A youthful company is exploiting technology that’s 200 years old. Steam is the new green for Clean Power which is developing a method to harness wasted heat energy from a vehicle’s exhaust system. The company’s compelling message for businesses facing spiralling fuel bills and ever tightening environmental regulations is to optimise fuel consumption whilst minimising pollution.

Clean Power is counting down to May 2010 and the launch of the first of its innovative products – an exhaust derived power source and retrofit for refrigeration unit truck trailers. Exhaust emission can account for up to 36% of the calorific value of a truck’s fuel and the company plans to use this energy to produce free electricity from superheated steam.

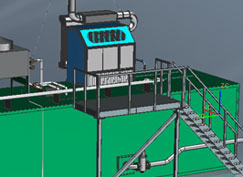

This hybrid fuel technology will also be used to provide a way to capture the wasted energy from the combustion of methane, a major greenhouse gas found on landfill sites, and use it to generate electricity that can be fed into the national grid.

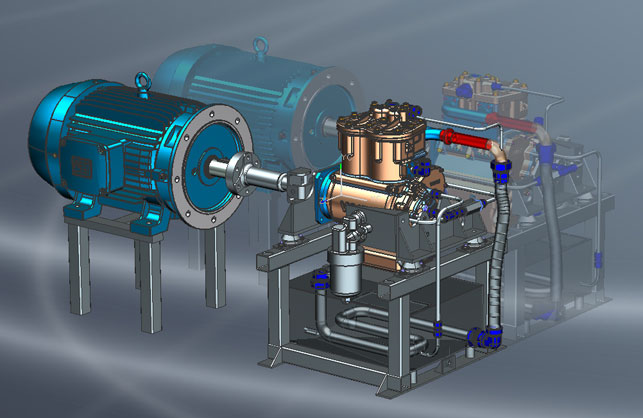

Steam expander connected to a 30KW motor

Clean sweep

With full production due to begin in 2011 Clean Power Technologies needed to make the transition from small research organisation to international manufacturing company. “We wanted to travel smoothly from innovative idea to customer delivery,” states Director Mike Burns. “A one month delay could cost us hundreds of thousands of pounds so at an early stage we decided to create the complete design, analysis and production environment that we knew we would ultimately need.”

For 3D modelling Clean Power uses NX 6 and for data management it uses Teamcenter, both from Siemens PLM Software and both supplied by TEAM Engineering. “We chose NX because of its strong analysis module and the way it joins up design and production through its machining and drafting package. We selected Teamcenter because we knew we had to control revisions more effectively.”

NX was adopted in 2006. TEAM Engineering worked closely with Clean Power in order to organise engineering data, install a dedicated server and train users when Teamcenter was implemented in late 2008.

Complex assemblies

There are 5,000 individual components in a steam engine and many of Clean Power’s NX models have over 1,000 parts. As Senior Design Engineer Gareth Storoszko explains: “A top level assembly will have several sub assemblies, each quite massive. When I am saving a large assembly I can see it counting down from 5,000 as each part is filed.” Some of Clean Power’s models are imported from partners, “There is often no depth to them but they have numerous surfaces. I may for example only be able to see the top of a bolt but it might have seven or eight facets. We also download fittings from suppliers and whilst these are surfaces only they carry a lot of weight.”

It’s critical that we can reduce weight and cost to a minimum in our designs so we need to be in a position where it is easy to see and manipulate model detail

Managing design engineer, Paul Burns, agrees that using CAD involves working with a huge amount of detail. “I’ll have various icons and open menus around the model because I need a selection of tools and assemblies to hand at any time.”

Not surprisingly Clean Power decided to supply its two designers with large screens so that they could see models and drawings with complete clarity. 30-inch monitors were purchased early in 2009 but, according to Paul, problems started as soon as these were plugged in.

“Our workstations are both Dell Precision computers to which we have added more memory. We knew they were reliable but with the new screens we faced immediate problems. Any time I attempted to rotate a model everything slowed right down or completely froze. At first I assumed it must be my workstation, despite that fact that it has a very high specification of 32GB and that it was OK when I used a simple office application.”

Having made various hardware adjustments with no success Paul contacted TEAM Engineering for advice. “They had previously described our models as ‘humungous’ and they had given us lots of tips on how to load up files without having to manipulate all the associated data so we knew we were following best practice. Together we tried a dozen different approaches with the new screens and in the end we proved that the graphics card was causing the problem. The size of the monitor was just too large for the card.”

Clean Power’s IT specialist Steve Wilson says, “TEAM were great. They recommended an ATI Fire GL V8650 from AMD and even arranged for us get one on loan. The card is obviously very sophisticated, it comes with its own power source and cooling system.”

CESAR (Clean Energy Separation And Recovery) system on top of a landfill methane power generation unit

Smooth operator

Paul is extremely satisfied. “With the new card I can quickly switch from model to model with no stalling and no crashing. I was having problems for over two months and eventually I began a log: towards the end of that period my computer was freezing three to four times a day, every single day. The amount of time I have now regained is enormous. It used to take five minutes to reboot, ten minutes to open the CAD system and five minutes to load a model. In addition I would have lost my train of thought each time. Over a day that could add up to a couple of unproductive hours.”

The card also enables better demonstrations. “Our investors visit regularly to see how designs are progressing and it works well to be able to show a model on a large screen” said Paul. “It was very awkward when my workstation crashed in front of them. The card is well worth the money. When I run a model I now have complete confidence and total consistency of performance.”

The reliable large screens also enable easy collaboration with partners. “We do have a projector” comments Paul, “but it is easier for designers to sit around a monitor to have a discussion. We are, for example, working with a Swedish company that manufactures steam locomotives and as specialist engineers they are signing off our heat exchanger. One of their experts comes here to review our designs with us to ensure that we are going to have a safe working product suitable for road use.”

Being a small company the productivity and accuracy of Clean Power’s four engineers is paramount. “The ATI Fire GL V8650 from AMD gives us the speed and visual clarity which are essential for our business,” says Mike Burns. “It’s critical that we can reduce weight and cost to a minimum in our designs so we need to be in a position where it is easy to see and manipulate model detail. We really cannot afford unproductive waiting time.”

www.cleanpowertech.co.uk

www.ati.amd.com