Sentinel-5 Precursor is scheduled for launch in 2016 to monitor the atmosphere from polar orbit. The satellite will carry the Tropospheric Ozone Monitoring Instrument, Tropomi, which has parts redesigned to benefit from 3D printing

The international space agencies are all operating at high speed to nail down suitable new designs to leverage 3D printing.

The process might not be the new Industrial Revolution, but is definitely at the heart of the new space race as different agencies, suppliers and subsidiaries all looking to a future of parts being built by automated printers in space as we jet off to another galaxy.

Yet, for the time being, getting things off the ground for research is the priority, and weight saving measures are at the top of the list – not only are agencies looking to benefit from the costs of low run production parts, but in terms of shaving off weight and adding material strengths.

The new 3D printed mirrors are too late for this launch, but the research will impact future ESA launches

The Tropomi mirror redesign is a current test by the European Space Agency (ESA) with its counterparts at Netherlands research institute TNO to perform this redesign exercise on a 3D-printed mirror, a crucial piece of the Tropospheric Monitoring Instrument (Tropomi) atmospheric spectrometer instrument set to fly on ESA’s Sentinel-5P mission in 2016.

The Dutch-developed Tropomi operates by sifting out particular spectral fingerprints from light that has passed through Earth’s atmosphere, in order to identify trace gases.

To do so, Tropomi requires a pair of precisely distorted mirrors set up to form an ‘optical cavity’ to focus incoming light sharply into a split in the instrument, leading to a selection of light-splitting gratings.

“This represents a demanding target for Additive Manufacturing (AM) reproduction, because the mirror’s precise optical quality needed to be reproduced as well,” explains Laurent Pambaguian of ESA’s Materials Technology Section.

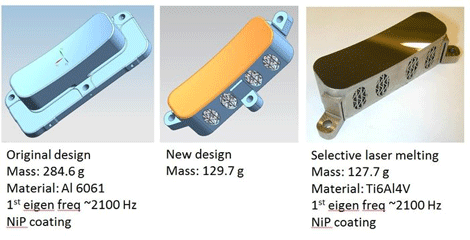

“We took the original mirror design, manufactured in aluminium with a mass of 284.6 grams and a nickel phosphorous coating, and proceeded to redesign it for using selective laser melting AM manufacture. We decided to make it out of titanium, which has a higher maturity for selective laser melting.”

The resulting part was streamlined, with unnecessary mass removed. In the end it weighed in at just 127.7 grams, with the same coating.

That’s a mass reduction of 54 per cent, and despite using a 50 per cent denser material – all without reducing the optical performance of the mirror.

Sadly for the researchers, the design had already been set in stone, so the original mirror design is the one that will make it to orbit, but this trial shows the mass-saving potential for follow-up instruments currently in development.

Experts will be gathering at the ESA’s technical centre in Noordwijk, the Netherlands, on 28–29 October for a dedicated workshop on Additive Manufacturing for Space Applications to discuss the complete AM development cycle and promising early applications of 3D-printed parts.