Boom Supersonic, the company building history’s fastest supersonic passenger airliner featured in our hallowed pages back in 2017, has partnered with Velo3D for the metals additive manufacturing needed for its XB-1 demonstrator aircraft.

The first independently-developed supersonic jet that will prove the key technologies in-flight for safe, efficient travel at Mach 2.2 (1,687mph), the XB-1 combines over 3,700 parts and some of the most advanced technologies including advanced carbon fibre composites, a refined delta wing planform, and an efficient variable-geometry propulsion system.

Boom and Velo3D have already conducted validation trials, which performed ‘accurately and to desired results’, and now Velo3D is developing two titanium flight hardware parts for XB-1 to be installed on the prototype aircraft in early 2020.

These ‘Intelligent Fusion’ 3D-printed parts are installed as part of the ECS system and ensure the aircraft can achieve safe flight at all conditions.

“Boom is reimagining the entire commercial aircraft experience, from the design, build, and materials used,” said Velo3D CEO Benny Buller, before revealing that another major Aerospace OEM will have as many as five of Velo3D’s Sapphire 3D printers before the end of the year.

“Our technology is designed to help innovators like Boom rethink what’s possible, empower advanced designs with little or no post-processing, and enable an entirely new approach to production.”

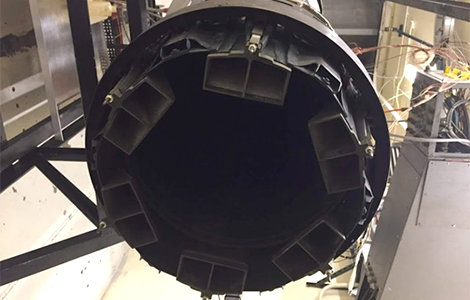

Engine ‘mice’ 3D printed on the Velo3D Sapphire system, as installed in the afterburner section of the XB-1 engine

Previously, Velo3D had completed a project with Boom to print some components for the engine (along with two other 3D printing companies) that will be powering the XB-1.

The 3D printed engine ‘mice’ from Velo3D were installed in the exhaust of one of Boom’s GE J85-15 engines that are being tested at the United States Air Force Academy in Colorado Springs.

As described by Ryan Bocook, a manufacturing engineer at Boom: “The mice allow for high engine operating line testing, ensuring we can achieve safe flight at all conditions.”

The printed parts facilitate this testing by reducing nozzle area to help simulate engine stall condition while the engine is running from part power to mil power. This testing also includes flow distortion simulation at the inlet (caused by Boom’s inlet design and validated by CFD analysis and wind tunnel models/tests).

Engine ‘mice’ produced using Velo3D’s technology

This work also helps validate one of Velo’s value propositions, which is focused on variability reduction and quality assurance through process metrology and control.

Bocook has significant experience in this area, coming from GE’s Auburn, AL additive plant, where he worked as the quality manager.

“Certification and the required quality assurance are a considerable challenge with today’s metal AM systems,” Bocook said. “Velo3D’s Intelligent Fusion technology should be a significant step forward in terms of process control and metrology.”