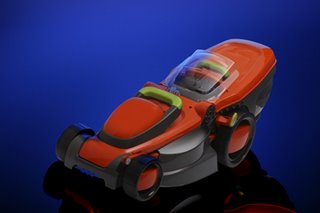

This little Flymo is a prototype put together by ARRK comprising of 25 CNC components in ABS and clear acrylic, whipped together in under a fortnight that allowed for actual field trials to cut grass.

Garden tool manufacturer Husqvarna called upon ARRK to assist in the development of their new rear collection lawnmower, the Multimo 360XC.

After successful trials ARRK was then commissioned to produce vacuum castings to build 15 fully assembled lawnmowers to be used for photo shoots and marketing meetings.

The components were fully finished, textured, assembled and then delivered to the client within four weeks, just in time for the product launch.

Related articles:

MakerBot Carbon Fibre editions added to Method 3D printer line-up

SolidWorks 2013 & what constitutes a good release?

Artec 3D unveils first AI-based handheld 3D Scanner

Hidden with beauty - Geometric screens designed to develop outdoor spaces

Designjunction supports dyslexia in design with a curated exhibition

Hexagon Recreate offers streamlined reverse engineering

Winners of new IET photography competition show dynamic and creative side of engineering

WATCH // CRL's prototyping lab does the work while you ease back

Advertisement

Advertisement