Education excels when students go beyond learning and acquire expertise that prospective employers can’t resist. The University of Sunderland has invested in a ZScanner to help improve the career prospects of its students

University students use 3D laser scanning for SU Racing Formula Student

The goal of providing marketable skills to its students is what drove the University of Sunderland to bring high-resolution 3D laser scanning to its Digital Factory.

The Digital Factory is a training and technology transfer project focused around digital engineering technologies. The project is delivered by Institute for Automotive and Manufacturing Advanced Practice (AMAP), a department of the Faculty of Applied Sciences at the University.

A Z Corp Spectrum Z510 is used to produce models for casting heritage parts

The Digital Factory Project’s students and professional consultants provide technical training and support to North East UK businesses in computer-aided design, engineering and rapid prototyping. For example, the Digital Factory team recently helped 3M UK PLC improve manufacturing accuracy and reduce costly waste at its plant in Aycliffe.

“We had a long list of demanding requirements for our 3D laser scanning technology, and the ZScanner 700 was the only one that met them all,” says Sajid Abdullah, lead consultant with the Digital Factory. “It was the perfect tool for the 3M project.”

Choosing their solution

The University of Sunderland evaluated scanners from NextEngine, Metris and Roland. “As the only self-positioning scanner, the ZScanner is easiest to use by a long shot,” says Abdullah. “The self-positioning laser is great. It requires no turntables or tripod-like fixtures like the others do. You just hold the scanner in your hand, swipe it across the surface of the object, and let the lasers lock on.

“The ZScanner’s unique portability means we can tote the scanner to our industry partners instead of asking them to come to us,” he adds. “It also means we can share the scanner easily among the university’s engineering department, the Digital Factory and the nearby Nissan plant, where we do a lot of consulting.

“Being handheld, the ZScanner can easily digitise both large objects and areas that are hard to reach, like automotive interiors,” continues Abdullah. “One more thing: the ZScanner 700 was the only one with its own reverse-engineering software to capture and repair point cloud data. Others required a separate purchase of CAD software to clean, repair and produce CAD models.”

Preserving the artefacts

Several months after the 3M project, the Digital Factory team used these capabilities to tackle an entirely different manufacturing problem – replacing 19th century artefacts at County Durham’s Beamish Museum, which tells the story of the North East during the 1800s and early 1900s.

Three exhibits were missing critical damaged parts. An 1877 Lewin Locomotive had a broken steam injector, a tram had a broken handrail, and a cart had a broken wheel. The Digital Factory team visited the museum, scanned the damaged parts, and restored the resulting data to the original using 3D CAD software, giving the museum detailed designs with which to create new parts.

In the case of the steam injector, the Digital Factory team went a step further and used its 3D printer, a Z Corp Spectrum Z510, to produce a physical model – accurate down to the threads – which were in the casting pattern for a brass part.

Bosting auto performance

University students also use 3D laser scanning on their own projects, including SU Racing Formula Student. Formula Student is a program challenging European university students to design, build, develop, market and compete as a team with a small single-seater racing car.

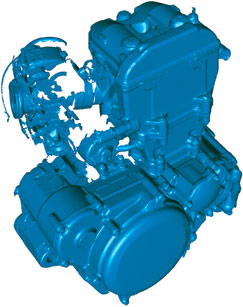

University of Sunderland race teams have begun scanning their engines to provide 3D CAD data to ensure proper fit in the vehicle chassis. They’re also scanning hand-shaped Styrofoam prototypes and making auto body parts directly from the CAD data, reducing design time while using the Z510 to create prototypes for suspension systems and other parts to share with suppliers.

“3D scanning, and printing as well, have delivered great benefits to our students and business partners alike,” says Abdullah. “A lot of companies haven’t been exposed to the multifaceted role of laser scanning in the manufacturing arena. Our students, however, are becoming experts and are going into business situations with valuable knowledge to impart. They hit the ground running, and their employers immediately benefit. It’s the beginning of a long relationship.”

zcorp.com / sunderland.ac.uk/amap

The University of Sunderland has invested in a ZScanner to help improve the career prospects of its students

No