Valk Welding’s Automatic Robotic Programming (ARP) solution for high-mix, low-volume production has seen programming times slashed through use of Oqton software, using artificial intelligence to learn from an operator’s best practices to refine processes for future parts.

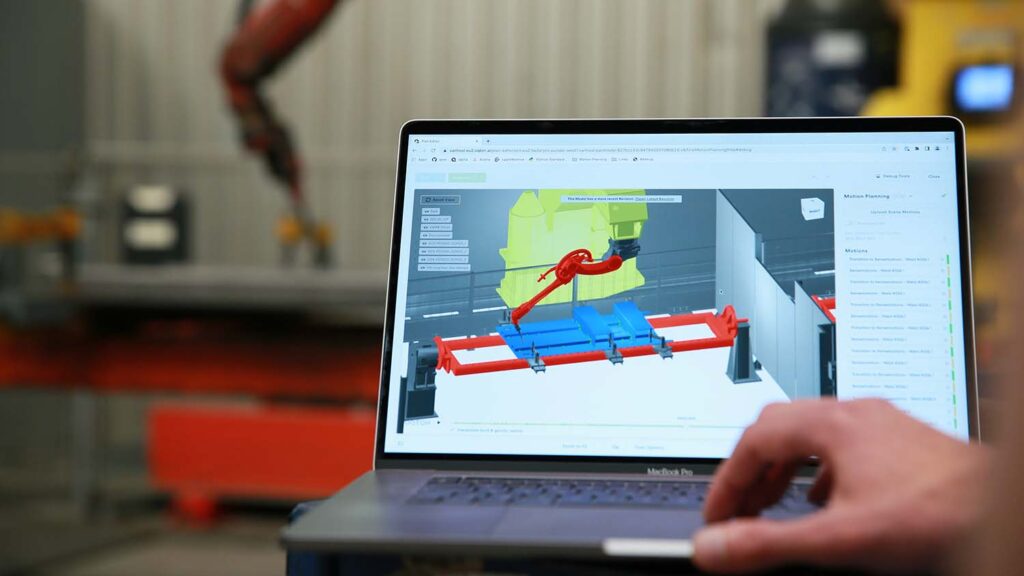

The Valk Welding ARP powered by Oqton autonomously generates robotic welding programs directly from 3D CAD files, reducing the need for costly programming. As a result, welders can use the software without previous knowledge of robots or 3D geometry.

Valk suggests that this makes it an ideal solution for low volume production using robotic welding for steel fabrication sub-contractors who are manufacturing lifting platforms, transport pallets, fencing, and automotive sub-frames among other products.

Automated robotic welding is capable of being three times faster than manual welding while also reducing the manual labour costs needed – important as more welders are retiring each year than new welders coming into the industry.

Both Valk and Oqton say that the new techniques and processes being jointly developed are intended to enhance the utilisation of automated robotic welding for unique or small batch production that was previously only economically viable using manual methods.

Peter Pittomvils, Valk Welding Group CCO, said: “Our market lead in 100% offline programmable welding robots is ready to make the jump to the next level! Besides our own projects, we also support Oqton to all other Panasonic system integrators to also serve their customers with this great solution and our experience.”

The American Welding Society (AWS) says the average age of a welder is 57, and by 2024 the AWS estimates there will be a 400,000-job deficit in the welding industry. Additionally, the availability of welders in Europe is decreasing by 2% per year and that number will only increase in the coming years. While the shortage of welders has existed for many years, the shortage of robot programmers with welding knowledge is also highlighting the need for an automated solution.