Arris Composites is looking to pioneer next-generation composites for mass-market applications through the use of its new Additive Molding process.

The strongly backed start-up develops continuous carbon fibre composites that can be combined with other materials in a high-speed process that integrates 3D printing and traditional high-volume manufacturing.

Arris Composites goes on to claim that the technology has broad benefits across many applications and markets enabling smaller, thinner, lighter, stronger products and entirely new approaches to product design and system architecture.

Founded in 2017 by manufacturing veterans, Ethan Escowitz, Riley Reese and Erick Davidson, Arris’ manufacturing technology also looks to solve the environmental concerns facing the composites industry: Arris embraces the cradle-to-cradle philosophy of an environmentally-sustainable product lifecycle in contrast to the current wasteful cradle-to-landfill composites process.

Using thermoplastic-based composites, low energy processing, and a novel design methodology, end-of-life products can be re-shaped into the products of the future.

Most intriguing is how Additive Molding mimics how nature aligns fibres – much like how trees build structural strength.

The process allows designers to align glass and carbon fibres along the stress vectors running within a complex three-dimensional part. The fibres can also be precisely aligned around attachment features.

“Aligning continuous carbon fibres with force vectors along all three axes is critical to increasing structural performance over metal while significantly reducing weight,” explains Arris Composites CEO Ethan Escowitz.

“The ability to deliver those benefits at mass-production volumes and costs opens the door to a broad number of applications across industries as diverse as consumer electronics and sporting goods to aerospace and automotive.”

Arris states that its Additive Molding process is a completely automated process, beginning with raw material input through to the de-moulding of the finished quality part

It starts with dry glass or carbon fiber tow, which is then coated with a thermoplastic resin (prepreg).

Proprietary robotic equipment forms and assembles the prepreg into precise locations within a mould.

Then, heat and pressure are applied to yield a final part with the high-quality surface finish and tolerances of moulding.

In Carbon Fiber We Truss

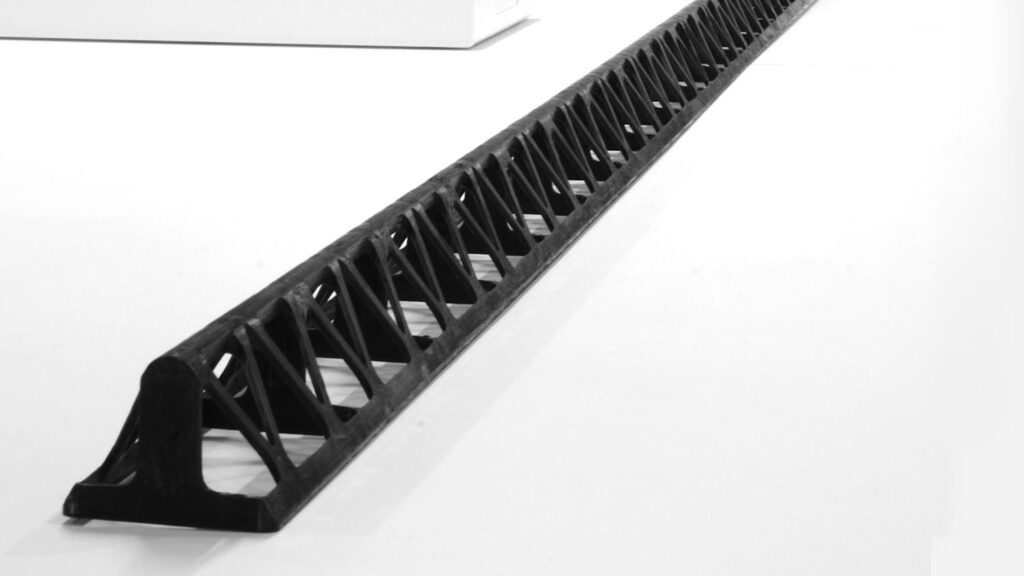

Arris recently demonstrated the large-scale capability of its technology with the production of a 2.4m continuous-fibre truss structure.

Trusses are an ideal shape for any high-strength, lightweight structure as is the case in wind turbines, planes, cars, all the way down to bikes and scooters.

While ubiquitous in buildings, composite trusses have seen limited use in these applications due to high costs associated with processing and waste using existing composite manufacturing techniques.

Arris Composites claims that its process makes complex, structural shapes like trusses possible at mass-production volumes and costs.

In addition to delivering the structural benefits of continuous, aligned-fibre composites at scale, Arris’ manufacturing process looks to add extra value, through the embedding of electronics components alongside separate materials – carbon fibre, metals, wire, glass, etc. – into specific sections of parts.

Arris has also teased its own unique suite of software tools, called SpecificDesign, for in-house design collaboration and engineering teams to optimise the benefits of the process, which we’re looking forward to seeing soon.