Designing and manufacturing sustainable products is no longer an altruistic activity aimed at saving the planet. Although it’s commendable that businesses incorporate sustainable measures into their operations, sustainability has become a significant factor affecting the bottom line for companies.

This shift is driven by increasing consumer demand, stringent regulations, and corporate goals to reduce their carbon footprint. As a result, companies are now compelled to devise new strategies for creating more sustainable products and manufacturing methods.

But the truth is that designing and manufacturing sustainably has traditionally been challenging. The industry is constantly juggling time and cost constraints, and lifecycle analysis often comes at the very end of product development.

The good news? A sustainable-first approach is becoming much easier. Here are five ways to get started and begin making a positive impact on the planet and your bottom line right away.

1. Design sustainably from the very start with new digital tools

According to McKinsey & Company, up to four-fifths of a product’s lifetime emissions are determined by decisions made during the design stage. Placing a focus on sustainable choices and outcomes at the beginning of the product development process is imperative. Advancements with design and make software now help make those decisions easier and earlier.

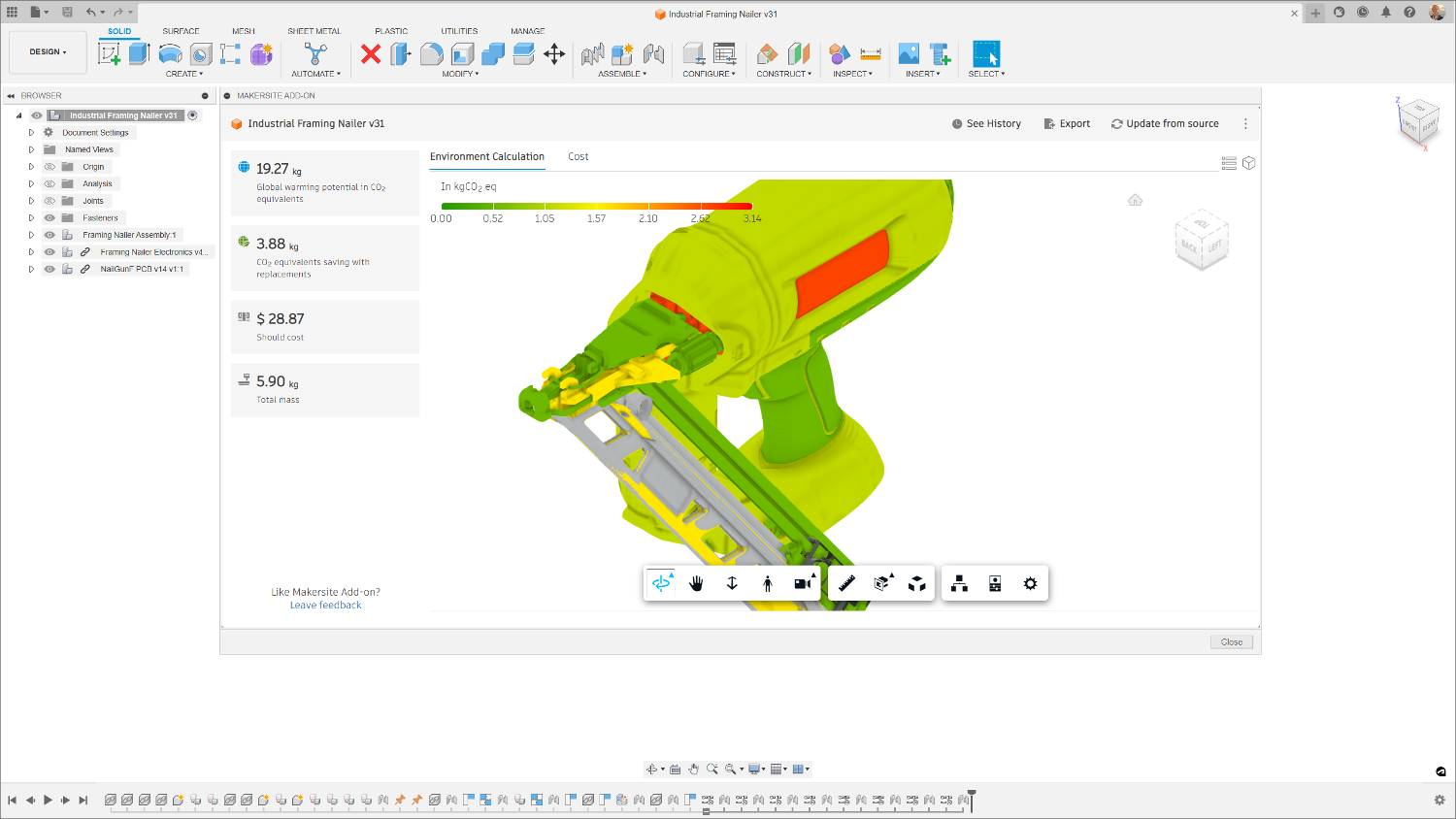

With the Makersite Add-on for Autodesk Fusion, you can instantly receive and analyze carbon and materials cost assessments directly in the model—all without compromising profitability. Immediate recommendations for sustainable alternatives and lower-carbon materials are also available. It all works by converting a CAD model into a Bill of Materials (BOM) and requesting Makersite to calculate climate change impacts as well as cost estimates of the BOM.

The new Manufacturing Sustainability Insights Add-on for Fusion takes this one step further with analysis of embodied carbon. Embodied carbon is a measurement of the greenhouse gases emitted to the atmosphere. With the MSI Add-on, you can gauge emissions associated with the extraction and processing of a material, transportation of a raw material to the manufacturing location, and the impact of manufacturing processes.

Now it’s possible to choose better materials and manufacturing methods with all the data right at your fingertips. And this integration doesn’t just offer a pathway to greener products—it’s a straightforward method to reduce carbon emissions, enhance sustainability, and streamline reporting.

2. Save materials with AI and generative design

Artificial intelligence (AI) has taken the world by storm over the past couple of years. The design and manufacturing industry is already seeing new advancements for sustainability with the use of AI, from automating repetitive processes to analyzing shop floor operations and more. One of the biggest opportunities is lightweighting products and saving materials using generative design.

