Carlin Motorsport’s bespoke facility where cars are built for a variety of championships

If you’ve ever wondered how Formula 1 drivers come to the sport, chances are that many of them have been through Carlin Motorsport’s doors at one point or another.

In fact, as you walk into the UK firm’s reception in Farnham, there’s a Red Bull Formula Renault mounted to the wall with the name ‘Vettel’ emblazoned on the side of the cockpit.

High speed motorsport tops out at Formula 1, but there are various championships on the way to getting there. Many Formula 1 drivers start out with karting and then, if they’ve got the backing in the form of cash sponsors or, commonly, wealthy family, they can start to progress through the ranks.

This is what Carlin Motorsport set out to do when it established in 1999.

https://youtube.com/watch?v=yAM8YKQfglE%3Frel%3D0

“We are an international race team and probably one of the largest single seater teams outside of Formula 1. Our aim is to take drivers from karting right up to the door of Formula 1.

“That means we serve six championships that bridge that gap and at the moment we have 18 cars in total that are racing, and we also have test teams working with younger drivers,” explains Stephanie Tindall, Carlin’s commercial and PR manager.

“If you consider it like a school system, we start at primary school, secondary school, through university and up to your first real job, which is Formula 1.”

Of the current crop of Formula 1 drivers, nearly a third of them are alumni of their Carlin system.

Race to the top

The various constructor specific championships that Carlin supports includes British F3, Porsche Supercup, World Series by Nissan, Formula Renault 3.5, A1GP, FIA Formula 3 European Championship, GP3 Series and GP2 Series.

So, if you think your son or daughter has an interest and talent for motorsport and you’ve got upwards of a 100 grand kicking around, you can talk to Carlin and they’ll provide not only the car that matches the category of racing your child wants to do, but also ensures that your potential podium winner is physically and mentally prepared for the rigours of racing.

However, one of the biggest technical challenges is how these various championships are regulated. While there’s always talk of regulations in Formula 1 each season, the championships are even more restrictive in terms of what can and can’t be done by each team.

Some championships will provide the chassis, engine and brakes, while others will supply the entire vehicle. This means that, even in this realm of racing, the designers and engineers are looking to squeeze every single drop of performance out of the cars for their customers.

It’s within these tight regulations that Carlin drives performance and a means of increasing the vehicle’s performance is by reducing its weight. A way in which Carlin has been able to reduce mass is through its gearbox dog rings, which now weighs in at a mere 140 grams.

If rotational mass can be removed out of the gearbox, more acceleration for the vehicle can be gained, all within the strict rules of the championships.

As Tindall explains, “If we can make a couple of tenths difference per lap, in a junior championship, that can mean the difference between pole position and 15th on the grid – it’s that tight.”

Each car is different and depends on the tight regulations of where it will be raced

Design tools

Without the gargantuan budgets of its peers in Formula 1, Carlin still carries out all of its engineering and design in-house and for this it relies on PTC’s Creo design and engineering software.

It uses Creo not only for 3D design but for finite element analysis and simulation too in the form of Creo Simulate.

However, 2D drawings are still an important part of work at Carlin. Components need to be outsourced and manufactured. They’re also key to communicating to junior engineers how components are assembled/disassembled.

Once again, this is done using PTC Creo’s documentation tools.

“Our business model is that our drivers come to us and pay us to support them for providing a product and service. PTC Creo is essential in making sure we have the edge as we have to design the best product for our drivers, because they are selecting us, we’re not selecting them,” comments Tindal.

Reverse engineering

In the design process, the engineering team also carries out reverse engineering.

Within the championships, the majority of chassis are supplied by Italian outfit Dallara. While the teams are supplied with a basic handbook, they receive little information about the form of the chassis.

As a result, Carlin works with Physical Digital and uses its 3D scanning tools to capture the chassis in digital form.

Using that data as a basis to build models in Creo, areas for improvement and adjustment can be found.

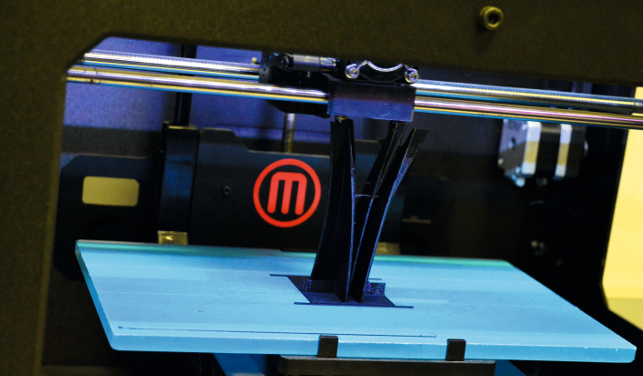

When it comes to model making, this is also predominantly carried out in-house. Carlin relies on its tried and tested Makerbot to build scale models for wind tunnel testing.

Interestingly, this is something that few teams operating at this level do and as such Carlin feels it gives it a distinct advantage over the competition.

The in-house Makerbot builds scale models for wind tunnel testing

Looking to the future

For the future, Carlin is looking to supplement its existing driving simulation facility with augmented and virtual reality to allow both the design and engineering teams and the drivers to gain a richer and more immersive understanding of the factors that influence both the performance of each vehicle and the drivers putting them through their paces.

As Tindall concludes: “As we provide a product and a service, we’re only as good as our last race. If you’re not winning and not getting podiums and not showing drivers how they can improve in our cars, then they’re not going to come to us.”

The race for F1 glory often passes through Carlin Motorsport’s formula for success

Default