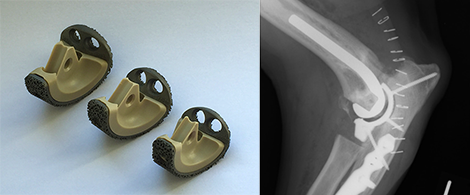

The implants feature a mix of thermoplastic and 3D printed titanium, helping mimic natural canine elbow movement

A designer of human orthopaedic implants has turned his hand to creating a remarkable range of of off-the-shelf elbow joint replacements for all sizes of dog.

Coming in three sizes – small, for dogs of Border Collie size; medium, for Labrador size dogs; and large, for bigger breeds such as German Shepards – Paul Smirthwaite of Osteogen had to combat several design and prototyping challenges.

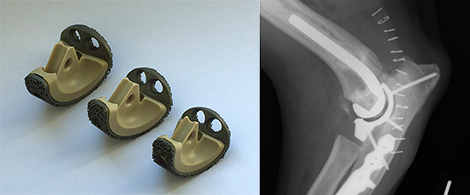

In a healthy canine elbow joint, the ulna articulates with the humerus via a groove called the trochlea, with both bones cushioned by cartilage. Osteoarthritis caused by developmental problems can wear away the cartilage, limiting movement and causing stiffness, pain and lameness.

During the design phase, Osteogen collaborated with super speed prototypers Proto Labs to determine the optimum depth of the design’s thin layer of titanium alloy could be applied to the ulna to minimise bone removal, whilst ensuring maximum durability and reliability for the implant.

“Proto Labs understood our desire to keep the titanium layer as thin as possible,” explains Smirthwaite, “but were able to advise us on the minimum thickness for reliability – which saved us valuable development time in the long term.”

The innovative ulnar implant uses a strong polyetheretherketone thermoplastic bearing which is secured to the thin 3D printed titanium base plate The bearing has a ridge which extends inside the humeral implant and allows an axle to be secured between the humeral and the ulnar implants.

Titanium alloy is favoured as it is strong, and biocompatible. Another major advantage is that Proto Labs’ 3D printing is able to reproduce the honeycomb pattern of the natural bone trabecular, which encourages bone to grow into the titanium pores and produce strong implant fixation.

The speed of the prototyping process meant that several iterations could quickly be verified, while still allowing Osteogen to meet his targeted development deadlines. “Proto Labs is also very proactive in suggesting design improvements,” adds Smirthwaite, “Which again saves time and ensures production is successful and the project is viable.”

The implants are designed to be fully instrumented, to ensure ease and accuracy during the surgical procedure, with all bone-cuts guided by cutting jigs, with the result that the centre of rotation of the prosthesis matches that of the original elbow – putting Fido back on their feet in no time.