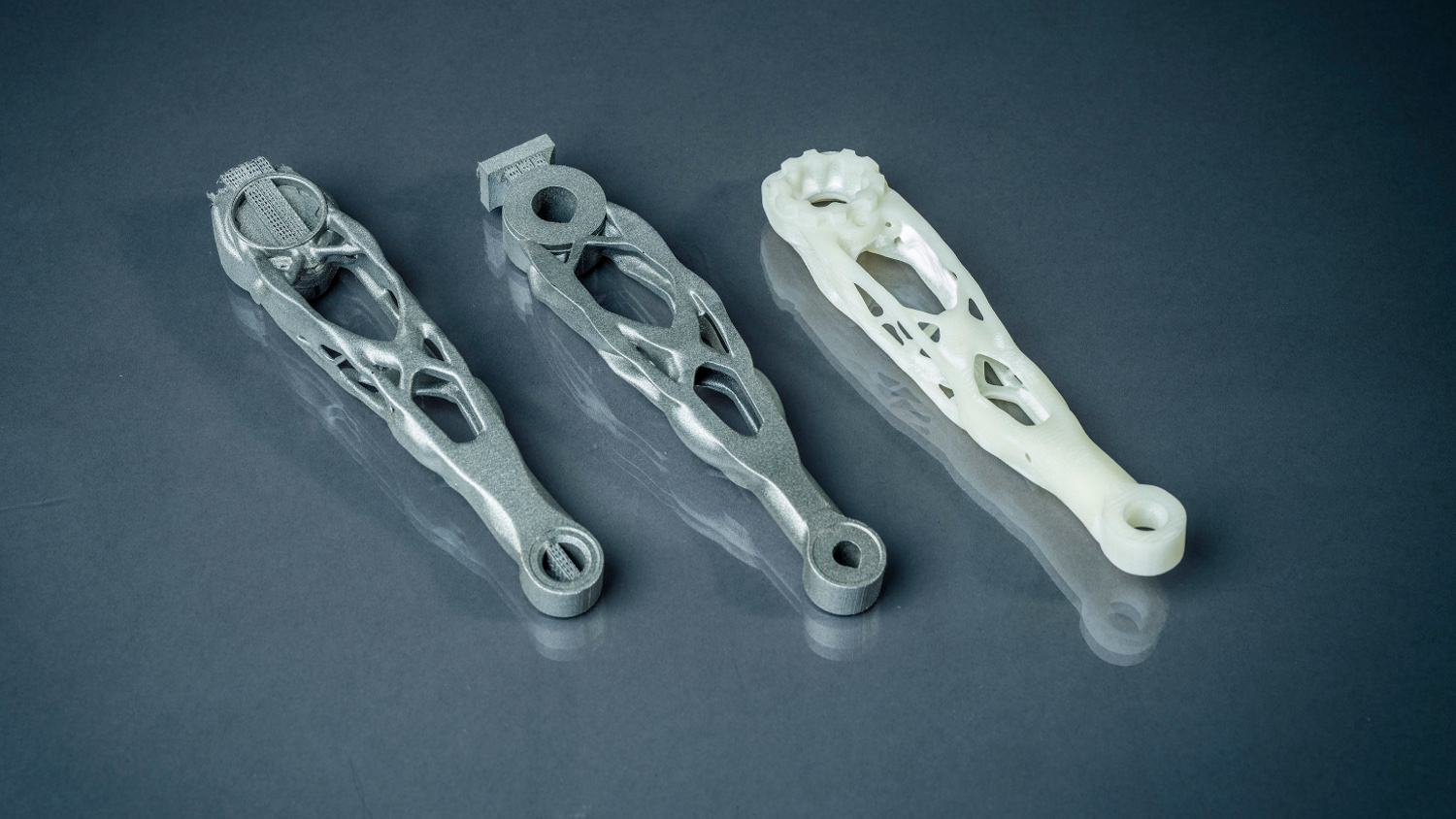

Generative design is a tool that leverages AI to automatically create hundreds of design options based on desired parameters for weight, strength, material, and performance enhancements. Teams can then choose a design to move forward with and optimize it as needed to achieve specific goals.

Generative design in Fusion reduces the weight of products by identifying the minimum amount of material needed to meet performance requirements. It can also help identify the optimal combination of materials and thicknesses for further savings.

