Fingers activated by myoelectric sensors allow the wearer to complete tasks like tying shoelaces

The prosthetics industry is on the brink of change. From cumbersome, off-theshelf, ‘dumb’ limbs the technology exists today to create electronically controlled moving prostheses. But they often come with a hefty price tag, making them prohibitive to most.

However, Japanese start-up Exiii has produced a prosthetic prototype called Handiii with material costs of around £700.

The prosthetic not only combines a forearm and hand to replace the missing limb, but also gives the wearer the ability to move and control it using a myoelectric sensor.

The sensor is attached to the wearer, which senses minute muscle and nerve electrical activity (EMG). These signals are then sent to the electric motors and are used to control the movement of the hand to grip or pinch objects.

Taking control

DEVELOP3D was lucky enough to try out the Handiii at Dassualt Systèmes’ ‘Design in the Age of Experience’ event in Milan recently.

After a few minutes coaching by company founder, Genta Kondo, we managed to control the fingers of the hand to open and close a fist. With more practice, everyday tasks could be achieved such as grasping small objects, reading the newspaper, pulling up a zip or tying shoelaces.

Kondo’s idea for Handiii was formed in 2011, with design on the project beginning in 2013. Following its runner-up position in the 2013 Dyson Awards, Kondo and the rest of the team – Hiroshi Yamaura and Tetsuya Konishi – founded Exiii as a start-up business in late 2014.

A former Sony employee with expertise in robotics research, machine learning and artificial intelligence, Kondo’s aim was to create an everyday prosthesis with design and cost being key considerations.

As part of its development, and with support from the likes of the James Dyson Foundation and Google’s charitable division, a version of its design has been made open source, with STL files for 3D printing and guides for adding the robotic functions available online.

The benefit of making it open source has allowed for faster feedback on a much wider scale and at a lower cost than ever expected.

The current Handiii model and its open source variant are both designed to be 3D printed, with manufacturing technology key to the overall design.

Having built the arm in SolidWorks, the components are then 3D printed using a desktop 3D printer, allowing for fast and cheap design iterations and testing.

The current model is a work in progress, and although its aesthetics have been greatly worked on in a bid to make it look sleek and futuristic, the arm is still a combination of 3D printed FDM parts.

Exiii founder Genta Kondo

A good fit

At around 650g the prosthetic arm and hand weigh roughly the same as its flesh and bone equivalent, something that according to Kondo importantly helps maintain the balance between limbs, and comfort for the wearer.

Equally, the curved nature of the join between flesh and prosthesis was created to form a better bond for the user than traditional prostheses that attach almost like Captain Hook’s eponymous appendage.

Kondo reassures that the electronic controls – a compact and complex network of motors, wires and sensors – are widely available components. “All the components are accessible, the battery for example is in the arm and is used in a Panasonic digital camera – a global company so you can buy it nearly everywhere.”

He admits that connecting the myoelectric sensor component will require some soldering, but the parts are easy to come by and the model they currently employ costs them only 10 cents to source.

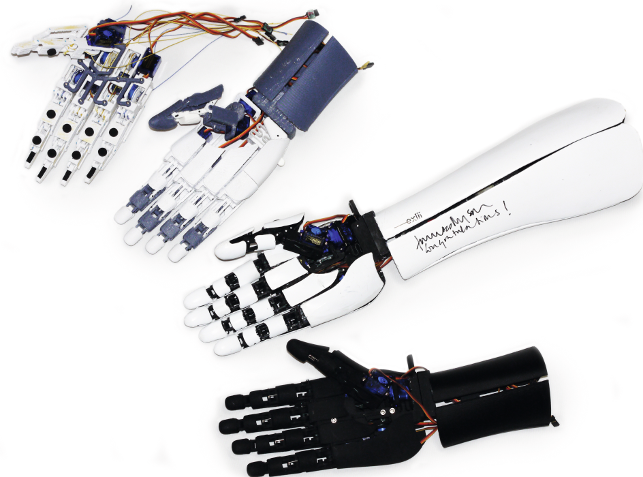

Varying prototypes displaying 3D parts and the internal wiring

In the pipeline

While Exiii is already developing a more rugged, durable and waterproof version, the plan is for it to release a model that still costs less than 10 per cent of the most advanced robotic prostheses.

“I can use this model for demonstrations,” explains Konodo, grasping the arm, “But I couldn’t really use it in daily life. There’s rain and random things happening like people bumping into you. We aim to make it more robust and durable for use over long periods.”

Yet, enabled by the availability of new technologies and the lowering cost of building prototypes, not to mention the active open source community helping to arrive at solutions, the Exiii project looks set to transform not only how prosthetics are designed, manufactured and distributed, but the lives of those wearing them.

How a Japanese start-up is revolutionising prosthetics

Default