From bean to cup, coffee involves one of the world’s most intricate value chains. Gruppo Cimbali is setting out to perfect the process with the aid of digital twin technology

Precision is key to crafting a consistently high quality cup of coffee. Nowhere is this more important than in the final leg of the value chain – production. The grinder must deliver the exact grade of beans each and every time. The espresso machine must heat and pressurise water to exact specifications.

Gruppo Cimbali is aiming to perfect this final step before customer consumption. The company is incorporating more transparent processes and data in its product development, as part of its wider commitment to sustainability and making sure nothing goes to waste. The end goal, however, remains the same: great coffee.

Making coffee is energy intensive. Even professional coffee machines can lose more than 300W of power through heat loss alone. The peak load power requirements of many espresso machines exceeds 6 kW.

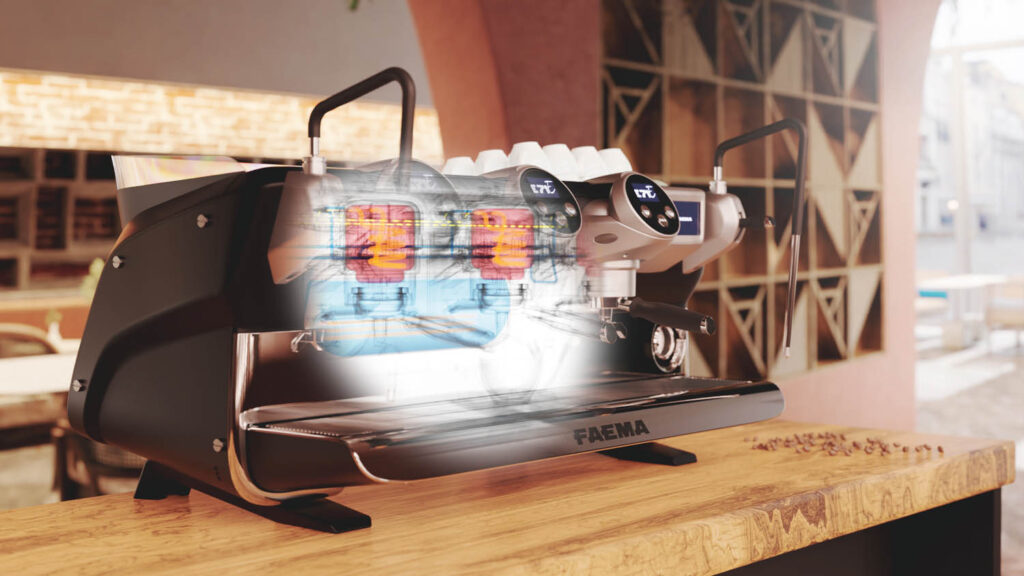

This is where Gruppo Cimbali, which includes brands such as La Cimbali and Faema, sees digital twin technology introducing a hot shot of efficiency. Key requirements such as reducing energy loss, balancing peak loads and enabling its team to develop more efficient operating strategies can all be achieved with extensive virtual prototype testing. And that means better optimised products and faster development, making each cup of coffee more sustainable.

Maurizio Tursini, chief marketing and solution officer for Gruppo Cimbali says that new technologies are key to creating a unique user experience. “By providing sleek, reliable, energy-efficient products, we are an industry leader,” he says, speaking from Gruppo Cimbali’s headquarters in Binasco, on the outskirts of Milan, Italy.

“The primary focus of the physics-based digital twin is the physical modelling, simulation and optimisation of the thermodynamic process, including a real-time, human-in-the-loop view. This helps us make better products faster.”

To do this, the engineers are using Altair’s comprehensive One Total Twin platform, in order to create physics- and data-driven digital twins that can be connected. “This allows us to optimise functionality at the system level for the entire design and product lifecycle,” says Tursini.

Time to refuel

Gruppo Cimbali executives say that the company’s optimisation process has already improved the performance and efficiency of its espresso machines and helped reduce energy loss in its latest generation of products.

Compared to its prior E71 model, featuring traditional thermal technology, Tursini says its engineers achieved an improvement of 20% with an independent boiler structure. For its new E71e model, based on this improved technology platform, another 25% of energy savings were achieved through virtual prototyping.

The goal is to add new technical solutions to future machine generations as the company continues on its journey towards a target of 40% energy loss savings.

“In addition, the reduction in physical testing means we require fewer prototypes, can reduce prototyping costs and better define the design exploration space, which reduces overall material and energy usage,” adds Tursini.

“And lastly, the digital twin workflow has significantly shortened the length of the development cycle,” he says.

“Our digital twin approach, with the help of Altair and their unique One Total Twin platform, has streamlined our processes and improved our machines. Together, we’re developing more efficient, more sustainable ways to enjoy coffee.” Something we can all drink to.

This article first appeared in DEVELOP3D Magazine

DEVELOP3D is a publication dedicated to product design + development, from concept to manufacture and the technologies behind it all.

To receive the physical publication or digital issue free, as well as exclusive news and offers, subscribe to DEVELOP3D Magazine here