3. 3D print prototypes and final parts and products

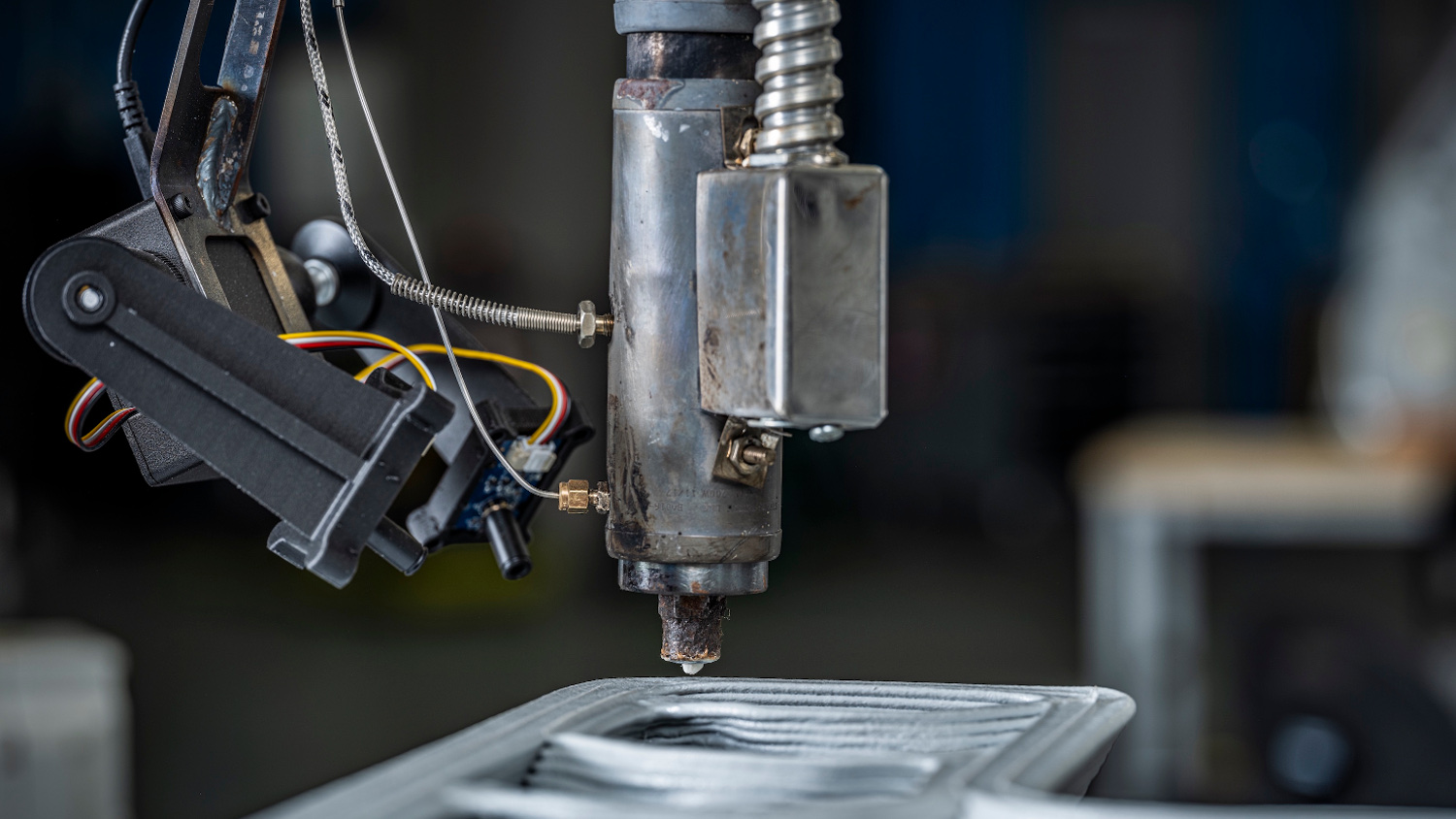

Additive manufacturing has provided new opportunities to design and manufacture parts and products much more sustainably. According to a recent Environmental Science & Technology paper, “additive manufacturing has been used to reduce material use in final parts by 35–80%, and recent publications have predicted that additive manufacturing will enable the fabrication of customized products locally and on-demand, reducing shipping and material waste.”

By using 3D printing as an alternative to subtractive manufacturing, material waste and energy consumption are significantly lessened. Alternative materials for additive manufacturing continue to grow with recycled plastics and biodegradable options now available.

With Fusion, you can quickly create and 3D print prototypes to validate and produce final parts that are lighter and stronger. Thermal simulation tools in the Fusion Manufacturing Extension validate the 3D printing process, avoiding print failures.

