From wildfires to Covid-19, a respiratory mask for children was desperately needed. Flo Mask’s creators explain how using digital design tools its team were able to quickly build a design to fit every child

During the 2018 Camp Fire wildfire in Northern California, the entire San Francisco Bay Area was blanketed in toxic smoke for two long weeks.

Suddenly the Bay Area had some of the worst air quality in the world, and local parent Kevin Ngo was greeting his children home from school each day complaining of nausea and headaches.

“As a dad, I desperately wanted to protect them from this health crisis, so I started searching for a solution,” Ngo says, explaining how N95 grade masks that would help filter the smoke from the air were not available for children.

“The irony here is that kids are the ones most impacted by air pollution, yet there were no solutions to protect them.”

Ngo, with over 15 years experience in developing consumer products, set about designing a solution – Flo Mask – with the main challenge facing him being the variation in children’s face shapes to create a one-size fits all respirator.

Even with a flexible gasket forming a seal around the mouth and nose, Ngo knew that they would have to find a shape could fit the majority of different sizes and ethnicities. And the only way to find this would be to 3D scan enough faces.

“After a tremendous amount of research, I found that the Eva 3D scanner from Artec 3D could scan a kid’s face within a few seconds with an accuracy of 0.5mm. It was exactly what we needed since most kids can’t sit still for long!

“At that point, I started scanning elementary aged kids across various ethnicities to ensure we were designing for everyone.”

With the 3D scan data collated, the team went through the time intensive process of aligning each scan, using the front of the lips as the anchor point.

With all the scans in place, it was possible to identify a single shape that could accommodate all the kids.

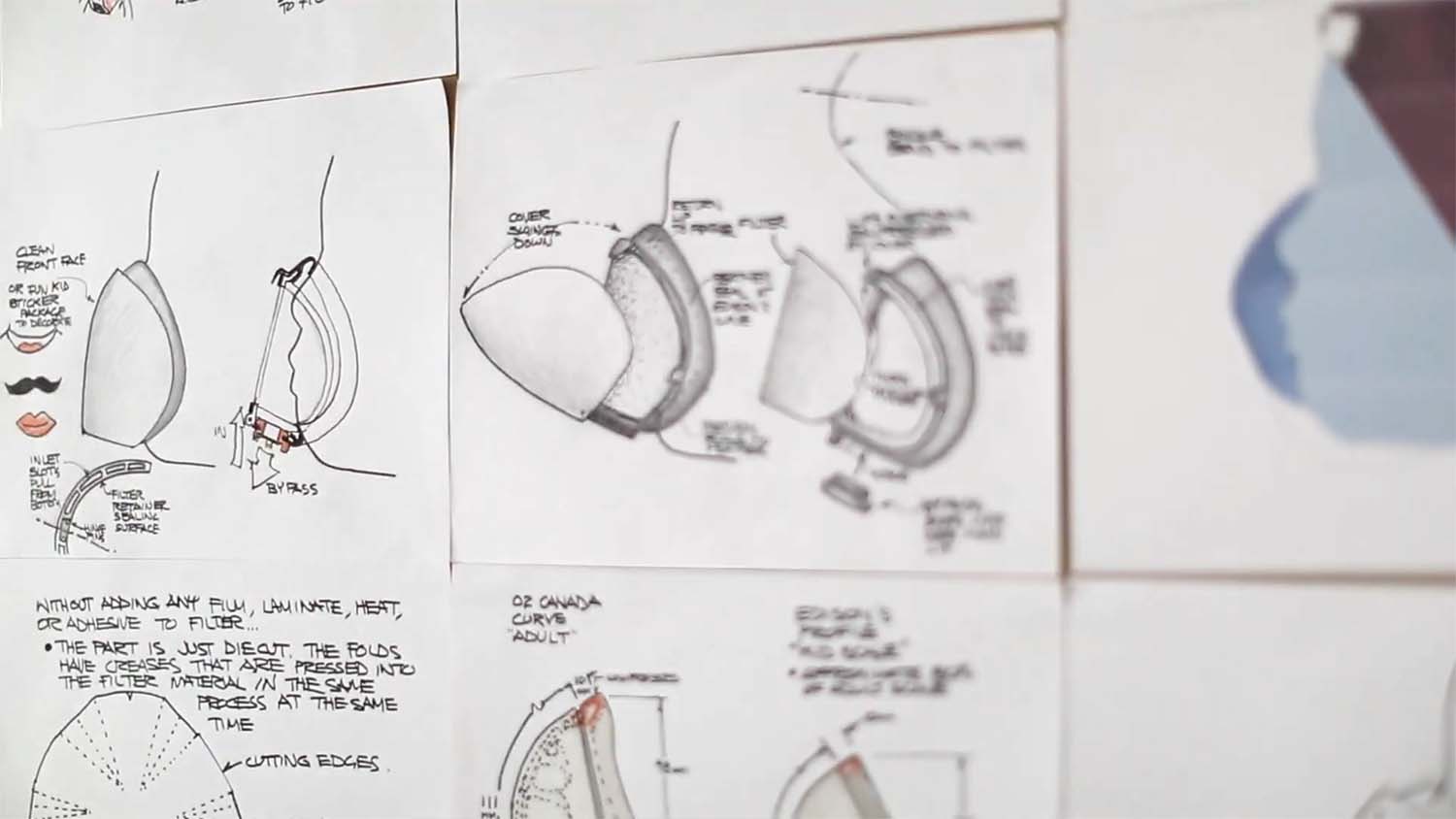

Using Rhino and PTC Creo, the team built a 3D CAD model of the respiratory mask for children that could be tested.

“Of course, digital designs aren’t always the same as real life, so we went through many rounds of 3D prints to test on real kids,” Ngo intervenes, explaining that they started with home 3D printers, before approaching a prototyping bureau with Stratasys polyjet technology, that could simulate the mask and silicone gasket.

Through this rapid prototyping process, the shapes refined to account for interference with sensitive areas of the face such as the lips, focus on slimming down the depth of the mask to allow for better peripheral vision, and to verify the necessary airtight seal.

Moving on to soft tool moulds for the final few engineering challenges, once everything was locked-in, the product was ready for production tools.

Flo Mask uses liquid silicone rubber to create a pillowy gasket that helps fill the contours of the face for a solid seal.

With good respiratory comfort, the design also features generous air flow openings, allowing the wearers little lungs to breathe easily and comfortably through a medical grade filter layer.

The aesthetics of Flo Mask were also heavily considered to gives it an iconic look, one that swerves kiddy colours or characters. “We wanted to go with a look that was a bit more elevated, yet maintained the playfulness,” says Ngo.

“This is demonstrated through the clean surfaces of Flo Mask, but with generous rounds and oversized buttons that anchor the straps. And because breathability was such a core focus for us from the start, we wanted a bold statement by leaving the front cover fully exposed to maximize air flow.”

Halfway into the Flo Mask development process, the Covid-19 pandemic took over the world, “so we knew Flo Mask was needed more than ever” says Ngo.

“Our team makes products for a living for some of the biggest brands in the world, so we’re always striving for perfection. To this day, we’re still thinking of ways to improve Flo Mask.”

With air pollution dogging cities around the world; wildfires a regular feature of summers on the US west coast, and the global pandemic showing no signs of slowing, respiratory devices like the Flo Mask are going to become increasingly necessary. Until solutions to these greater challenges can be found, at least children can breathe easy.