Swindon Powertrain is taking a half-century of know-how in performance engine development and design and channelling it into a bold mission to conquer the electrification market, as Al Dean reports

The electric vehicle (EV) market is hotting up. From big-name OEMs and small start-ups with huge ambitions, to enthusiasts looking to breathe new life and power into classic motors, it seems everyone’s on the hunt for new approaches that sidestep the internal combustion engine (ICE) and the emissions that come with it.

Take, for example, Swindon Powertrain. Established a half-century ago, it’s hoping to take a wealth of knowledge of the ICE environment and use it to build a reputation for itself in automotive electrification products.

That’s a bold step for a company with such a formidable track record of work on more traditional engines, including rebuilding and servicing Formula 1 engines such as the DFV from Cosworth.

Its services range from remaking single components right up to full rebuilds, and it also manufactures its own powertrain products, such as the engine that powered Ash Sutton to victory in the 2020 British Touring Car Championships.

The first step on the company’s journey into the brave new world of electrification was a conversation between its managing director and technical director about its future direction, says commercial director Gerry Hughes.

“As a company that has all of our rich knowledge and experience in internal combustion engines, we wanted to know how we apply that to the future,” he explains. “So it wasn’t a sudden switch that was thrown, but there has been a move towards ensuring we stay ahead of the curve and move into the area of electrification.”

Swindon Powertrain – First fruits

The first fruits of Swindon’s explorations marked a radical departure for the company.

Moving away from all things fourwheeled, the team instead turned its attention to the development of a hyper electric mountain bike, the EB-01. Packing an unbelievable 15kW of electric power into a hybrid aluminium/carbon frameset with regenerative braking, the company claims it’s the fastest, most powerful electric mountain bike available.

“The EB-01 was an exercise in looking at how we embrace electrification and investigating what we wanted to produce as a brand-awareness tool and a flagship product for a number of electrification products going forward,” Hughes explains.

The product continues to sell well, he says, and has been developed further since its launch, with new enhancements to both software and hardware – most notably the addition of high-density battery cells.

Alongside the EB-01, Swindon Powertrain has also developed its first electrical drive product, the HPD, or High Power Density unit. This is a compact, 80kW electric drive motor and gearbox, designed for quick and easy implementation.

In order to test this product during development and showcase its capabilities to would-be customers, the company decided to incorporate the HPD into the iconic Austin Mini.

Since then, it’s taken the idea one step further, creating a new commercial offering that provides an entirely new revenue stream. This is aimed at enthusiasts looking to convert their own Minis to electrification.

Swindon’s HPD E electric motors were designed from the ground up, from a clean sheet of paper. That enabled the team to scrutinise the physical elements of the motor, along with its power and size requirements, says Hughes, and then perform “all sorts of design and simulation of the electric machine, before it was even built and assembled.”

At the other end of the scale, the engineering and design teams can also perform simulations that compare the differences between an original ICE system and its electrified counterpart.

From there, they can determine what the shift from the former to the latter means in terms of acceleration, top-speed potential and other performance indicators, including driving range.

Swindon Powertrain – A new flagship product

The development of the E Classic began with an outsourced 3D scan of the Mini’s body shell. Capturing form in this way is no longer the ‘black art’ it once was, Hughes insists: “It’s now a fairly well-known process for us. The whole process of 3D scanning has improved: the scanning equipment, the post-processing and the preparation for moving data into CAD have become a lot less timeconsuming and a lot less costly.”