4.Take advantage of nesting

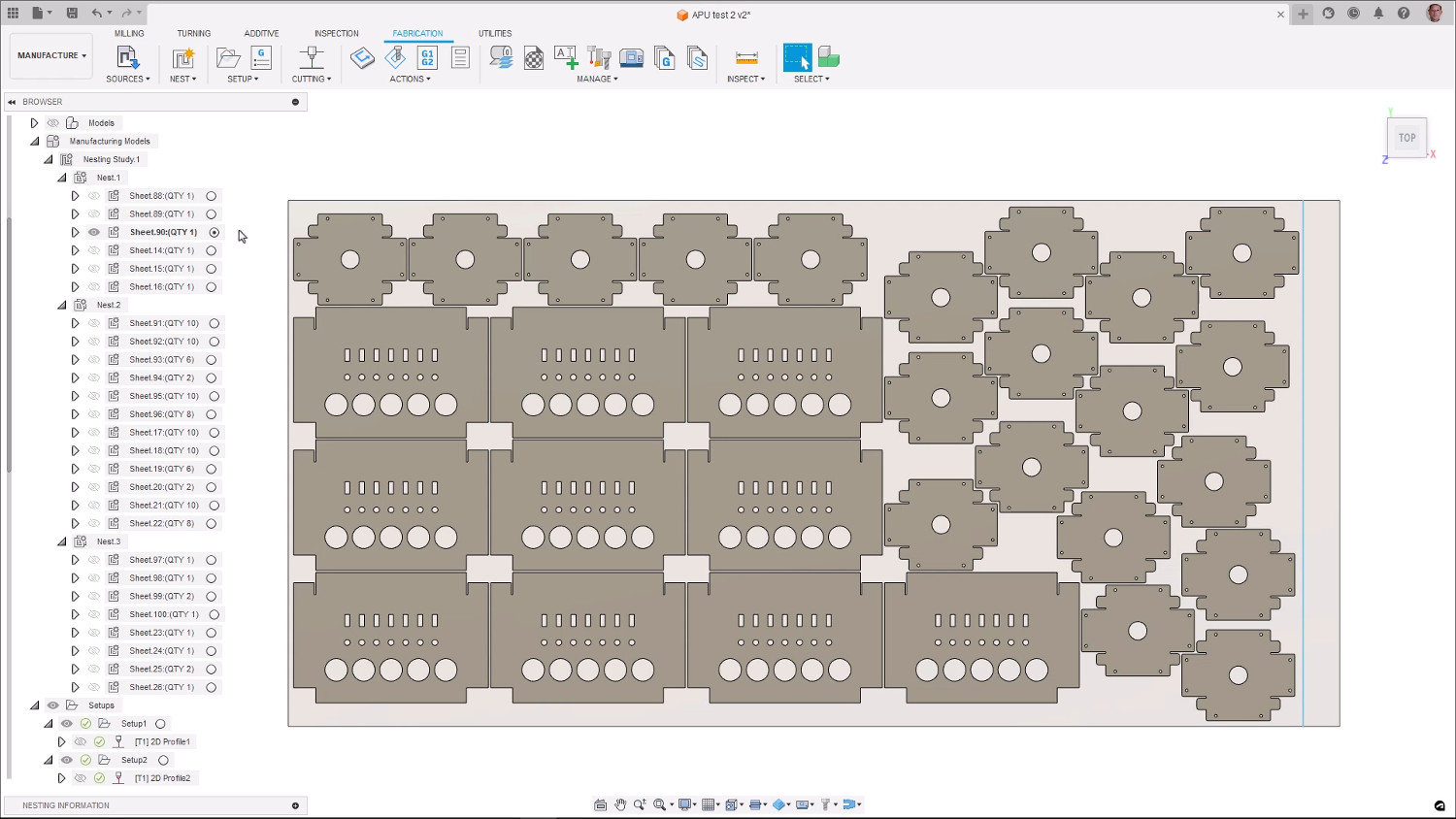

Even with all the best efforts for precision, machining still creates waste with a block of material. When using subtractive manufacturing, nesting is an ideal process for a more sustainable approach.

Nesting optimizes the layout of multiple parts and shapes to reduce raw material waste and improve efficiency. By analyzing shapes, quantities, and sheet sizes, the Autodesk Fusion Manufacturing Extension delivers a new level of automation and immediately generates a nesting layout of parts for optimal material use by analyzing shapes, quantities, and sheet sizes. It’s a win-win-win for manufacturers as it saves production time, cuts costs, and makes the processes more sustainable.

