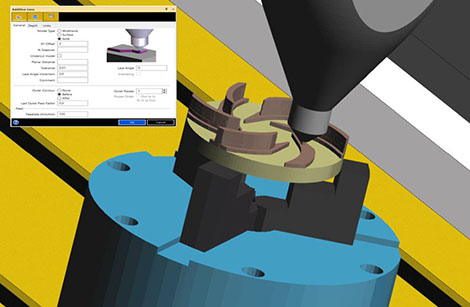

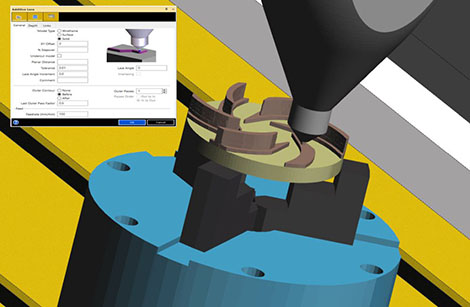

Surfcam 2019 features a dedicated additive manufacturing module

Responding to the increase in hybrid manufacturing, the latest release of Surfcam has introduced a new Additive Machining module, to support Direct Energy Deposition methods.

Now offering a dedicated manufacturing cycle, the software accurately guides a laser over deposited powder material to form a shape, from which the part can be machined using Surfcam’s milling cycles to create the final component.

As Surfcam 2019 R1 now offers full ToolStore support for additive manufacturing, shapes can be built using almost any milling cycle, including advanced functions such as rotary and 5-axis simultaneous machining.

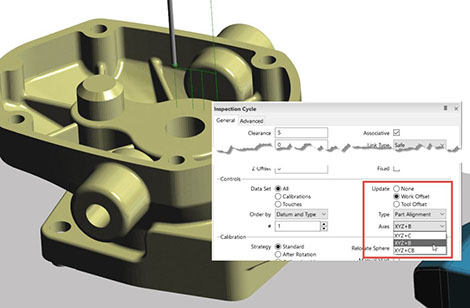

Surfcam’s inspection tools have seen enhancements, with the main coming from the shift to support Hexagon’s libraries

Surfcam brand manager John Buehler says the new Additive Lace cycle is designed to construct geometry on a layer-by-layer basis, depositing a continuous molten bead of material which adheres to the parent material:

“Using the same intuitive dialog interface as all other Surfcam cycles, Additive Lace not only offers the ability to work with various CAD entities but also empowers the user to determine numerous control types, such as lace angle, amount of finish passes, and undercut mode.”

With nearly 30 new individual updates to the software, the R1 release has also introduced three performance boosting enhancements to its machining engine, benefiting both turning and milling operations.

Inspection tools have seen a committed update, despite being only two years old, with 13 new enhancements added to it, with the most important being the switching of its mathematical ‘brain’ behind the product being switched to use the PCDMIS fit libraries supplied by its parent company, Hexagon.

All Geometry Fit calculations, such as measurement deviations and GD&T values, now use a higher level of certified and approved algorithms.