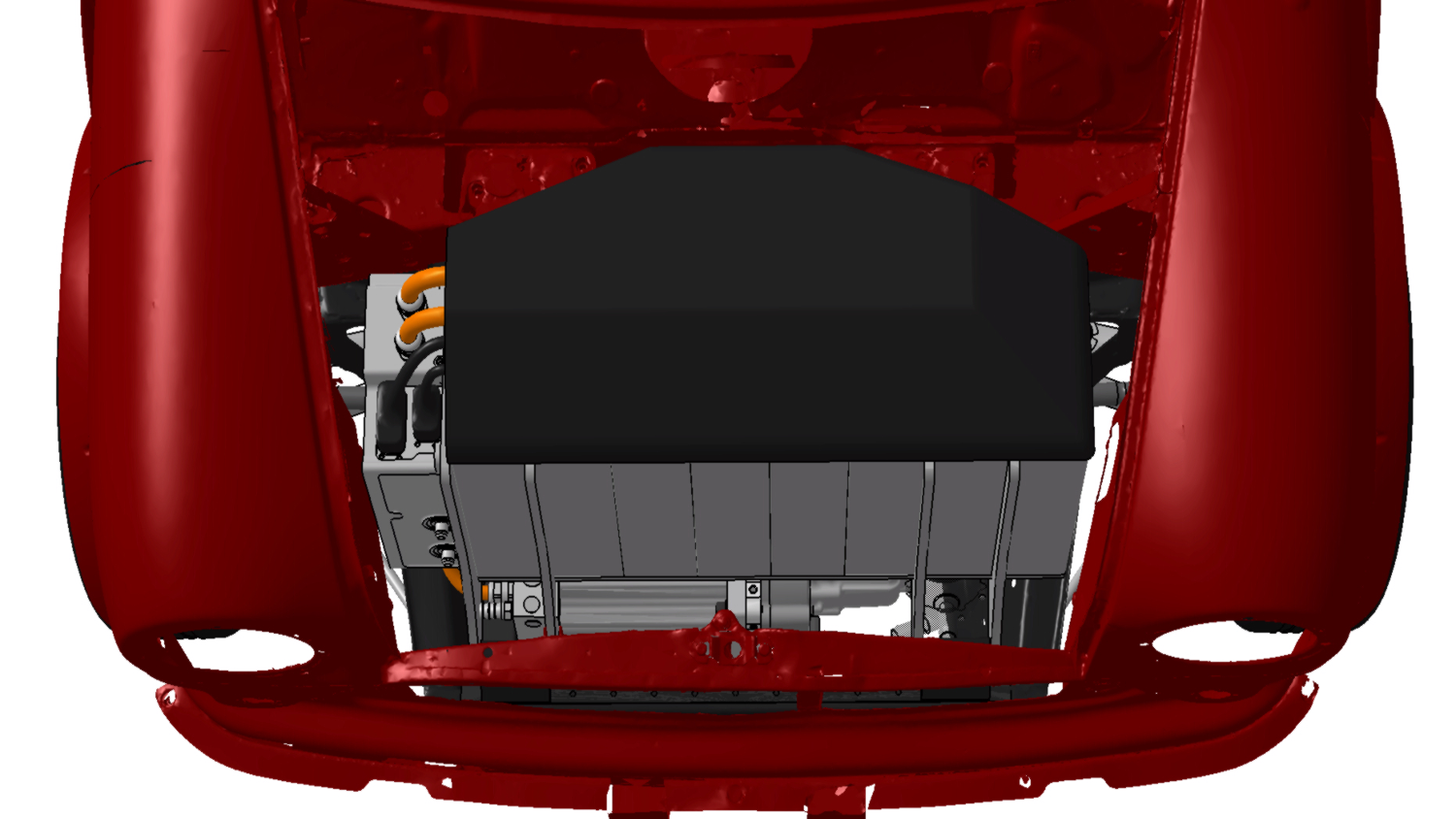

Once the donor body was scanned, it was brought into Catia V5. Then the team got to work with packaging not only the same electric motor and transmission, but also the battery pack.

The Mini project includes a modified body shell – a deviation from the approach used by other companies carrying out similar electrification work, which tends to focus more on maintaining a level of authenticity with a classic model, even sometimes ensuring that the conversion to electric is reversible, should the owner wish to take that step.

In Swindon’s case, however, the team wanted to make a statement. The Mini’s body shell was modified to include a 24kW/hour battery pack to help achieve their goals in terms of both driving range and performance. Hughes explains that, once the body-in-white was available in CAD, the process of designing components to fit within that space could really start to take place.

