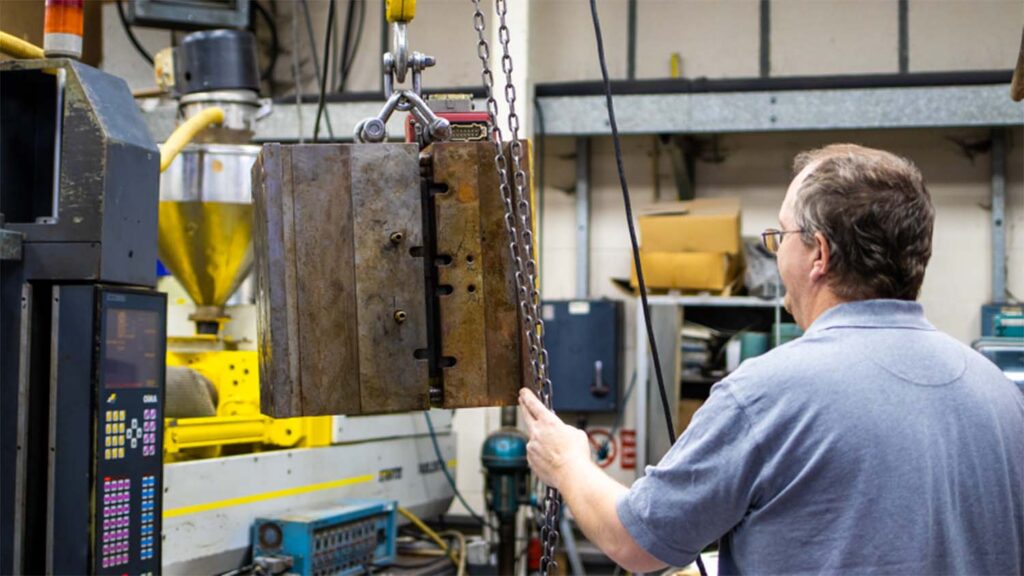

IDC has announced the acquisition of Naiad Plastics, an injection moulding company based in Littlehampton, UK, in a move that looks to benefit its clients small to medium volume production.

For nearly 50 years IDC has been involved in designing thousands of products. Many of which have included injection moulded parts, and as a result, design for injection moulding has become one of IDC’s areas of expertise.

“During this time we have developed many strong relationships with some extremely good injection moulding companies around the world including in India, China and across Europe,” said an IDC spokesperson. “These valuable partners will continue to be a great choice for many of our clients. However, for customers looking to manufacture in low and medium volume – typically in the range of 1000 to 100,000 units per year, the cost and logistics of managing Far Eastern suppliers can be difficult to justify and manufacturing in the UK has some significant advantages.”

IDC’s statement goes on to say that is without doubt that the combination of Brexit and COVID has further accelerated this trend.

In order to assist its customers’ wants for a smooth and efficient transition from design to production, this move makes a great deal of sense. By taking ownership of the full process from design, right through to production, it should enabling them to avoid the difficulties associated with the handover of responsibility and provide clients with a more responsive and fully accountable design partner.

IDC also state that another driver of the decision is the need to use plastics more sustainably.

“Plastics have revolutionised our world, improving people’s quality of life and transforming healthcare, but we are also very aware that excessive use and irresponsible disposal of plastics can cause great environmental harm.

“It is clear that the way we use plastics and the types of plastics we use will need to change.”

With its own production facility, IDC says it will be able to take the lead in this change and this process is already underway. A large percentage of Naiad’s production is already made from recycled polymers with plans to go further by adding bio-based and compostable plastics to the manufacturing capability, with the positive sustainability metrics immediately passed on to clients.

The company also cites the value of being able to visit suppliers in person and inspect products and production lines, and then sit around a table to quickly solve problems. Add to this the benefit of reduced shipping times and smaller inventories, then agency clients can start to see further benefits.

“Our mission at IDC is that ‘We innovate to create successful products which improve peoples’ lives’,” continued the company statement. “As part of that focus on creating successful products, we are not only passionate about product design, but also the manufacturing processes required to make the products.

“The next few years will be an exciting time for UK manufacturing and at IDC and Naiad we look forward to playing our part.”