables rapid creation of medium to large, lightweight, and easy-to-handle casting patterns, which can lead to increased casting yields.

“Our team has continued developing new materials across our plastics portfolio to address a broader set of production applications and providing data sheets with key test results and performance specs to make it easy for our customers to make the optimal material choice for their needs,” said Menno Ellis, SVP and GM plastics at 3D Systems.

“Our material scientists and technical experts have leveraged decades of experience to engineer these high performing materials to deliver accurate, economical, and repeatable results to enable our customers to maintain competitive advantage.”