As he details, the team had a number of design specification points that it wanted to achieve. It needed something modular to build on, in terms of the power of the electric motor, and it wanted to give people a choice of drive ratios. The HPD was therefore designed to allow the fitting of different gear ratios, so the whole thing was conceived around modularity from the start.

The team also wanted to ensure versatility, so while the goal with this particular project was to fit the HPD unit into a Mini, it could just as easily find a home inside a vintage Escort, an off-highway vehicle, a competition vehicle, or a road vehicle. Simulation tools were employed to explore possible mounting points for the HPD, as the concept of versatility really was key.

“When you’re designing something that is going to be bought by a person in their garage, through to OEMs who might want to order them to slot into a sports car, van or other vehicle, it puts a little more emphasis on the design phase of the project,” Hughes explains.

“It also influences how you come up with a product that needs to be light, well packaged, well designed, but will also fit into a multitude of different vehicles. That’s quite special.”

That’s where Swindon Powertrain’s decades of experience in motorsport has stood it in good stead, using the latest materials, the latest techniques and the latest manufacturing procedures, he says.

“It might be a slow shift in how that energy is taken and converted into mechanical power, but our experience is used in the same way.”

The end result is the E Classic, an Austin Mini restored and retrofitted with an advanced electrification power train, boasting a brisk acceleration of 0-60mph in just 9.2 secs, 30-50mph in 4.3 secs and regenerative braking.

The car’s lower centre of gravity compared to the original (reduced by 44mm) delivers enhanced performance and handling. It has a range of 125 miles, and handily, removing the fossil-fuel tank has made the boot space larger, too.

