MSC Nastran v2018.2 for powertrain simulations now allows engineers to cover a wider range of design possibilities and examine the NVH characteristics of transmissions, car engines, and powertrain systems through a direct integration with AVL Excite.

As the world’s widely used MBD software for simulation of rigid and flexible powertrains, AVL Excite can now be used with MSC Nastran to increase the accuracy of Multi Body simulations by providing a better representation of the flexible components.

Similarly, FEA engineers can benefit from this integration to examine each component with realistic boundary conditions and dynamic loads. Direct export of AVL Excite input (.EXB) files from MSC Nastran makes data transfer much easier and faster, eliminating the need for creating and translating large intermediate files.

A streamlined workflow allows engineers to obtain a full characteriaation of structural response by leveraging the nonlinear solution of MSC Nastran (SOL 400) to include contact nonlinearities as well as preloaded conditions in their powertrain simulations.

Additionally, MSC Nastran can read back output results from AVL Excite for further dynamic and acoustic analysis of sound radiations generated from internal combustion engines and other components.

This should also prove beneficial for vehicle durability simulations, taking advantage of the embedded fatigue capabilities of MSC Nastran to obtain fatigue life and damage responses of components.

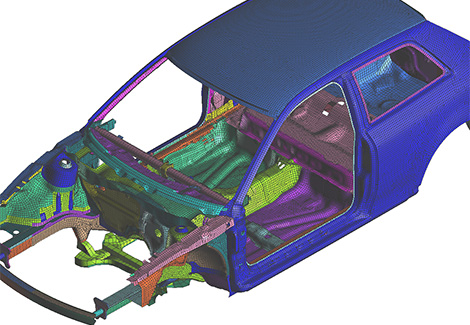

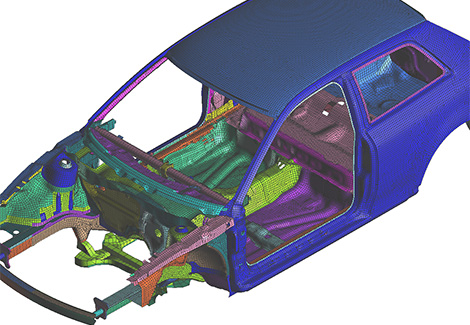

From a modeling perspective, MSC Nastran is able to perform a model check to review the initial contacting conditions of thousands of car parts before running the analysis, especially useful for contact models that involve curved geometry surfaces or unintentional gaps and overlaps.

These initial geometry adjustments are usually performed internally and cannot be seen in the input files. MSC Nastran 2018.2 provides contact verification methods that allow users to examine and review initial geometry adjustments and make changes if necessary.

The new contact checks provide important information about the contact bodies, their initial status, and geometry conditions in various output files.