5. Create sustainable practices on the factory floor

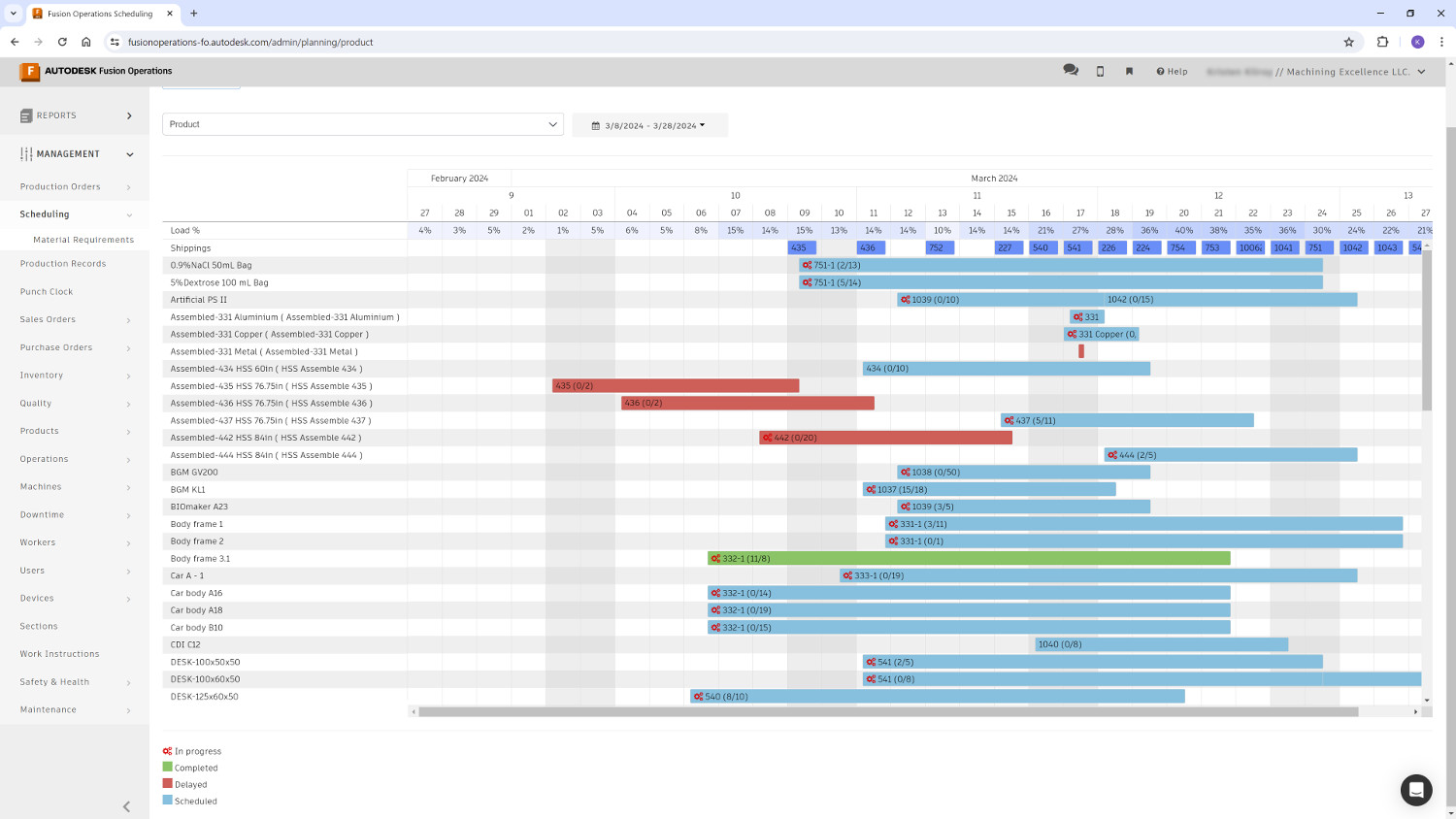

Improving the efficiency of manufacturing operations can significantly reduce a manufacturing company’s carbon footprint. This is especially evident when taking a digital approach on the factory floor with tools like Autodesk Fusion Operations.

Removing paper-based processes is a first step that not only reduces waste, but also delivers transparency and accuracy for production. Access to real-time data improves the production process, resource allocation, and inventory management. Tracking preventative and maintenance operations ensure machines are running at peak efficiency, reducing energy usage. All these combined make a positive impact and create new opportunities for more sustainable manufacturing outcomes.

Getting started

Starting with small, simple steps toward sustainable approaches and processes leads to big changes in the long run. Whether it’s adopting new tools for sustainable-first choices early in the design phase, embracing additive manufacturing, adopting more efficient subtractive manufacturing techniques, or leveraging generative design for lightweighting, companies can begin reaching a new level of sustainability for both business goals and the planet.

Try Autodesk Fusion for free today