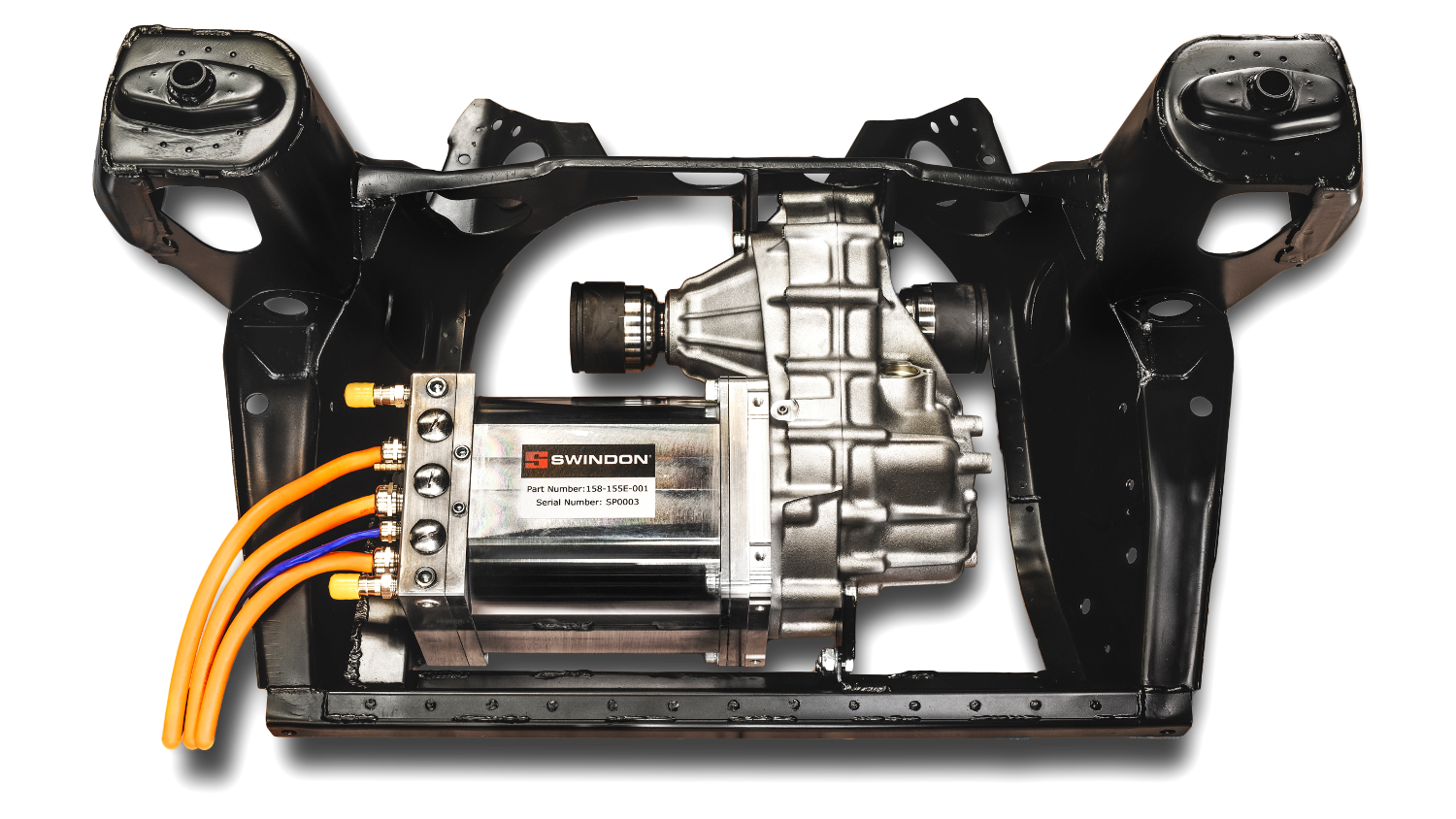

Alongside this flagship project, Swindon Powertrain has also just released details of its E Classic Kit. At the heart of the kit is Swindon’s 80kW HPD E Powertrain system, mounted to an original classic Mini front subframe.

This features brackets specifically designed for this installation, as well as purpose-designed inner CV joint housings, which allow the fitting of standard Mini driveshaft assemblies and comes complete with a standard differential.

There are also optional limited slip differentials, as well as other Swindon Powertrain EV components, such as 12 kWh battery pack, motor controller, onboard charger and DC-DC converter.

The road ahead

So what does the future hold for Swindon Powertrain, a company steeped in knowledge of and expertise in the performance ICE, but learning fast how to conquer the challenges presented by electrification?

The company will probably keep a foot in both the ICE and electric camps, Hughes says, but the balance of focus is likely to shift over time to the latter.

“I can’t see a point in the future where electrification is everything we do and we never touch an ICE project again, because there will always be opportunities for us to do one-off projects,” he says.

“We’ve got an engine downstairs at the moment which is being reworked and rebuilt, tested and sent off to the owner. It’s a very specialist engine and we’re one of the only groups that can remake components for that engine. It’s hugely expensive and [customers] come to us because they know we’ve got the knowledge and expertise.”

These types of vehicles, with these kinds of needs, will be around for a good while yet, he says, as will classic cars. “So I think there will always be a requirement for a specialist manufacturer, be it for camshafts or crankshafts, or for clean-sheet-of-paper, ground-up complete engines. But these will be more specialist applications going forward, rather than road-going vehicles.”

What he expects to see is a gradual transition to EVfocused projects. “At some point, we will look at the order books and we’ll be able to say that electrification has now overtaken what we’re doing as an ICE product manufacturer. It will be interesting to see how quickly that transition occurs,” he says.

“Electrification products are appearing on the market from the four corners of the globe. It would be really easy to flog the market with too many products, then lose focus. We are a small manufacturer of components, but ultimately, we want to ensure we can service the needs for the low-volume manufacturer and that’s where we’re ideally placed at the moment. That’s where our history has brought us to and where we feel comfortable.”

Some customers may simply want one component; others may require a complete offering. “It’s entertaining and it keeps us on our toes,” he says. “Some people are continuing to embrace electrification, and there are others that haven’t even made a start, and it’s interesting to have those initial conversations.”

Either way, he concludes, a revolution is certainly on its way – and Swindon Powertrain is here to help its customers navigate the road ahead, wherever it might lead.