Stratasys’ manufacturing ambition has seen it launch three new systems as it looks to cement its position in the end use parts additive manufacturing sector – including the first rebadging of its recent acquisitions.

A Stratasys ‘labeled and upgraded’ Origin One, the first of its powder-bed fusion H-Series and a new Fortus model make up a considerable launch for Stratasys as it attacks the three key sectors of current polymer additive manufacturing.

“We are accelerating into the Additive Manufacturing 2.0 era, in which we see global manufacturing leaders move beyond prototyping to fully embrace the agility that 3D printing brings to the entire manufacturing value chain,” said Stratasys CEO Dr. Yoav Zeif.

“The disruptions we are seeing today on both the supply and demand side of global supply chains are a clear sign that the status quo isn’t working. Additive manufacturing gives companies the total flexibility to decide when, where, and how to produce parts.

“That’s why we’re committed to being the complete provider of polymer 3D printing solutions for our world-class customer base.”

Stratasys Manufacturing: The new models 101

The detailed and intricate one

The Stratasys Origin One looks to fill the resin-shaped gap missing from the company’s portfolio, adding DLP speed and certified third-party materials.

The latter element is a big shift for Stratasys, which like the other cornerstone of 3D printing, 3D Systems, has long held on to its materials market while new pretenders have abandoned the practise in order to encourage adoption.

The new Stratasys Origin One 3D printer uses the existing P3 technology and what it is calling a ‘software-first’ architecture to produce parts at volume.

Stratasys suggests that its engineers have been tinkering around with the hardware since acquisition to optimise ‘virtually all aspects of the system’ – mostly it seems to improve reliability and performance.

Stratasys Origin One also signals the first over-the-air (OTA) software updates, allowing feature improvements to be buzzed directly to the hardware.

The system, its post-processing system and related software should be available from May 2021.

The one to challenge HP

With the launch of its Multi-Jet Fusion technology, HP waltzed into the 3D Printing market and nabbed a huge share of the Nylon-loving crowd.

As a counter, the Stratasys H-Series of printers was announced in March, having been working away under the cover of Beta darkness in various facilities since the beginning of the year.

Powered by SAF technology developed in-house with Xaar, the first model to be released is the H350 and from what its engineers are saying, it has been designed for part packing and high throughput from the very beginning.

According to Stratasys, a 6-10% density is ‘the standard for typical powder bed fusion processes’, while SAF offers a standard density of 12%, and can even support densities peaking at 23.5%.

Like The Origin One, the materials will be opened up to ‘certified partners’, but at launch alone there is the vaguely eco responsible High Yield PA11 derived from sustainable castor oil that has passed some initial tests, like ISO 10993-5 for cytotoxicity and UL94 HB for flammability.

Built for production, the H350 features MT Connect to be manufacturing floor ready, while Materialise Magics, Siemens NX, and PTC Creo are all listed as compatible with the Stratasys Build Processor.

Stratasys will also provide GrabCAD Print support in the future for build preparation.

The sub $100k ‘proper’ Fortus

Stratasys has long had its own workhorse technology – the grandfather of factory FDM – the Fortus.

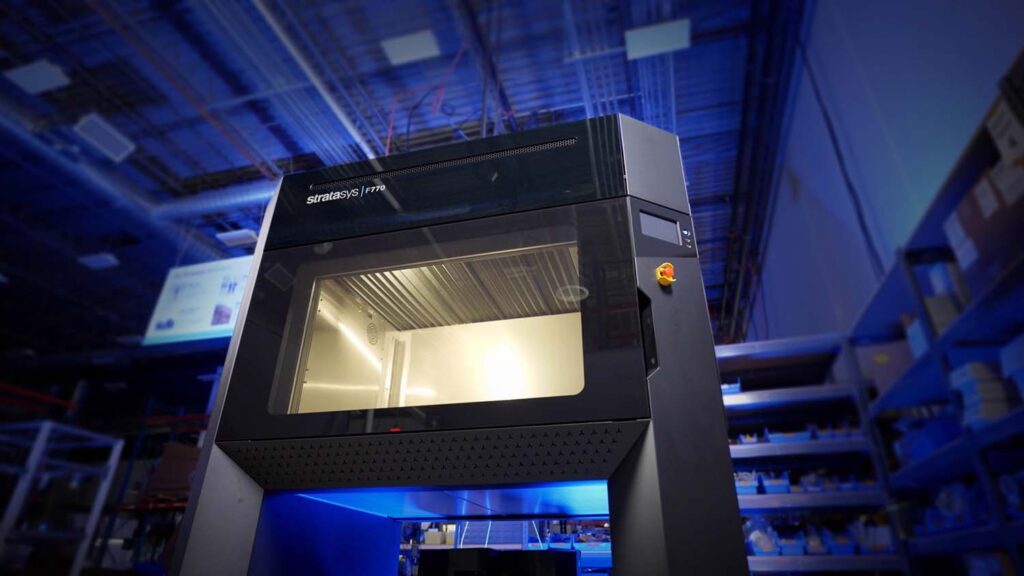

Snipped-down to a marketing friendly F-Series moniker, the newest arrival is the F770, that looks to build on that reputation for tough, big parts, but at a sub $100k price point.

Soluble support material is retained, simplifying post processing, while GrabCAD Print software and MTConnect standard and the GrabCAD SDK is also in place, just like on the big F900.

As non-Americans, we’re unhelpfully advised that the build area is ’13 cubic feet’ with a ’46 inch diagonal’ – although what we can take from that is that it can print large, long-ish parts that are a real step-up from what’s available from the Fortus 450. [Helpful edit: it’s 610 x 610 x 1,000mm]

Unlikely to have fresh hoards beating a path to industrial FDM, the F770 looks like the perfect fit for ‘shops already running Fortus machines that are looking to scale up production with dedicated 3D Printers running a couple of materials.

It’s available to order right now and will ship starting in June 2021.