The design and manufacture of jewellery is no longer the laborious task it once was, thanks primarily to the abilities of companies like PP Manufacturing to work with the latest technology.

The use of 3D software and rapid prototyping (RP) machines in jewellery design has continued to grow throughout the industry, and because it gives the designer creative freedom this positive adoption is likely to continue.

This is evident at the heart of the British jewellery industry, London’s Hatton Garden. On an entire street of gleaming gold and diamonds, set behind the storefront bling is a small but industrious CAD bureau that specialises in jewellery design and manufacturing.

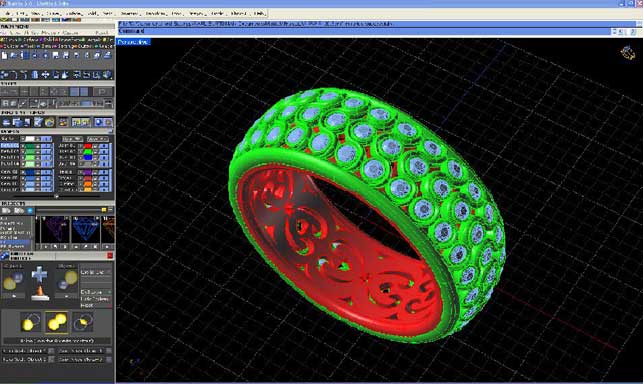

Gemvision Matrix is used by PP Manufacturing to create new jewellry designs

PP Manufacturing began life nearly five years ago. In 2006 it moved on from engraving technology into full CAD, and although admitting that it fell into it by chance, it was a great time to begin. The company now has the right experience and know-how to take a lead in a fast developing area for 3D design technology.

From its small workshop, Paul Burton and Paul Thurston, the founders of the company, have built their business through reputation, and being situated in the nerve centre of British jewellery production they have steadily built their business.

“It’s through word of mouth that people will come to us,” explains Paul Burton. “Customers come for either the whole job – for instance they bring in a sketch, we do the drawing, make the wax cast, and produce the finished piece – or some will come along with a file and we will just make the wax cast for them.

Stepping into the office the advanced machinery stands out from those areas more traditional to a jeweller’s workshop, although both are needed to complement each other. A piece made from a RP machine still needs to be hand finished, and the artisan skills associated with the craft are certainly in demand.

Since setting up, the company has made an effort to try and maintain the right balance of machinery, software and traditional skills to give customers what they want.

The role of CAD

Working in Gemvision Matrix, a dedicated 3D jewellery design software, Paul spends most of his time building the 3D models to be cast in wax. The software offers specific toolsets for a jewellery designer, helping to make it quick and efficient for selecting styles, shapes and gem settings. Alternatively a designer can start from scratch and draw out all the shapes themselves.

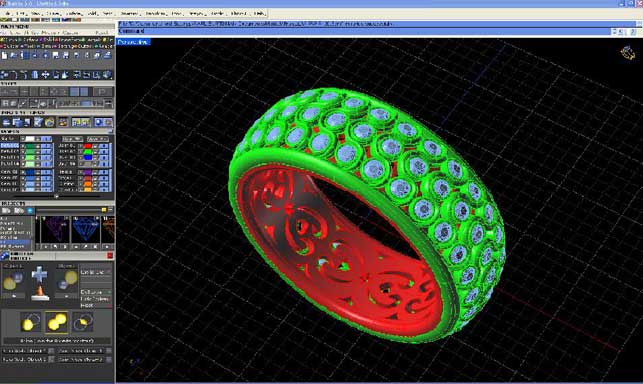

Rendering is done using Matrix’s in-built Vray renderer

Being an early adopter, Paul found it had the edge over other jewellery software and maintains that he still finds it best for PP Manufacturing’s workflow. “Coming to this from previous software, which was engraving software for us, it’s quite similar, being very basic,” he says. “Although it’s no use learning how to use it and then using it only once a month. I sit on this all day everyday.”

The final design can then be rendered using Matrix’s in-built Vray renderer, specifically designed for jewellers, giving a quick choice of colour variations for precious metals. However Paul has to remind customers that the impressively sharp edges of the render will have to be smoothed off in reality to make it safe to wear.

From here the designs are ran through ModelWorks inside SolidWorks to create the toolpaths for the print before being set to the SolidScape T66. Similar to an inkjet printer, there are two inkjet heads, one depositing a cyan thermoplastic material (InduraCast) that acts as an investment casting wax. The other is a sacrificial wax (InduraFill) that is dissolved when the model is complete. The models are then cleaned up and the finished result is ready to cast.

Mould production

The company was the first to take on a Revo Mill in London, and as a result can produce fine detail casts much smoother than the ‘build-up’ process of the SolidScape machine. Essentially a fine detail 4-axis milling machine, it transforms wax blocks into detailed moulds with a surface “as polished as glass” when completed. By having both machines PP Manufacturing can offer a wider range of surfaces, from rings and cufflinks, to pendants and medals.

A designer can start from scratch and draw out all the shapes themselves

The company is a popular choice for customers from different backgrounds: the big jewellers of Hatton Garden frequently use the company to meet a request of a customer; a person with their own design might walk in off the street, or a jewellery designer at the other end of the country might send over a CAD file for a wax cast to be made.

“There are quite a few people on Hatton Garden that use CAD software, and more and more people are buying into the technology,” says Paul, explaining how the company fits into the surrounding market. “We were the first to have the Revo Mill and it just offers something different from the SolidScape machine. Not many people have both sets of machinery.”

The technology might be new and the product may be small, but as PP Manufacturing proves, the end result has to maintain the same quality and craftsmanship that traditional methods have always offered.