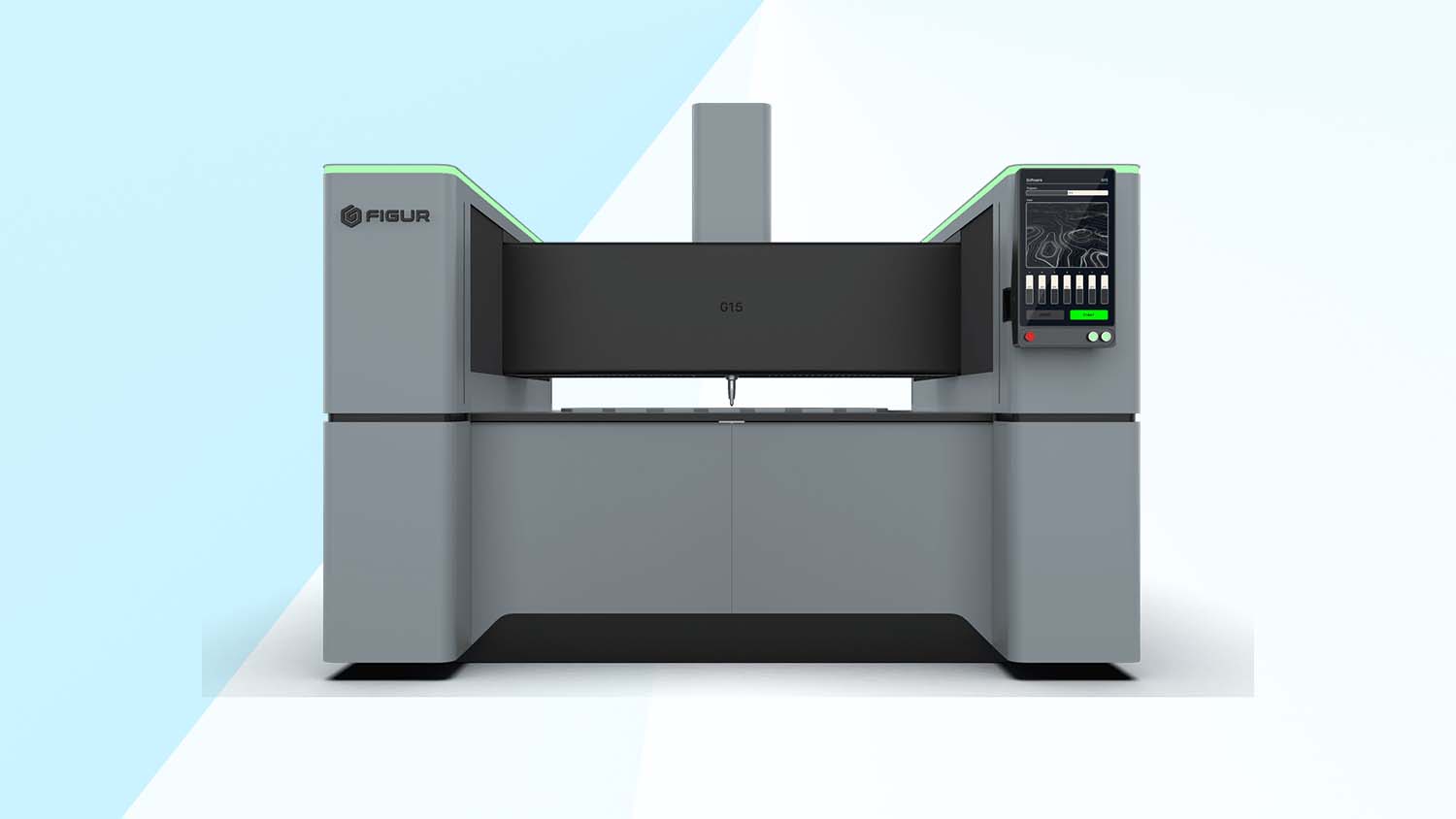

Figur G15, a system for shaping standard sheet metal on demand directly from a digital design file, has been launched by Desktop Metal – requiring no custom stamping tools, moulds, dies, or presses.

The Figur G15 launch model has an XY forming area of 1450 x 1000mm and can process forms up to 400mm in the Z direction. A wide variety of metals and sheet thicknesses can also be processed – including steel up to 2mm thick and aluminium up to 2.5mm.

The technology is claimed to be capable of producing parts such as a common automotive exhaust muffler – which would traditionally require the purchase of a $150,000 die with a three month lead time and a quantity of 1,000 parts, at around $160 cost per part, including materials – at approximately $10, primarily for materials and labour.

“This system allows you to be nimble in your design process,” said Chris Hamm, a digital fabrication engineer at Figur. “With our machine you are able to develop that car part, or that clean part quicker.”